1. Introduction

The environmental issue has become challenging to business organizations in the past years. Consequently, its operations are subject to increasing pressures and analysis of various stakeholders within and outside the organization, such as government agencies, workers, and non-profit groups. These challenges and pressures cause them to seriously consider environmental impacts when making their businesses.

This concern with the environment causes the emergence of a growing customer demand for products and companies that are more environmentally friendly. The environmental acceptability of a product is the hallmark of the new century, and issues such as ecodesign (Ryan, Hosken and Greene, 1992; Lofthouse, 2004) are part of organizations strategies and become part of the product design from the design to the selection of materials, even at the pre-project stage.

Multiple senses of the term ecodesign (or DfE – Design for Environment) can be found in the literature. Karlsson and Luttropp (2006), for example, argue that ecodesign focuses on the integration of environmental considerations in product development, and eco-design tools should be made available to designers during the product development process. In the words of Bereketli, Genevois and Ulukan (2009) the key issue for the success of an ecodesign product is not just to meet environmental goals, such as energy conservation and resources and reduced environmental impact but also to take into account cost effectiveness, market demand, and multi-functionality requirements.

Ecodesign ensures that a product is derived from the conscious use of energy, water and raw material. This practice is essential for those organizations that recognize environmental responsibility as vital to long-term success. For it provides advantages such as lower costs and less waste besides generating product innovation and attracting new customers. It can be said that ecodesign activities include (Sarkis, 1998; Beamon, 1999; Lin, Jones and Hsieh, 2001; Zsidisin and Siferd, 2001; Apo, 2004; Eltayeb, Zailani and Ramayah, 2011):

- Design for the reduction or elimination of environmentally hazardous material - such as lead, mercury, cadmium and chromium;

- Design for reuse – it facilitates the reuse of a product or part of it, with or without minimal treatment of the product used;

- Design for recycling – it facilitates disassembly of the product and waste, separation of the parts in accordance to the material, and material reprocessing;

- Design for remanufacture – it facilitates repair, rework and remodeling activities designed to return a new product and improve it to a new condition;

- Design for resource efficiency – it includes energy and material consumption reduction of a product during use, besides promoting the use of renewable resources and energy.

Considering that ecodesign is a recent subject for the organizations, the aim of this paper is to present the results of a structured literature review (Seuring and Muller, 2012), through a selection of article sampling, to perform bibliometric analysis on the topic as well as provide a conceptual framework for future research.

2. Research methodology

A literature review is a systematic, explicit, and reproducible design for identifying, evaluating, and interpreting the existing body of recorded documents (Fink, 1998). Literature reviews usually aim at two objectives: first, summarize existing research, identifying patterns, themes and issues and; second, this helps identify the conceptual content of the field (Meredith, 1993) can contribute to the theory development (Harland et al., 2006; Seuring and Muller, 2008). From a methodological point of view, literature review can be understood as content analysis, where the quantitative and qualitative aspects are combined to assess structural (descriptive) well as content criteria. A process model proposed by Mayring (2003) contains four steps:

- Material collection: the material to be collected is defined and delimitated. Furthermore, the unit of analysis is defined.

- Descriptive analysis: formal aspects of the material are assessed, for example, the number of publications per year, thus, providing the background for subsequent theoretical analysis.

- Category selection: Structural dimensions and related analytic categories are selected, that are to be applied to the collected material. Structural dimensions form the main topics of analysis, which are constituted by single analytic categories.

- Material evaluation: the material is analyzed according to the structural dimensions. This should allow identification of relevant issues and interpretation of results.

In this context, this paper has the character of a literature review and can be understood as content analysis, where quantitative and qualitative aspects are used. Thus, an analytical review is required for the contribution systematic evaluation on a particular literature topic. Generally, the review process consists in three parts: data collection, data analysis and synthesis (or reporting). Scientific rigor in conducting each of these steps is critical to an analysis of their quality. Data collection can be done in different ways. As an example, using the existing knowledge in literature to select articles and search various databases using keywords.

Once the items are selected for review, data analysis can proceed in different ways, depending on the review objectives (Tranfield, Denyer and Smart, 2003; Crossan and Apaydin, 2010). A review to consolidate the results of several empirical studies may depend on either qualitative or quantitative results analysis. Data summary is the main product of the research since it produces new knowledge based on complete data collection. Figure 1 shows the methodology using in this paper.

Figure 1 – Steps followed in the research paper

Source: Authors’ elaboration.

For this paper, a three-stage procedure was followed: Planning, Implementation and Reporting. During the Planning stage, the following procedures were performed:

- Defining research purpose and identification of data sources;

- Delimitation of time interval used (2000-2012);

- Criteria determination for base selection: multidisciplinary, applied social sciences and engineering with access via Portal Capes, and with filters for making exporting data to a bibliographic reference management software possible;

- Base test: they were previously tested with the keyword “root” ecodesign and eco-design to verify their contribution on the subject. The selected bases were: Scopus (http://www.scopus.com/home.url), ScienceDirect (www.sciencedirect.com), Emerald (www.emeraldinsight.com);

- Limitation only to journals as data sources, because these can be considered validated knowledge and are likely to have greater impact.

The second step, Implementation, consists of:

- Conducting searches in selected bases, totaling 523 articles;

- Export to Software bibliographical reference manager Endnote version Web;

- Duplication elimination, where 111 discarded items;

- Affinity analysis, such as: titles, keywords, abstract and content of the articles on the theme, totaling 237 eliminated articles;

- Elimination of paid journals, a total of 43 articles;

- Analysis of a sample resulting from 132 articles, in stage 3.

