1. Introduction

Many studies about New Product Development (NPD) have focused in the identification of critical success factors, that is, best practices that contribute to new product success (Kahn et al, 2006; Song and Noh, 2006; Cooper et al, 2004a; Ernst 2002; Poolton and Barcklay, 1998; Song et al, 1997; Souder et al, 1997; Song and Parry 1996; Montoya-Weiss and Calantone 1994).

Since most NPD research has examined the process mostly in large organizations (Mahemba and Bruijn, 2003; Allocca and Kessler, 2006), and SMEs are different from large firms in several important areas of NPD management, is not clear whether this research can be applied to SMEs.

This research had the objective to explore the issues of NPD in Brazilian small and medium enterprises (SMEs) in the medical device industry. Since the medical device industry is a high technology based industry, this study investigates the relationship between NPD management practices and performance of new product.

Innovative SMEs make a significant contribution in the Brazilian economy, with respect to enterprise development and new job creation. There also is an increasingly important role for SMEs to contribute to economic growth and technological development. SMEs are generally considered to have behavioural advantages that may justify their significant share in product innovation (Salavou and Lioukas, 2003). However, they also have important resource constraints (Freel, 2000).

In Brazil, medical devices large companies with a diversified and highly sophisticated line of products coexist with local SMEs specializing in simpler products or lower cost models geared to import substitution (Souza and Cappa, 2008). Nevertheless, the growing expansion of the local SMEs has been substantial in recent years (ABIMO, 2010).

We tested empirically NPD practices that can be statistically related to successful projects. The starting point of the research instrument applied in the research was a conceptual model based on critical success factors suggested in NPD management bibliography. Recommendations are made for NPD management of the industry studied.

2. Conceptual Model and Hypotheses

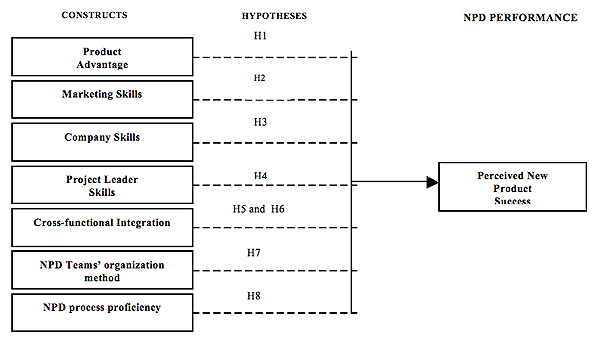

We examined the NPD bibliography for guidance in developing the proposed conceptual model about the influence of NPD management practices on new product success. Song and Noh (2006), Thieme et al. (2003), Lee et al. (2000), Song et al. (1997) and Maidique and Zirger (1987) developed models that explain these relationships. Figure 1 presents the conceptual model that guided this study.

This theoretical framework was based on Brown and Eisenhardt's model (1995), Song and Parry's causal model (1996), Souder et al. (1997) and exploratory interviews conducted by the authors with managers from Brazilian medical device companies.

Figure 1. A conceptual model of new product success

The dependent variable of the conceptual model is the success of a new product. Drawn from the examination of the NPD bibliography (Kahn et al., 2006; Cooper et al., 2004a; Cooper et al., 2004b; Cooper et al.,. 2004c; Ernst, 2002; Poolton and Barclay, 1998; Song et al., 1997; Souder et al, 1997; Cooper and Kleinschmidt, 1995; Montoya-Weiss and Calantone, 1994), the model suggests that product advantage, marketing skills, company skills, project leader skills, cross-functional integration, NPD teams’ organization method and NPD process proficiency are factors associated with project success, influencing the performance of new products.

In the following sections, we explore the components of our model and we make hypotheses about them. Specifically, we discuss several unique characteristics of SMEs as compared to larger firms carry special significance for NPD management.

2.1 Product advantage

Product advantage refers to a product’s superiority relative to other products on dimensions such as quality, benefit and function (Calantone et al., 2006). It is one of the most frequently reported NPD factors (Montoya-Weiss and Calantone, 1994). Many authors (Cooper and Kleinschmidt, 1995; Poolton and Barclay, 1998; Yap and Souder, 1994) also identify product characteristics that lead them to success. In this article, product advantages such as superior technical performance and low cost.