The third and last stage concerns the Reporting that is the bibliometric analysis of the selected articles sampling. The methodological procedures final result was a sample of 132 articles in which the following aspects were analyzed: authors’ origin, most cited authors, most cited journals, most cited articles (or scientific recognition), and the dimensions of ecodesign from the analysis of keywords and content analysis of the 132 articles. The types of research conducted in these articles were also analyzed, being considered in the used classification (Filippini, 1997; Berto and Nakano, 2000; Gupta, Verma and Victorino, 2006):

- Field Study – presence of field data, especially with qualitative approach, without the research method formal structuring;

- Theoretical/conceptual – conceptual discussions from literature, literature reviews. Conceptual modeling, based on the author’s perceptions and experiences;

- Case Study – depth analysis of one or more objects (cases), using multiple instruments for data collection and interaction between the researcher and the research object;

- Experiment – a study of the causal relationship between two system variables under conditions controlled by the researcher;

- Simulation – presence of computational techniques to simulate the operation of production systems, from mathematical models;

- Modeling – use of mathematical techniques to describe the operation of a system or part of a production system;

- Survey – use of a single data collection instrument, usually a questionnaire, applied to large size samples, using sampling techniques and statistical analysis.

3. Results

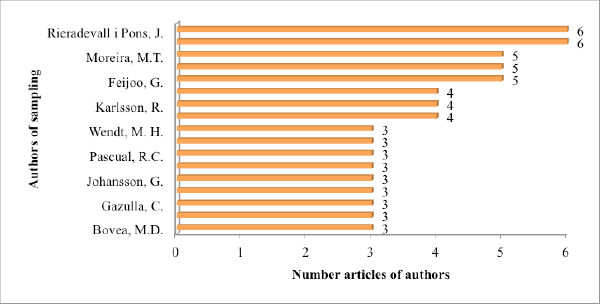

3.1. Most cited authors of the sample

There were 431 authors counted in total, among authorships and co-authorships. Figure 2 highlights authors that contain the largest number of selected sample articles.

The featured author was Rieradevalli Pons, J., appearing in 7 co-authorships, which are: “The ecodesign and planning of sustainable neighbourhoods: the Vallbona case study (Barcelona)”;“Eco-innovation of a wooden based modular social playground: application of LCA and DfE methodologies”; “Eco-innovation of a wooden childhood furniture set: an example of environmental solutions in the wood sector”; “Assessing the global warming potential of wooden products from the furniture sector to improve their ecodesign”; “Using LCA to assess eco-design in the automotive sector: case study of a polyolefinic door panel” and; “Eco-design in innovation driven companies: perception, predictions and the main drivers of integration: the Spanish example”.

Figure 2 – Most cited authors in the sample

Source: Authors’ elaboration.

González-García, S. presented the authorship of 5 articles, which deal with the use of ecodesign in manufacturing furniture and sustainable production of wooden boxes for storing wine bottles, being: “Eco-innovation of a wooden based modular social playground: application of LCA and DfE methodologies”; “Eco-innovation of a wooden childhood furniture set: an example of environmental solutions in the wood sector”; “Assessing the global warming potential of wooden products from the furniture sector to improve their ecodesign”; “Environmental assessment and improvement alternatives of a ventilated wooden wall from LCA and DfE perspective” and; “Combined application of LCA and eco-design for the sustainable production of wood boxes for wine bottles storage”.

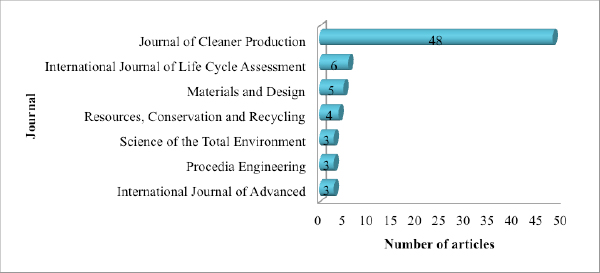

3.2. Most cited journals

Figure 3 shows the most cited journals in the selected article sampling. The objective of this analysis is to identify the main sources of publication on ecodesign and determine which (s) journal (s) has the greatest influence in forming of the content in this area.

Figure 3 – Most cited journals in sampling

Source: Authors’ elaboration.

The journals’ highlight in Figure 3 is Journal of Cleaner Production with a share of 36% (or 48 articles) in the sample of 132 articles. The Journal of Cleaner Production has an interdisciplinary, international focus, and it aims to encourage industrial innovation, new and improved products, and the implementation of new processes, products and cleaner services.

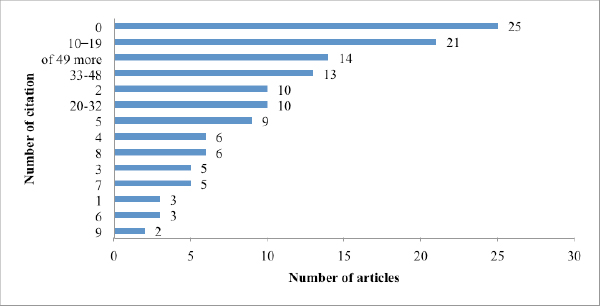

3.3. Most cited articles

Figure 4 shows the citation or scientific acknowledgment number of the sampling articles. For this analysis the number of citation was stratified by categories. Out of the 132 articles, 14 had 51 or more citations, while 25 articles had no citation. To find the citation number, Google Scholar was used on 09/09/2012.

Figure 4 – Citation number of sampling articles

Source: Authors’ elaboration.

The most cited articles were: “Developing sustainable products and services” by Maxwell, D.; Van der Vorst, R., published on Journal of Cleaner Production in 2003 with 151 citations; “Sustainable product-service systems” by Roy, R., published on Futures in 2000 with 121 citations; “EcoDesign and The Ten Golden Rules: generic advice for merging environmental aspects into product development” by Luttropp, C.; Lagerstedt, J., published on Journal of Cleaner Production in 2006 with 110 citations.