Product concept clarity based upon a company’s strategy is more important to SMEs than to larger firms because suffer as a result of poor or misguided strategies (Allocca and Kessler, 2006). Project synergy means the degree of fit between the project and the company’s strategies. This factor has been found to correlate with NPD project success (Song and Noh, 2006; Cooper and Kleinschmidt, 1995).

The following hypothesis can be derived from product advantage factor:

H1. Product advantage is related positively to new product success in Brazilian SMEs in the medical device industry.

2.2 Marketing Skills

Marketing skills include aspects such as company’s capacity to assess the new product market potential, to understand the target-market needs and to translate that information into product specifications. A strong market orientation is a critical success factor for new product success (Cooper and Kleinschmidt, 1995; Song et al., 1997; Langerak et al., 2004). Uncontrollable market characteristics also influence new product success (Souder et al, 1997; Ernst, 2002; Langerak et al., 2004), but the company can be kept aware about these conditions if it has marketing skills (Yap and Souder, 1994).

Marketing skills would enable a company to anticipate changing market conditions and respond to market requirements. Nevertheless, SMEs tend to have less marketing resources and do less market research (Ghobadian and Gallear, 1996; Ledwith and O’Dwyer, 2009).

The following hypothesis can be derived from this factor:

H2. The company’s marketing skills are related positively to new product success in Brazilian SMEs in the medical device industry.

2.3 Company Skills

Company skills have been associated to NPD success (Cooper and Kleinschimidt, 1987; Song et al., 1997; Song and Noh, 2006). They are distinctive capabilities of personnel or organizational functions that increase the NPD performance. They are often significant areas of weakness within small technology-based companies, where entrepreneurs tend to emphasize the technological side of their business and neglect other company skills (Berry and Taggart, 1998).

The following hypothesis can be derived from this factor:

H3. The company skills are related positively to new product success in Brazilian SMEs in the medical device industry.

2.4 Project Leader Skills

One of the most important factors that affect NPD performance is the project leader (Brown and Eisenhardt, 1995). The project leader facilitates communication between the project team and senior management. He also holds the responsibility of keeping the team members motivated and focused in their work (Thieme et al., 2003; Brown and Eisenhardt 1995).

The technical, managerial and personal skills of the project leader affect the success of the project. Power, vision, and management skills are posited as the central characteristics of the project leader (Brown and Eisenhardt 1995) who should also have enough authority delegated by top management to lead the new product project towards success.

The following hypothesis can be derived from this factor:

H4. The leadership style and the skills of the project leader are related positively to new product success in Brazilian SMEs in the medical device industry.

2.5 Cross-Functional Integration

Organizational integration and its impact on product market success have also been investigated by researchers (Sherman et al., 2005; Cooper et al., 2004b; Souder and Song, 1998; Grifin, 1997; Yap and Souder, 1994). Thieme et al. (2003) indicate that companies can improve cross-functional integration and planning through project management practices.

SMEs tend to be more flexible. This characteristic promotes less bureaucratization and more functional integration. Also, SMEs may be able to work more efficiently with an organic mentality because of their rapid internal communications, shorter decision chains and fast reaction to requests for changes to product (Allocca and Kessler, 2006).

Top management needs to provide leadership in NPD. It holds the responsibility for promoting a supportive climate, encouraging new ideas and supporting the functional integration in NPD (Cooper et al., 2004a; Song and Parry, 1996). According to Ernst (2002), the role and commitment of top management in NPD performance is not yet fully understood.

Based on these characteristics the following hypotheses are presented:

H5. Top management commitment is related positively to new product success in Brazilian SMEs in the medical device industry.

H6. Integration among functional departments is related positively to new product success in Brazilian SMEs in the medical device industry.

2.6 NPD Teams’ Organization Method

The NPD project can be organized in a number of ways that range from the organization of the project itself to the functional organization. The benefits of adopting a more organic structure have been widely propagated (Larson and Gobelli, 1988). Other studies (Lee et al., 2000, Yap and Souder 1994) have indicated a contingent perspective: a functional-based form of structure is effective for routine and non-radical projects while an organic structure is appropriate for more unusual and radical projects.

The following hypothesis can be derived from this factor:

H7. The use of an organic structure is related positively to new product success in Brazilian SMEs in the medical device industry.

2.7 NPD Process Proficiency

Proficiency refers to the quality of execution of the activities at each stage of the NPD process. Researches have shown that proficiency in development activities brings positive impacts in new product performance (Cooper et al., 2004c; Poolton and Barcklay, 1998; Brown and Eisenhardt, 1995; Clark and Fujimoto, 1991; Cooper and Kleinschmidt, 1987).

According to Cooper et al. (2004c) quality of execution is critical to NPD success across the entire range of activities from idea generation to post launch review. Some authors, however, highlight the importance of pre-development activities (Kahn et al., 2006; Ernst, 2002).

The following hypothesis can be derived from this factor:

H8. The high level of proficiency in NPD activities is related positively to new product success in Brazilian SMEs in the medical device industry.

3. Research Methods

3.1 Sample of companies and projects

Brazilian medical device industry is comprised of 374 companies, including manufacturers, importers and device retailers for dental care, laboratories, radiology and medical services (ABIMO, 2010). Based on criteria such as size (small companies with less than 100 employees and mid-sized companies with 100 to 500 employees), operation segment (device manufacturers) and the existence of active NPD, a total of 52 companies in the State of São Paulo fit the desired profile. From this number, 30 SMEs agreed to participate. The study reported is small and should be considered exploratory in this field in Brazil as there has been no previous examination before.

A contact via e-mail or phone was made to confirm that the selected companies fit the criteria adopted: small or medium companies, which had new product development activity and had completed projects and launched new products in the last five years. The researchers interviewed face to face the person responsible for the projects under analysis, usually the project leader. The objective was to examine two new product projects in each company, one being a success and the other a failure. All the answers were supposed to be grounded on the history, facts and situations experienced at the time of the project execution, so the interviewees were screened for knowledge and responsibility of the project at that time.

All the answers were supposed to be grounded on the history, facts and situations experienced at the time of the project execution, so the interviewees were screened for knowledge and responsibility of the project at that time. Taking into consideration the retrospective nature of the study, the products with a development history more than five years old as well as those in which the key personnel had left the company were excluded, in order to increase the validity of the data to be collected.

The adherence to such criteria resulted in a sample of 30 companies and 49 new product projects, out of which 30 were considered as successful products and 19 failures. The classification as successful or failure was taken by comparing the product performance in relation to the company’s expectation previous to the launching of the product. In cases where performance equaled or surpassed expectations they were classified as successful. The failures projects corresponded to products with performance below expectations.

3.2 Research Instrument

The questionnaire used for data collection was structured to identify the practices adopted during the execution of projects of new devices. It was tested in four companies before being employed in the survey, to ensure the clear understanding of the terms and contents of the questions and that the scales adopted were appropriate.

In this research eight constructs were used to describe possible factors affecting project success. Each construct is comprised by a set of individual variables (factors) identified and defined in the bibliographical review. Construct reliabilities (Cronbach`s alpha) were calculated and exceeded 0.70, which is considered acceptable.

The individual variables were presented in the questionnaire in the form of statements about the existence of a given practice and the interviewees expressed their perception about the degree in which the practice adopted in the project agreed with the statement. The classification of a new product project in either success or failure followed a 5 points Likert scale. Products given 1 or 2 points (well below expectations or below expectations) were classified as failure, while those reaching 3 (as expected), 4 (above expectations) or 5 (well above expectations) were taken as successful projects.

3.3 Statistical analysis

In quantitative survey utilizing qualitative variables measured in Likert scale, it is recommended to use statistical techniques that will provide the correlation degree between dependent and independent variables, the significance analysis of the observed correlation coefficients (p test), as well as the Main Components Analysis (Hair and Anderson, 1998).

In order to measure the correlation between each individual variable and outcome of the product, the Spearman correlation coefficient, which indicates the dependency level between two ordinal variables, was calculated. Coefficients greater than 0.50 were considered strong positive correlation, while those between 0.30 and 0.49 were considered as moderate positive correlation. Below 0.30 there is evidence of weak statistical correlation or no dependency between the variable and the outcome of a new product.