3.4. Methodology types

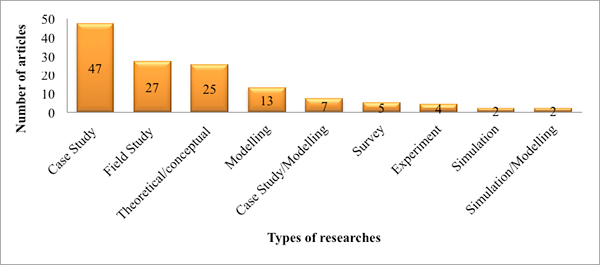

Finally, the types of research present in the article sampling of were analyzed, and the highlights were: 47 case studies and 27 field studies as shown in Figure 5.

Figure 5 – Types of researches in sampling articles

Source: Authors’ elaboration.

In this group, the paper of literature review, the conceptual discussions (with the absence of field data) and secondary data analyses were classified, i.e. obtained from sources other than direct, as well as conceptual modeling. So, as in the case study (Berto and Nakano, 2000) it is important to note that often, because the object of study refers to a single company, it makes the label "Case Study" be used, even if that data collection and organization analysis do not reach the depth required for this type of research.

3.5. Ecodesign dimension: content analysis

By analyzing the keywords and the content of 132 articles, one can classify the dimensions or contexts where ecodesign is (Table 1).

Table 1 – Detected ecodesign dimensions in the sample

Ecodesign Dimension |

Economic and social |

Economic gains; sustainable development; environmental costs; product life cycle cost; waste containment and treatment; technology; sustainability; environmental legislation; environmental policies; social impacts; conscious consumption; productivity natural resources; energy efficiency environmental impact. |

Managerial |

Green marketing; Series ISO14000; reverse logistics; environmental performance; eco-efficiency; material selection; environmental strategy; environmentally conscious design; material composition; ethics; eco-innovation; material and energy reduction; creativity; product extended durability; innovation; functional requirement of the product; eco ideation; environmental benchmarking; product functional aspects; product simplifying; environmental communication; product lifecycle management; recovery; environmental audit; clean technology; material components; product disassembly simplifying; product life cycle assessment; product performance; eco-redesign; reengineering processes; material flow; life-cycle concept; renewable materials use; sustainable solutions; |

|

Environmental |

Cleaner production; ecological gains; toxicity reduction; gas emissions; greenhouse; pollution control; environmental benefits; material extraction; recycling; reuse; environmentally friendly products; industrial ecology; environmental improvement; eco material; natural material reserves; low energy modal transport; material extraction process; eco product. |

Source: Authors’ elaboration.

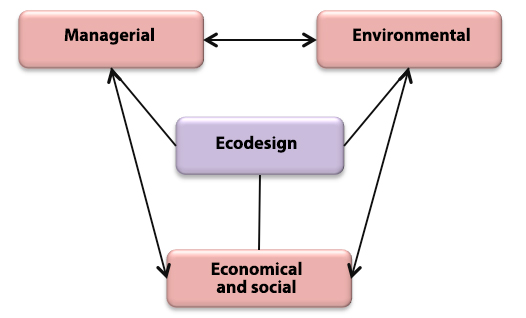

Thus, by means of Table 1 it is possible to establish the ecodesign dimension’s that is show in Figure 6.

Figure 6 – Ecodesign dimensions

Source: Authors’ elaboration.

- The economic and social dimension of ecodesign (sustainable product) implies that products will be evaluated based on whether they meet needs considered important. The basic principle of sustainable development is to meet current needs without harming future generations from meeting their needs. Sustainable development has a broader view of the environment, including also social and political factors that affect the quality of life and environmental preservation. However, the design of sustainable product will not succeed without changes in the system around the products, such as raw material production, taxes, and consumption patterns. The product integrated policy (Bhander, Hauschild and Mcaloone, 2003) is seen as one of many promising initiatives to improve structure around the practice of sustainable product design.

- The environmental dimension implies that one of the main causes of environment pollution and degradation comes from the current production and consumption model. This is based on the concept that the environment is an infinite unlimited resource and energy supplier and it is seen as an unlimited waste receptor (Manahan, 1999). In this waste reduction issue, (Borchard et al., 2008) it is important to highlight the concept of industrial ecology proposed by Jay Forrester, in the 1960s, based on systems theory. The industrial ecology considers that all waste and materials must be continuously recycled within a closed system and only unlimited solar energy would be used in a dissipative.

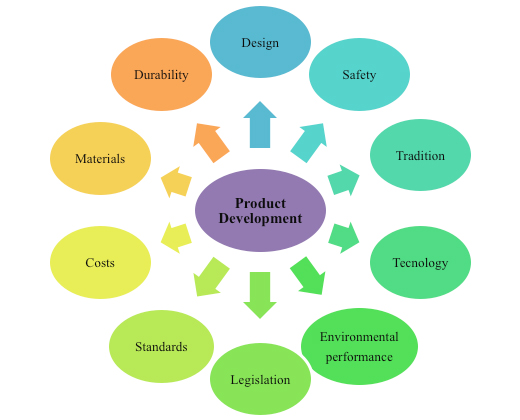

- Finally, in the managerial dimension, there are new techniques that are constantly evolving and seek to incorporate environmental analyses in the early stages of product development (Figure 7 illustrates the complexity of issues in new product development), including the reuse, remanufacturing, recycling and waste treatment. A common feature of these technologies is that they apply a life cycle perspective on the environmental and health impacts from the product or system. The methodology used most (Bhander, Hauschild and Mcaloone, 2003) for this purpose is the evaluation of the product Life Cycle Assessment (LCA). Life Cycle Assessment (LCA) is a technique for assessing environmental aspects and potential impacts associated to a product. LCA methodology comprises a set of different approaches and methods within a general framework. It is a powerful tool for environmental analysis in the development of environmentally superior products.

Figure 7 – Issues affecting product development

Source: Adapted from Bhander, Hauschild e Mcaloone (2003)

However, these products are not favorable in the market place as expected even though they sound environmental more friendly and economical dimension. This situation may be due to that they are focused solely on environmental impact analysis without paying much attention to customer needs and cost considerations (Bereketli, Genevois and Ulukan, 2009). In other words, the key issue for a successful ecodesign product is not only to meet environmental objectives such as resource and energy conservation and environmental burden reduction but also to take into account cost effectiveness, market demand, and multi-functionality requirements.