Confidence level tests (p-value) were calculated to observe the degree of such relations. Correlations which had p-values greater than 95% were considered positive, while values below 95% confidence level were considered to have no correlation. The existence of significant differences between the answers of successful and failed projects was calculated using the Mann-Whitney test. The levels of significance for the differences between averages were also calculated.

The relevance of each individual variable was defined by the existence of significant differences in the Mann-Whitney test, by the analysis of Spearman correlation coefficient and by the level of significance of the correlation (p≤0.05).

The individual variables were then reduced by Factor Analysis, that is: the multi-item construct (main component) fitted into one factor which explained a percentage of the total variance of this construct. The correlation between the main components and the outcome of new products was calculated. From the statistical procedures adopted and the interpretation of the results, it was possible to identify a set of variables (practices) that affect the success of new products in these companies.

4. Findings

4.1 Analysis of individual variables and constructs

Table 1 shows the statistically significant results from the statistical tests described in the previous section.

Table 1: Individual variable results

Individual variable results |

Means |

Spearman Test |

|

|

Failure |

Success |

Correlation |

I - Product Advantage |

|

|

|

Technical performance superior to competitors |

2.71 |

3.93** |

0.46* |

Cost advantage |

3.18 |

3.83 |

0.28 |

Product similar to competitors |

3.13 |

2.97 |

0.11 |

Connection between company’s competitive and product strategies |

3.29 |

4.21* |

0.44* |

II – Marketing Skills |

|

|

|

Synergy between markets and the new product |

3.28 |

3.79 |

0.24 |

Rate of growth of market |

3.39 |

4.00* |

0.35 |

Good research of market potential |

2.65 |

3.82** |

0.45* |

Consumers expectancy in relation to new product |

2.89 |

4.31** |

0.44* |

Capability to translate market needs into product specifications |

2.33 |

4.18** |

0.61** |

IV - Company Skills |

|

|

|

Company had the necessary technical capability |

3.83 |

4.31 |

0.20 |

Technical capability in RandD and product development |

3.78 |

4.17 |

0.18 |

Technical capability of commercial area |

3.18 |

3.72 |

0.06 |

Technical capability of manufacturing area |

3.39 |

3.83 |

0.05 |

Technical capability of technical assistance area |

3.72 |

3.66 |

-0.11 |

V - Project Leader Skills |

|

|

|

Technical capability relevant to the project |

4.06 |

4.41 |

0.29* |

Interpersonal relationship capability |

3.67 |

4.17 |

0.35* |

Managerial capability needed in the project |

3.22 |

3.93* |

0.29* |

Capability to motivate development team. |

3.11 |

4.31** |

0.47** |

Decision making authority of leader |

4.11 |

4.14 |

0.10 |

Leadership style adopted facilitates (communication and conflict resolution) |

3.44 |

4.17* |

0.35* |

Participation of development team members in decisions concerning the project |

3.67 |

4.00 |

0.10 |

Capability to motivate development team |

3.50 |

4.34* |

0.32* |

VI – Cross-functional integration |

|

|

|

Top administration involvement and support |

3.67 |

4.45 |

0.33* |

Connection of marketing and R&D |

3.06 |

3.83* |

0.30* |

Connection of manufacturing and R&D |

3.56 |

4.14 |

0.16 |

Participation of varied areas in generation and screening of ideas |

2.06 |

3.48** |

0.54** |

Participation of varied areas in feasibility analysis |

2.06 |

3.14** |

0.27 |

Participation of varied areas in product development |

3.17 |

3.72 |

0.18 |

Participation of varied areas in prototype building |

3.28 |

3.55 |

0.03 |

Participation of varied areas in product and market testing |

2.83 |

3.72* |

0.27 |

Participation of varied areas in commercial launching |

2.65 |

2.90 |

0.09 |

VII - NPD teams’ organization method |

|

|

|

Functional structure |

3.71 |

2.61* |

-0.15 |

Matricial structure |

1.53 |

2.11 |

0.10 |

Project based structure |

1.75 |

2.07 |

0.06 |

VIII - NPD Process Proficiency |

|

|

|

Generation and screening of ideas |

3.61 |

4.34** |

0.51** |

Technical and economical feasibility analysis |

3.06 |

3.97** |

0.40* |

Product development |

3.72 |

4.38** |

0.41* |

Prototype building |

3.72 |

4.21 |

0.25 |

Market testing |

3.17 |

3.97* |

0.40 |

New product launching |

3.12 |

3.9*3 |

0.38 |

Preparation and follow-up of documents and reports for product homologation |

2.80 |

3.71* |

0.26 |

a Mann-Whitney significance test: **p < 0.01; *p < 0.05

b Correlation with successful projects: **p < 0.01 **p < 0.05

The Product Advantage construct contains four statements addressing different product positioning strategies and the fit between the project and the strategy of the companies. The average ratings assigned to successful products were statistically greater than the average ratings assigned to failed products for two factors that show, also, positive correlations with new product success: technical performance superior to competitors (r = 0.46) and connection between the company’s competitive strategies and product strategies (r = 0.44).