Therefore, products with ecodesign must allocate limited resources as much as possible, reduce environmental impacts, but without reducing performance. That is, improving environmental impact without compromising on quality, functionality, cost, and appearance of the products. With this research, it was possible to provide the researcher needed knowledge to start a study with ecodesign theme.

4. Conclusions

In the current socioeconomic context, organizations are realizing the importance of using materials and processes that entail less environmental impact, considering that the ecological issue will directly reflect in the cost, once you consider the time spent on operation, material and production energy reduction. Thus, the importance of ecodesign is highlighted for the correct material choice, which causes less damage to the environment.

That is, ecodesign is generally oriented to reduce the depletion of primary and/or other types of environmental impact, providing the following advantages: reducing the number of different materials and selection of the most suitable ones, reducing the environmental impact during the production phase; optimizing the distribution phase; reducing the environmental impact during use; prolonging the useful product life; simplification of the product disassembling; reuse design; recycling design, among others.

This paper aimed to present the results of a structured literature review (through a selection of sampling of articles) and bibliometric analysis on the topic as well as provide a conceptual framework for future research. Therefore, a three-stage procedure was performed, Planning, Implementation and Reporting for building this portfolio. Searches were conducted via Capes periodic portal (in the databases Scopus, ScienceDirect and Emerald), comprising the period 2000-2011.

The advantage of this proposed methodology type in this article is that it can be used to structure any research topic in several areas. A bibliometric analysis provides a guide to researchers, because through it, for example, one can find out which journals or periodicals that publish on the topic you want to paper, recognized authors and scientifically recognized titles.

Some limitations in the research can be highlighted: (i) it only considered articles published in international journals; (ii) research sources such as books, dissertations, conferences annals theses, events were excluded; (iii) only three databases were considered and; (iv) only free access databases via portal Capes were considered.

As recommendations for future study, it is suggested to perform bibliometric analysis of the references of the sample, and thereby compare whether the most cited journals in the sample coincide or not with the references used for this articles, and if the authors cited are present in references. Also, as a suggestion, to highlight the conducting of a field survey in enterprises, to discover what practices and the degree of knowledge there is on ecodesign.

This work, besides contributing to fostering discussions in academic science, also contributes to the business sector. For, ecodesign is extremely important to success in the long term, promotes advantages as lower costs, less waste, raises product innovation and attracts new customers.

References

Apo, 2004. Asian Productivity Organization. Eco-products directory. Tokyo: Asian Productivity Organization; 2004.

Beamon, B.M., 1999. Designing the green supply chain. Logistics Information Management, 12(4): 332-42.

Berto, R.M.V.S., Nakano, D.N., 2000. A produção científica nos anais do Encontro Nacional de Engenharia de Produção: um levantamento de métodos e tipos de pesquisa. Produção, 9(2): 65-76.

Bhander, G. S., Hauschild, M., Mcaloone, T., 2003. Implementing Life Cycle Assessment in Product Development. Environmental Progress, 22(4): 255 ? 267.

Crossan, M.M., Apaydin, M., 2010. A multi-dimensional framework of organizational innovation: a systematic review of the literature. Journal of Management Studies, 47(6): 1154 ? 1191.

Filippini, R., 1997. Operations management research: some reflections on evolution, models and empirical studies in OM. International Journal of Operations and Production Management, 17(7): 655 ?? 70.

Fink A., 1998. Conducting research literature reviews: from paper to the internet. Thousand Oaks: Sage.

gupta, S., Verma, L., Victorino, R., 2006. Empirical Research Published in Production and Operations Management (1992-2005): trends and future research directions. Production and Operations Management, 15(3): 432 ? 448.

Harland, C.M. et al., 2006. Supply management: is it a discipline? International Journal of Operations & Production Management, 26(7): 730 ? 53.

Lin B., Jones, C., Hsieh, C., 2001. Environmental practices and assessment: a process perspective. Industrial Management & Data Systems, 101(2): 71 ? 80.

Manahan, S.E., 1999. Industrial ecology, environmental chemistry and hazardous waste. New York: Lewis Publishers.

Mayring P., 2002. Einführung in die qualitative Sozialforschung – eine Anleitung zum qualitativen Denken. [Introduction to qualitative social research]. Weinheim, Germany: Beltz Verlag.

Meredith J., 1993. Theory building through conceptual methods. International Journal of Operations & Production Management, 13(5): 3 ? 11.

Ryan, C.J., Hosken, M., Greene, D., 1992. EcoDesign: design and the response to the greening of the international market. Design Studies, 13(1): 3 ? 22.

Sarkis J., 1998. Evaluating environmentally conscious business practices. European Journal of Operational Research, 107(1): 159 ? 74.

Seuring, S., Muller, M., 2008. From a literature review to a conceptual framework for sustainable supply chain management. Journal of Cleaner Production, 16(15): 1699 ? 1710.

Tranfield, D., Denyer, D., Smart, P., 2003. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. British Journal of Management, 14, 207 ? 22.

Zsidisin, G.A., Siferd S.P., 2001. Environmental purchasing: a framework for theory development. European Journal of Purchasing & Supply Management, 7(1): 61 ? 73.

FURTHER REFERENCES (table, figure and content analysis)

Aizawa, H., Yoshida, H., Sakai, S.I., 2008. Current results and future perspectives for Japanese recycling of home electrical appliances. Resources, Conservation and Recycling, 52(12): 1399 ? 1410.

Allione, C. et al., 2012. From ecodesign products guidelines to materials guidelines for a sustainable product: qualitative and quantitative multicriteria environmental profile of a material. Energy, 39(1): 90 ? 99.

Almeida, C.M.V.B. et al., 2010. Emergy as a tool for Ecodesign: evaluating materials selection for beverage packages in Brazil. Journal of Cleaner Production, 18(1): 32 ? 43.

Alves, C. et al., 2010. Ecodesign of automotive components making use of natural jute fiber composites. Journal of Cleaner Production, 18(4): 313 ? 327.

Aoe, T., 2007. Eco-efficiency and ecodesign in electrical and electronic products. Journal of Cleaner Production, 15(15): 1406 ? 1414.

Arana-Landin, G., Heras-Saizarbitoria, I., 2011. Paving the way for the ISO 14006 ecodesign standard: an exploratory study in Spanish companies. Journal of Cleaner Production, 19(9-10): 1007-1015.

Ben-Gal, I., Katz, R., Bukchin, Y., 2008. Robust eco-design: a new application for air quality engineering. IIE Transactions (Institute of Industrial Engineers), 40(10): 907 ? 918.

Bereketli, I. et al., 2009. Green product design for mobile phones. World Academy of Science, Engineering and Technology, 58, 213 ? 217.

Bergeå, O. et al., 2006. Education for sustainability as a transformative learning process: a pedagogical experiment in EcoDesign doctoral education. Journal of Cleaner Production, 14(15-16): 1431 ? 1442.

Bernasconi, A., Rossin, D., Armanni, C. 2007. Analysis of the effect of mechanical recycling upon tensile strength of a short glass fibre reinforced polyamide 6,6. Engineering Fracture Mechanics, 74(4): 627 ? 641.

Besseris, J.G., 2012. Eco-design in total environmental quality management: design for environment in milk-products industry. The TQM Journal, 24(1): 47 ? 58.

Birch, A., Hon, K.K.B., Short, T., 2012. Structure and output mechanisms in Design for Environment (DfE) tools. Journal of Cleaner Production, 35, 50 ? 58.

Bocken, N.M.P. et al., 2011. Development of an eco-ideation tool to identify stepwise greenhouse gas emissions reduction options for consumer goods. Journal of Cleaner Production, 19(12): 1279 ? 1287.

Boks, C., 2006. The soft side of ecodesign. Journal of Cleaner Production, 14(15-16): 1346 ? 1356.

Boks, C., Stevels, A., 2003. Theory and practice of environmental benchmarking in a major consumer electronics company. Benchmarking: An International Journal, 10(2): 120 ? 135.

Borchardt, M. et al., 2008. Considerações sobre ecodesign: um estudo de caso na indústria eletrônica automotiva. Ambiente & Sociedade, 11(2): 341 ? 353.

______. et al., 2010. Stiffener redesign: a case of eco-design application in footwear manufacture. Produção, 20(3): 392 ? 403.

Bovea, M.A.D., Vidal, R., 2004. Materials selection for sustainable product design: a case study of wood based furniture eco-design. Materials & Design, 25(2): 111 ? 116.

Bovea, M.A.D., Gallardo, A., 2006. The influence of impact assessment methods on materials selection for eco-design. Materials & Design, 27(3): 209 ? 215.

Bovea, M.A.D., Pérez-Belis, V., 2012. A taxonomy of ecodesign tools for integrating environmental requirements into the product design process. Journal of Cleaner Production, 20(1): 61 ? 71.

Buttol, P. et al., 2012. Integrating services and tools in an ICT platform to support eco-innovation in SMEs. Clean Technologies and Environmental Policy, 14(2): 211 ? 221.

Byggeth, S., Hochschorner, E., 2006. Handling trade-offs in Ecodesign tools for sustainable product development and procurement. Journal of Cleaner Production, 14(15-16): 1420 ? 1430.

Cerdan, C. et al., 2009. Proposal for new quantitative eco-design indicators: a first case study. Journal of Cleaner Production, 17(18): 1638 ? 1643.

Chang, H.-T., Chen, J.L., 2004. The conflict-problem-solving CAD software integrating TRIZ into eco-innovation. Advances in Engineering Software, 35(8-9), 553 ? 566.

Chen, R.-Y., 2009. RFM-based eco-efficiency analysis using Takagi–Sugeno fuzzy and AHP approach. Environmental Impact Assessment Review, 29(3): 157 ? 164.

Chulvi, V.; Vidal, R., 2011. Usefulness of evolution lines in eco-design. Procedia Engineering, 9, 135 ? 144.

Çinar, H., 2005. Eco-design and furniture: environmental impacts of wood-based panels, surface and edge finishes. Forest Products Journal, 55(11): 27 ? 33.

Clay, S., Gibson, D., Ward, J., 2007. Sustainability Victoria: influencing resource use, towards zero waste and sustainable production and consumption. Journal of Cleaner Production, 15(8–9): 782 ? 786.

Collado-Ruiz, D., Ostad-Ahmad-Ghorabi, H., 2010. Influence of environmental information on creativity. Design Studies, 31(5): 479 ? 498.

Czaplicka, K., 2003. Eco-design of non-metallic layer composites with respect to conveyor belts. Materials and Design, 24(2): 111 ? 120.

Deutz, P., Neighbour, G., Mcguire, M., 2010. Integrating sustainable waste management into product design: sustainability as a functional requirement. Sustainable Development, 18(4): 229 ? 239.

Devanathan, S. et al., 2010. Integration of sustainability into early design through the function impact matrix. Journal of Mechanical Design, Transactions of the ASME, 132(8): 0810041 ? 0810048.

Donnelly, K. et al., 2006. Eco-design implemented through a product-based environmental management system. Journal of Cleaner Production, 14(15–16): 1357 ? 1367.

Drack, M., Wimmer, R., Hohensinner, H., 2004. Treeplast Screw - a device for mounting various items to straw bale constructions. Journal of Sustainable Product Design, 4(1 ? 4): 33 ? 41.

Drouineau, M. et al., 2008. Eco-design stakes of electrical steel: dynamic losses sensitivity. Journal of Magnetism and Magnetic Materials, 320(20): 1070 ? 1073.