The Marketing Skills construct combines five individual variables addressing possible characteristics of the market into which a new product is introduced and the company’s marketing skills. The factors indicate that the capability of the company to gather information about the market, analyze its potential and translate the needs of the clients into product specifications are activities that contribute to the success of a new product. Another critical success factor observed was the existence of an expectation of the clients in relation to the new product. These results indicate that Brazilian managers, in this industry, should put more emphasis on the market-driven process.

The Project Leader Skills construct is comprised of eight individual variables addressing project leader skill, leadership style and project team involvement. For four statements the average ratings assigned to successful products were statistically greater than the average ratings assigned to failed products. The statements that had positive correlations with new product success are: capability to motivate development team (r = 0.47), leadership style (r = 0.35), the motivation of team (r = 0.32) and managerial capability of the leader project (r = 0.29).

The Cross-functional integration construct is comprised of nine individual variables addressing the degree of integration of the functional areas and top management in the project. The variables that showed positive correlation with new product success and significant difference in the average ratings are the integration between Marketing and R&D (r = 0.30) and the participation of functional areas during generation and screening of ideas (r = 0.54). The findings suggest that higher project performance is demonstrated when there is integration between marketing and R&D, during early stages of the project.

The findings indicate that top management support has an impact of little significance on NPD performance. This correlation has a 0.33 rating, which indicates a moderate correlation; however the average ratings assigned to successful and failed products were close together.

Seven individual variables form the NPD Process Proficiency construct. The individual variables that showed significant correlation with NPD success were: generation and screening of ideas (r = 0.51); technical and economic feasibility analysis (r = 0.40) and product development (r = 0.41). The results reinforce the need for greater efficiency in NPD activities, mainly in the pre-development phase (generating and selecting ideas, concept formulation and feasibility analysis), since they were shown to be critical for success.

The contribution of the individual variables of the Company Skills and NPD teams’ organization method was not statistically significant. As regards Company Skills, the successful projects, as well as the failed ones, relied on the same skills and resources of the personnel from the departments involved. In this case, the failure can be explained by reasons other than lack of technical capacity. As the companies under study are small and medium, it is possible that the capabilities of the project leader act as a substitute for the skills of the company.

The models functional organization, matrix or per project approaches practically did not influence the success of the products developed. This is due, possibly, to the fact that satisfactory levels of communications and collaboration among the different areas are facilitated by the size of the companies.

Each construct illustrated in Table 2 shows the reduction of the individual variables by the multivariate analysis technique. It also shows the correlation between each construct and new product success.

Table 2: Construct level results

|

Correlation a |

Eigenvalue |

Explained Variance b |

NPD Process Proficiency |

0.61** |

2.94 |

42% |

Marketing Skills |

0.59** |

2.21 |

44% |

Cross-functional Integration |

0,53** |

2.70 |

27% |

Project Leader Skills |

0,48** |

4.14 |

52% |

Product Advantage |

0.44* |

1.91 |

48% |

Company Skills |

0.14 |

2.46 |

49% |

NPD teams’ organization method |

0.09 |

1.52 |

51% |

a Correlation with successful projects: **p < 0.01, *p < 0.05.

b

total variance of construct explained by the variables that form this construct.

In our sample the success of new products is dependent, mostly, on organizational characteristics of the company, such as Proficiency in NPD and Marketing skills. Successful projects have market research carefully conducted and user’s needs translated adequately to product specifications, which requires that emphasis be given to the activities preparatory to development. Personnel of different functional areas should participate in this stage, which must be performed with the best possible quality. It should be noted the coherence of results in Tables 1 and 2.