Eltayeb, T.K., Zailani, S., Ramayah, T., 2011. Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: investigating the outcomes. Resources, Conservation and Recycling, 55(5): 495 ? 506.

Erol, P., Thöming, J., 2005. ECO-design of reuse and recycling networks by multi-objective optimization. Journal of Cleaner Production, 13(15): 1492 ? 1503.

Farreny, R. et al., 2011. The ecodesign and planning of sustainable neighbourhoods: the Vallbona case study (Barcelona). Informes de la Construccion, 63, 115 ? 124.

Favi, C. et al., 2012. Innovative software platform for eco-design of efficient electric motors. Journal of Cleaner Production, 37, 125 ? 134.

Finster, M., Eagan, P., Hussey, D., 2001. Linking industrial ecology with business strategy: creating value for green product design. Journal of Industrial Ecology, 5(3): 107 ? 125.

González-García, S. et al., 2011. Assessing the global warming potential of wooden products from the furniture sector to improve their ecodesign. Science of the Total Environment, 410–411, 16 ? 25.

_______., Combined application of LCA and eco-design for the sustainable production of wood boxes for wine bottles storage. International Journal of Life Cycle Assessment, 16(3): 224 ? 237.

_______., 2012. Eco-innovation of a wooden based modular social playground: application of LCA and DfE methodologies. Journal of Cleaner Production, 27, 21 ? 31.

_______., 2012. Eco-innovation of a wooden childhood furniture set: an example of environmental solutions in the wood sector. Science of the Total Environment, 426, 318 ? 326.

_______., 2012. Environmental assessment and improvement alternatives of a ventilated wooden wall from LCA and DfE perspective. International Journal of Life Cycle Assessment, 17(4): 432 ? 443.

Gottberg, A. et al., 2006. Producer responsibility, waste minimisation and the WEEE Directive: Case studies in eco-design from the European lighting sector. Science of the Total Environment, 359(1 ? 3): 38 ? 56.

Grote, C.A. et al., 2007. An approach to the EuP Directive and the application of the economic eco-design for complex products. International Journal of Production Research, 45(18 ? 19): 4099 ? 4117.

Halada, K., Aizawa, T., Mabuchi, M., 2002. New step of ecomaterial to break through the barrier between ecomaterial-selection and eco-design. Materials Transactions, 43(3): 397 ? 405.

Hauschild, M., Jeswiet, J., Alting, L., 2005. From Life Cycle Assessment to sustainable production: status and perspectives. CIRP Annals - Manufacturing Technology, 54(2): 1 ? 21.

Herva, M. et al., 2012. Application of fuzzy logic for the integration of environmental criteria in ecodesign. Expert Systems with Applications, 39(4): 4427 ? 4431.

Herva, M., Álvarez, A., Roca, E., 2011. Sustainable and safe design of footwear integrating ecological footprint and risk criteria. Journal of Hazardous Materials, 192(3): 1876 ? 1881.

Houe, R., Grabot, B., 2007. Knowledge modeling for eco-design. Concurrent Engineering Research and Applications, 15(1): 7 ? 20.

Hur, T. et al., 2005. Simplified LCA and matrix methods in identifying the environmental aspects of a product system. Journal of Environmental Management, 75(3): 229 ? 237.

Jansen, A., Stevels, A., 2006. Combining eco-design and user benefits from human-powered energy systems, a win-win situation. Journal of Cleaner Production, 14(15-16): 1299 ? 1306.

Jeong, I.-T., Lee, K.-M., 2009. Assessment of the ecodesign improvement options using the global warming and economic performance indicators. Journal of Cleaner Production, 17(13): 1206 ? 1213.

Jeswiet, J., Hauschild, M., 2005. EcoDesign and future environmental impacts. Materials & Design, 26(7): 629 ? 634.

Jincheng, X., 2003. Ecodesign for wear resistant ductile cast iron with medium manganese content. Materials & Design, 24(1): 63 ? 68.

Johansson, G., 2006. Incorporating environmental concern in product development: a study of project characteristics. Management of Environmental Quality: An International Journal, 17(4), 421 ? 436.

_______., 2002. Success factors for integration of ecodesign in product development: a review of state of the art. Environmental Management and Health, 13(1): 98 ? 107.

Karlsson, R., Luttropp, C., 2006. EcoDesign: what’s happening? an overview of the subject area of ecodesign and of the papers in this special issue. Journal of Cleaner Production, 14(14 ? 15): 1291-1298, 2006.

Kengpol, A., Boonkanit, P., 2011. The decision support framework for developing Ecodesign at conceptual phase based upon ISO/TR 14062. International Journal of Production Economics, 131(1): 4 ? 14.

Knight, P., Jenkins, J.O., 2009. Adopting and applying eco-design techniques: a practitioners perspective. Journal of Cleaner Production, 17(5): 549 ? 558.

Kobayashi, H., 2006. A systematic approach to eco-innovative product design based on life cycle planning. Advanced Engineering Informatics, 20(2): 113 ? 125.

Kobayashi, H., 2005. Strategic evolution of eco-products: a product life cycle planning methodology. Research in Engineering Design, 16(1 ? 2): 1 ? 16.

Kuo, T.C., 2006. Enhancing disassembly and recycling planning using life-cycle analysis. Robotics and Computer-Integrated Manufacturing, 22(5 ? 6): 420 ? 428.

Kurczewski, P., Lewandowska, A., 2010. ISO 14062 in theory and practice-ecodesign procedure. Part 2: practical application. International Journal of Life Cycle Assessment, 15(8): 777 ? 784.

Le Pochat, S., Bertoluci, G., Froelich, D., 2007. Integrating ecodesign by conducting changes in SMEs. Journal of Cleaner Production, 15(7): 671 ? 680.

Lelah, A., Mathieux, F., Brissaud, D., 2011. Contributions to eco-design of machine-to-machine product service systems: the example of waste glass collection. Journal of Cleaner Production, v. 19(9 ? 10): 1033 ? 1044.

Lewandowska, A., Kurczewski, P., 2010. ISO 14062 in theory and practice-ecodesign procedure. Part 1: structure and theory. The International Journal of Life Cycle Assessment, 15(8): 769 ? 776.

Lim, S.-R. et al., 2013. System optimization for eco-design by using monetization of environmental impacts: a strategy to convert bi-objective to single-objective problems. Journal of Cleaner Production, 39, 303 ? 311.

Lofthouse, V., 2006. Ecodesign tools for designers: defining the requirements. Journal of Cleaner Production, 14(15-16): 1386 ? 1395.

_______., 2004. Investigation into the role of core industrial designers in ecodesign projects. Design Studies, 25(2): 215 ? 227.

Luttropp, C., Lagerstedt, J., 2006. EcoDesign and The Ten Golden Rules: generic advice for merging environmental aspects into product development. Journal of Cleaner Production, 14(15–16): 1396 ? 1408.

Luz, S.M., Caldeira-Pires, A., Ferrão, P.M.C., 2010. Environmental benefits of substituting talc by sugarcane bagasse fibers as reinforcement in polypropylene composites: ecodesign and LCA as strategy for automotive components. Resources, Conservation and Recycling, 54(12): 1135 ? 1144.

Malcolm, R., 2011. Ecodesign laws and the environmental impact of our consumption of products. Journal of Environmental Law, 23(3): 487 ? 503.

_______., 2011. Integrated product policy: products and their impact on energy. International Journal of Law in the Built Environment, 3(1): 48-64.

Maxwell, D., Sheate, W., Van der Vorst, R., 2006. Functional and systems aspects of the sustainable product and service development approach for industry. Journal of Cleaner Production, 14(17): 1466 ? 1479.

Maxwell, D., Van Der Vorst, R., 2003. Developing sustainable products and services. Journal of Cleaner Production, 11(8): 883 ? 895.

Mayyas, A.T. et al., 2012. Life cycle assessment-based selection for a sustainable lightweight body-in-white design. Energy, 39(1): 412 ? 425.

Michaud, F. et al., 2009. Meta-heuristic methods applied to the design of wood-plastic composites, with some attention to environmental aspects. Journal of Composite Materials, 43(5): 533 ? 548.

Michelini, R.C., Razzoli, R.P., 2004. Product-service eco-design: knowledge-based infrastructures. Journal of Cleaner Production, 12(4): 415 ? 428.

Morales, G. et al., 2010. EI scale - an environmental impact assessment scale related to the construction materials used in the reinforced concrete. Brazilian Archives of Biology and Technology, 53(6): 1511 ? 1518.

Muñoz, I. et al., 2009. LCA and ecodesign in the toy industry: case study of a teddy bear incorporating electric and electronic components. International Journal of Life Cycle Assessment, 14(1): 64 ? 72.

Muñoz, I. et al., 2006. Using LCA to assess eco-design in the automotive sector: case study of a polyolefinic door panel. International Journal of Life Cycle Assessment, 11(5): 323 ? 334.

Negny, S. et al., 2012. Toward an eco-innovative method based on a better use of resources: application to chemical process preliminary design. Journal of Cleaner Production, 32, 101 ? 113.

Nielsen, P.H, Wenzel, H., 2002. Integration of environmental aspects in product development: a stepwise procedure based on quantitative life cycle assessment. Journal of Cleaner Production, 10(3): 247 ? 257.

Pamfilie, R., Procopie, R., Bobe, M., 2010. Managing eco-design of industrial goods and consumers' protection nexus. Amfiteatru Economic, 12(28): 454 ? 465.

Park, P.-J., Tahara, K., 2008. Quantifying producer and consumer-based eco-efficiencies for the identification of key ecodesign issues. Journal of Cleaner Production, 16(1): 95 ? 104.

Passarini, F. et al., 2012. Auto shredder residue LCA: implications of ASR composition evolution. Journal of Cleaner Production, 23(1): 28 ? 36.

Pigosso, D.C.A. et al., 2010. Ecodesign methods focused on remanufacturing. Journal of Cleaner Production, 18(1): 21 ? 31.

Platcheck, E.R. et al., 2008. EcoDesign: case of a mini compressor re-design. Journal of Cleaner Production, 16(14): 1526 ? 1535.

_______., 2008. Methodology of ecodesign for the development of more sustainable electro-electronic equipments. Journal of Cleaner Production, 16(1): 75 ? 86.

Plouffe, S. et al., 2011. Economic benefits tied to ecodesign. Journal of Cleaner Production, 19(6-7): 573 ? 579.

Poudelet, V. et al., 2012. A process-based approach to operationalize life cycle assessment through the development of an eco-design decision-support system. Journal of Cleaner Production, 33, 192 ? 201.

Ramani, K. et al., 2010. Integrated sustainable life cycle design: a review. Journal of Mechanical Design, Transactions of the ASME, 132(9): 0910041 ? 0910041.

Ramirez, M., 2006. Sustainability in the education of industrial designers: the case for Australia. International Journal of Sustainability in Higher Education, 7(2): 189-202.

Rio, M., Reyes, T., Roucoules, L., 2013 Toward proactive (eco)design process: modeling information transformations among designers activities. Journal of Cleaner Production, 39, 105 ? 116.

Roy, R., 2000. Sustainable product-service systems. Futures, 32(3 ? 4): 289 ? 299.

Russo, D. et al., 2011. European testing of the efficiency of TRIZ in eco-innovation projects for manufacturing SMEs. Procedia Engineering, 9, 157 ? 171.

Russo, D., Regazzoni, D.; Montecchi, T., 2011. Eco-design with TRIZ laws of evolution. Procedia Engineering, 9, 311 ? 322.