4.2 Hypotheses testing

We will use the results shown in Tables 1 and 2 to accept or reject the hypotheses presented in section two. According Table 3, five hypotheses were supported by correlation indexes that exceed 0.4 and confidence level (p-value) of p<0.05.

Table 3: Hypotheses results

Hypothesys |

Construct |

Correlation a |

Conclusion |

H1 |

Product Advantage |

0.44* (Table 2) |

Confirmed |

H2 |

Marketing Skills |

0.59** (Table 2) |

Confirmed |

H3 |

Company Skills |

0.05 (Table 2) |

Not confirmed |

H4 |

Project Leader Skills |

0.48** (Table 2) |

Confirmed |

H5 |

Top Management Support |

0.33* (Table 1) |

Not confirmed |

H6 |

Cross-functional Integration |

0.53** (Table 2) |

Confirmed |

H7 |

NPD teams’ organization method |

0.09 (Table 2) |

Not confirmed |

H8 |

NPD Process Proficiency |

0.61** (Table 2) |

Confirmed |

a Correlation with successful projects: **p < 0.01, *p < 0.05

Hypothesis H1 was confirmed. Therefore, Product Advantage is different for successful and failed projects. With regard to product advantage, the study confirmed that projects that present technical superiority and that are coherent with the existing portfolio of products of the company have greater probability of success. Perhaps SMEs, as a result of their size and limited resources, are forced to choose known market niches and less-complex strategies, reinforced the importance of this factor.

Our data support Hypothesis H2. We found that successful and failed projects differ in terms of marketing skills, mainly the ability to predict market trends and the ability to translate user’s needs in product characteristics. This is supported by Blankson et al. (2006), who found that a strong market orientation may provide sources of competitive advantage for small firms.

We also found that H3 and H5 are not confirmed. Successful and failed projects in our sample do not differ in terms of company skills and top management support. In general, SMEs don’t take several projects simultaneously. Perhaps, this situation leads top management involvement (normally, the owners) and company skills to be the same in the studied projects. SMEs cannot afford the cost associated with lack of focus and direction, poor management and inadequate support.

H4 predicted that successful and failed projects would differ in terms of the skills of the project leader and leadership style adopted. Our empirical data provides support for this hypothesis (p-value < 0.01). When project members are capable and motivated, perhaps strong technical leadership is not as important, but managerial and interpersonal skills are needed.

Our data support hypothesis H6. The integration of Marketing and R&D personnel is fundamental during the pre-development stage. The influence of Marketing in R&D was, again, noticed. Owing to a closer contact with clients Marketing takes a great responsibility in identifying needs, suggesting new product ideas and approving a project either on its own or as part of a multi-functional team.

We did not find any significant relationship between a more organic organizational structure and new product success. The successful utilization of cross-functional teams depends upon the presence of strong management guidance that may be lacking in many SMEs, and may also be a luxury that SMEs can ill afford because of their limited resources. Thus, we must not confirm H7.

Our empirical results confirmed that NPD Process Proficiency, mainly in the early stages of the product development process, was relatively more important in discriminating between success and failure, thus H8 is confirmed.

5. Discussion and Conclusion

5.1 Theoretical Implications

This paper brings theoretical contributions for the area of NPD management. In the first place the paper identifies critical success factors in Brazilian SMEs in the medical device industry, allowing a broad understanding of what leads the project of new medical devices to success. It also increases understanding of the unique attributes possessed by SMEs compared to large firms. The results of the paper answer the need for guidance in making NDP better structured, formalized and controlled in SMEs of technological and operational profile similar to those studied

Second, our conceptual model incorporates a set of factors deemed critical for NPD success. Some of them, analyzed in section 4, were statistically confirmed and they deserve special attention from researchers and managers. The results of this study will assist companies in adopting an evidence based approach to select products to develop and to improve their NPD process.

5. 2 Management Implications

This study highlights critical areas in which the management concerned with strengthening NPD in the industry researched should focus, in particular the findings on Product Advantage, Marketing Skills, Project Leader Skills, Cross-functional Integration and NPD Process Proficiency. The first management point is emphasis on the market and marketing skills. The capability to understand the market turns to be essential in the pre-development stage as several factors of success, as confirmed by the field research, are related to good execution of the activities of market evaluation, generation and analysis of ideas and development of the concept of a new product.

Involving the end user or customer in NPD is important to ensure that the product answers real needs and to increase the likelihood that it will be a market success. In the medical device industry the users can be doctors, nurses, healthcare professionals, or the patients themselves. This leads to the responsibility of SME commercial departments to transfer market information to technical departments to create new products that have technical superiority.

The second point of interest for management disclosed by the research is the necessity for cross-functional integration. The use of multifunctional structures (matrix and project structure) has been adopted by companies as an alternative to surpass barriers created by functional specialization. However, the findings assessed do not indicate significant differences among the organizational structures.

Organic characteristics were perceived in NPD management due to the small size of the companies. This can be evidenced in behaviours such as the emphasis in oral communication, partial adoption of informal norms and procedures, visual control mechanisms, and a natural integration among those involved in NPD.

Our study found that the level of information flow and contact between the technical and commercial areas were strongly correlated to new product success. Cross-functional interface plays an important role in new product success. Thus, integration must be encouraged by top management, especially in pre-development activities.

The third point of interest for management refers to the proficiency of NPD activities. When examining the results of Tables 1 and 2, we can observe which project activities should receive special attention in NPD activities by the companies. We found that the earlier stages of the NPD process have a greater effect on new product success. The fourth point of interest for management is the role of the project leadership. Our findings reinforce the importance of the presence of a leader with managerial capabilities and strong drive for team work, a profile that should be sought by companies when selecting leaders for new product projects.

5.3 Limitations and Suggestions for Future Research

New Product Development is a complex process and any research in this area has limitations. One of the limitations in this study is the fact that it was carried out with a small sample of SMEs medical device producers.

Another limitation is a consequence of the complexity of the theme under study. Some practices relating to PDP management were not included in the scope of the proposed conceptual model, such as gates-review practices, financial evaluation of the project along the process of development, technological predictability, and so on. Future works can replicate the methodology adopted in other sectors, so that knowledge of NPD management in SMEs can be better explored.

6. References

ABIMO (Brazilian Association for Medical, Dental and Hospital Device Industry), 2010. URL http://www.abimo.org.br. [accessed on 3 May 2010]

Allocca, M. A. and Kessler, E. H. (2006) Innovation Speed in Small and Medium-Sized Enterprises. Creativity and Innovation Management, 15: 279–295.

Berry, M.M.J. and Taggart, J.H. (1998) Combining technology and corporate strategy in small high tech firms. Research Policy, 26: 883-895.

Blankson, C., Motwanti, J.G., and Levenburg, N.M. (2006) Understanding the Patterns of Market Orientation among Small Businesses. Marketing Intelligence and Planning, 24: 572–90.

Brown, S. L., and Eisenhardt, K. M. (1995) Product development: past research, present findings, and future-directions. Academy of Management Review 20: 343-378.

Calantone, R.J.; Chan, K and. Cui, A.S. (2006) Decomposing Product Innovativeness and Its Effects on New Product Success. Journal of Product Innovation Management, 23, 408–421.

Clark, K. B., and Fujimoto, T. (1991). Product development performance: strategy, organization and management in the world auto industry. HBS Press : Boston, USA.

Cooper, R. G., Edgett, S. J., and Kleinschmidt, E. J. (2004a). Benchmarking best NPD practices-I. Research Technology Management, 47: 31-43.

Cooper, R. G., Edgett, S. J., and Kleinschmidt, E. J. (2004b). Benchmarking best NPD practices-II. Research Technology Management, 47: 50-59.

Cooper, R. G., Edgett, S. J., and Kleinschmidt, E. J. (2004c). Benchmarking best NPD practices-III. Research Technology Management, 47: 43-55.

Cooper, R.G. and Kleinschmidt, E. J. (1987). What makes a new product a winner: success factors at project level. The Journal of Product Innovation Management, 4: 175-189.

Cooper, R.G. and Kleinschmidt, E. J. (1995). Benchmarking the firm’s critical success factors in New Product Development. The Journal of Product Innovation Management, 12: 374-391.