Sakao, T., 2009. Quality engineering for early stage of environmentally conscious design. The TQM Journal, 21(2): 182 ? 193.

Sandström, G.Ö., Tingström, J., 2008. Management of radical innovation and environmental challenges: development of the DryQ capacitor at ABB. European Journal of Innovation Management, 11(2): 182 ? 198.

Santini, A. et al., 2010. Assessment of Ecodesign potential in reaching new recycling targets. Resources, Conservation and Recycling, 54(12): 1128 ? 1134.

Santolaria, M. et al., 2011. Eco-design in innovation driven companies: perception, predictions and the main drivers of integration: the Spanish example. Journal of Cleaner Production, 19(12): 1315 ? 1323.

Serres, N. et al., 2009. Dry coatings and ecodesign Part. 1: environmental performances and chemical properties. Surface and Coatings Technology, 204(1-2): 187 ? 196.

_______., 2009. Dry coatings and ecodesign Part. 2: tribological performances. Surface and Coatings Technology, 204(1-2): 197 ? 204.

Short, T. et al., 2012. Manufacturing, sustainability, ecodesign and risk: lessons learned from a study of Swedish and English companies. Journal of Cleaner Production, 37, 342 ? 352.

Shu-Yang, F., Freedman, B., Cote, R., 2004. Principles and practice of ecological design. Environmental Reviews, 12(2): 97 ? 112.

Spangenberg, J. H., Fuad-Luke, A., Blincoe, K., 2010. Design for Sustainability (DfS): the interface of sustainable production and consumption. Journal of Cleaner Production, 8(15): 1485 ? 1493.

Suárez-PEÑA, B., Asensio-Lozano, J., 2009. Una estrategia de ecodiseño de piezas obtenidas mediante moldeo a presión: análisis micro estructural aplicado a la desmaterialización. Revista de Metalurgia, 45(3): 181 ? 190.

Taieb, A.H. et al., 2010. Sensitising children to ecological issues through Textile Eco-Design. International Journal of Art and Design Education, 29(3): 313-3 ? 20.

Takáts, A., Takáts, P., 2011. Utilisation of coloured paper refuse in eco-products. Acta Silvaticaet Lignaria Hungarica, 7, 133 ? 146.

Tingström, J., Karlsson, R., 2006. The relationship between environmental analyses and the dialogue process in product development. Journal of Cleaner Production, 14(15–16): 1409 ? 1419.

Tingström, J., Swanström, L., Karlsson, R., 2006. Sustainability management in product development projects: the ABB experience. Journal of Cleaner Production, 14(15-16): 1377 ? 1385.

Trappey, A.J.C. et al., 2011. An eco- and inno-product design system applying integrated and intelligent QFDE and TRIZ methodology. Journal of Systems Science and Systems Engineering, 20(4): 443 ? 459.

Vakili-Ardebili, A., Boussabaine, A.H., 2007. Application of fuzzy techniques to develop an assessment framework for building design eco-drivers. Building and Environment, 42(11): 3785 ? 3800.

_______., 2010. Ecological building design determinants. Architectural Engineering and Design Management, 6(2): 111 ? 131.

Van Der Zwan, F., Bhamra, T., 2003. Alternative function fulfilment: incorporating environmental considerations into increased design space. Journal of Cleaner Production, 11(8): 897 ? 903.

Van Hemel, C., Cramer, J., 2002. Barriers and stimuli for ecodesign in SMEs. Journal of Cleaner Production, 10(5): 439 ? 453.

Vercalsteren, A., 2001. Integrating the ecodesign concept in small and medium-sized enterprises: experiences in the Flemish region of Belgium. Environmental Management and Health, 12(4): 347 ? 355.

Yang, C.J., Chen, J.L., 2011. Accelerating preliminary eco-innovation design for products that integrates case-based reasoning and TRIZ method. Journal of Cleaner Production, 19(9-10): 998 ? 1006.

_______., 2012. Forecasting the design of eco-products by integrating TRIZ evolution patterns with CBR and Simple LCA methods. Expert Systems with Applications, 39(3): 2884 ? 2892.

Yang, Q., Yu, S., Sekhari, A., 2011. A modular eco-design method for life cycle engineering based on redesign risk control. International Journal of Advanced Manufacturing Technology, 56(9-12): 1215 ? 1233.

Yu, J., Hills, P., Welford, R., 2008. Extended producer responsibility and eco-design changes: perspectives from China. Corporate Social Responsibility and Environmental Management, 15(2): 111 ? 124.

Yung, W. et al., 2011. A life-cycle assessment for eco-redesign of a consumer electronic product. Journal of Engineering Design, 22(2): 69 ? 85.

Yung, W.K.C. et al., 2009. Life cycle assessment of two personal electronic products-a note with respect to the energy-using product directive. International Journal of Advanced Manufacturing Technology, 42(3-4): 415 ? 419.

Zailani, S.H.M. et al., 2012. The impact of external institutional drivers and internal strategy on environmental performance. International Journal of Operations and Production Management, 32(6): 721 ? 745.

Zarandi, M.H.F. et al., 2011. A material selection methodology and expert system for sustainable product design. International Journal of Advanced Manufacturing Technology, 57(9-12): 885 ? 903.

Zhu, Q., Liu, Q., 2010. Eco-design planning in a Chinese telecommunication network company: benchmarking its parent company. Benchmarking, 17(3): 363 ? 377.

Zufia, J., Arana, L., 2008. Life cycle assessment to eco-design food products: industrial cooked dish case study. Journal of Cleaner Production, 16(17): 1915 ? 1921.

Zuidwijk, R., Krikke, H., 2008. Strategic response to EEE returns: Product eco-design or new recovery processes? European Journal of Operational Research, 191(3): 1206 ? 1222.

Zwolinski, P., Lopez-Ontiveros, M.A., Brissaud, D., 2006. Integrated design of remanufacturable products based on product profiles. Journal of Cleaner Production, 14(15-16): 1333 ? 1345.