Ernst, H. (2002). Success factors of new product development: a review of the empirical literature. International Journal of Management Review, 4: 1-40.

Freel, M. (2000). Barriers to Product Innovation in Small Manufacturing Firms. International small Business Journal, 18: 60–79.

Ghobadian, A. and Gallear, D. (1996) Total quality management in SMEs, Omega, 24: 83–106.

Grifin, A. (1997). PDMA Research on new product development practices: Updating trends and benchmarking best practices. Journal of Product Innovation Management, 14: 429-458.

Hair, J.F., Anderson, R.E., Tatham, R.L.and Black, W.C. (1998). Multivariate data analysis (5th ed.). New Jersey: Prentice-Hall.

Kahn, K.B, Barczak, G., and Moss, R. (2006). Perspective: Establishing an NPD best practices Framework.. Journal of Product Innovation Management, 23: 106-116.

Langerak, F., Hultink, E. J. and Robben, H. S. J. (2004). The impact of market orientation, product advantage, and launch proficiency on new product performance and organizational performance, Journal of Product Innovation Management, 21: 79-94.

Larson, E. W., and Gobelli, D. H. (1988). Organizing for product development projects. Journal of Product Innovation Management, 5: 180–190.

Ledwith, A. and O’Dwyer, M. (2009) Market Orientation, NPD Performance, and Organizational Performance in Small Firms. Journal of Product Innovation Management, 26: 652–661.

Lee, J.; Lee, J.; Souder, W. E. (2000). Differences of organizational characteristics in new product development cross-cultural comparison of Korea and US. Technovation, 20: 497-508.

Mahemba, C. M. and Bruijn, E. J. D. (2003), Innovation Activities by Small and Medium-sized Manufacturing Enterprises in Tanzania. Creativity and Innovation Management, 12: 162–173.

Maidique, M A. and Zirger, B. J. (1987). A study of success and failure in product innovation: the case of the U.S. electronics industry. IEEE Transactions on Engineering Management, 34 : 192–203.

Montoya-Weiss, M., and Calantone, R. (1994). Determinants of new product performance: a review and meta-analysis. Journal of Product Innovation Management ,11 : 397-417.

Poolton, J., and Barcklay, I. (1998). New Product Development From Past Research to Future Application. Industrial Marketing Management, 27: 197-212.

Salavou, H. and Lioukas, S. (2003) Radical Product Innovations in SMEs: The Dominance of Entrepreneurial Orientation. Creativity and Innovation Management, 12: 94–108.

Sherman, J. D., Berkowitz, D., and Souder, W. E. (2005). New Product Development Performance and the Interaction of Cross-Functional Integration and Knowledge Management. Journal of Product Innovation Management, 22: 399-411.

Song, X. M. and Noh, J. (2006). Best new product development and management practices in the Korean high-tech industry. Industrial Marketing Management, 35: 262–278.

Song, X. M., and Parry, M. E. (1996). What separates Japanese new product winners from losers. Journal of Product Innovation Management, 13: 422−439.

Song, X. M., Souder, W. and Dyer, B. (1997). A causal model for studying the impact of skills, synergy, and design sensitivity on new product performance. Journal of Product Innovation Management, 14: 88–101.

Souder, W. E., and Song, X. M. (1998). Analyses of US and Japanese management processes associated with new product success and failure in high and low familiarity markets. Journal of Product Innovation Management, 15: 208–223.

Souder, W. E., Buisson, D., and Garret, T. (1997). Success through customer-driven new product development: a comparison of US and New Zealand small entrepreneurial high technology firms. Journal of Product Innovation Management, 14 : 459-472.

Souza, J.H., Cappa, J. A indústria de produtos hospitalares e a infra-estrutura de apoio noi interior do estado de São Paulo. Revista Espacios, 29, n2, p.19

Thieme, R. J., Song, X. M., and Shin, G. C. (2003). Project management characteristics and new product survival. Journal of Product Innovation Management, 20: 104-119.

Yap, C.M., and Souder, W.E. (1994). Factors Influencing New Product Success and Failure in Small Entrepreneurial High-Technology Electronic Firms. Journal of Product Innovation Management, 11: 418-432.