HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN

HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN Espacios. Vol. 36 (Nº 07) Año 2015. Pág. 8

Elisandra Montes PIZYBLSKI a *; Antonio Augusto de Paula XAVIER a; Flávia TORRES a; Etianne Alves Souza de OLIVEIRA b

Recibido: 24/11/14 • Aprobado: 16/01/2015

ABSTRACT: |

RESUMO: |

The apparel industry is constituted mainly of micro, small and medium enterprises with diverse large-scale production and heterogeneity of products. Usually located in structured sheds or installed in commercial or residential buildings (SESI, 2003).

The goal of the textile industry is to transform the fibers into yarn, yarn into fabrics, and in a last moment turn fabrics in a wide variety of parts, such as: clothing (fashion and professional), parts of bedding, bath, table and technical applications (IEMI, 2010).

According to the Brazilian Association of Textile and Clothing Industry, the textile sector in Brazil presents very expressive values, since there are over 30.000 companies of all sizes, installed throughout the country, generating over 1.7 million jobs and 75% are female workforce. Brazil is the fourth largest textile producer in the world and has the fifth-largest industrial park of textile manufacturing the world (ABIT, 2012).

The industry of textile manufacturing comprises segments of clothing and accessories and is intensive in labor, whose main stage of the production cycle, sewing, absorbs 80% of the work (Nunes et. al. 2012).

"The main workforce of the textile manufacturing industry is comprised of females, due to the need for accuracy and delicacy in activities" (SESI, 2003, p. 19). The main equipment used in sewing is the sewing machine, which emerged in the mid-nineteenth century and has the same basic features until today (Scherer; Campos, 1995).

As regards the activity in discussion, it can be said that the seamstresses performing a cyclic activity, because when a sequence of tasks is completed, the same actions are repeated in another way. It is also observed that carriers of sewing machines do repetitive movements of the shoulders, arms, wrists, hands and fingers. Therefore, their activities have high repeatability of the movements of the upper limbs, which can result in musculoskeletal disorders (Sena et. al. 2008).

During the activity to sew many movements are executed, which require a visual tracking, meaning that the trunk and the head are inclined forward. Furthermore, neck and column are subjected to stresses maintained for long periods, causing pain. The back part can also be subjected to stresses when necessary to rotate the body, when the employee are on a fixed seat (Dul; Weerdmeester, 1995).

Therefore, the office of operator of sewing machines requires repetitive and coordinated use of the trunk, upper and lower extremities demonstrating a highly repetitive and monotonous activity that requires a high degree of concentration (Garcia, 2006; Paula et.al., 2009).

The manipulation combined with the realization of rapid, repetitive and continuous movements, with a work journey around 8 hours a day in a seated position can cause damage to the health of the seamstresses (Prado, 2006).

This work is justified by the importance of identify and characterize the profiles of occurrence of musculoskeletal symptoms in this population, with the aim of identifying actions aimed at improving the working conditions and health of these workers.

This research is characterized as quantitative, because according to Silva and Menezes (2005), the information can be translated into numbers to classify them; thus, we sought to identify the symptoms musculoskeletal seamstresses and quantify them.

As for goals (Gil, 1991) research can be descriptive as it aims to describe the discomfort or pain that the seamstresses are presenting during the workday.

With regard to the technical procedures, one can say that it is a survey research, with application of questionnaires and interviews with operators of sewing machines (Gil, 1991).

The present study was conducted in three industries of textile manufacturing industry, in the city of Ponta Grossa, Paraná. The companies were chosen by accessibility and interest in the research.

The first manufacturing textile industry entitled Enterprise A, have specialized in producing uniforms. Is consists of 23 employees, 17 of which are segment of the seam.

The second research industry, titled B, is responsible for producing shirts and has 16 employees. Of the total employees, nine are part of the sewing industry.

The third industry in study was the confection C that produces shirts and polo shirts, with 37 employees, 13 of these are seamstresses.

In the firms described above, the total number of employees includes all sectors of the enterprise: the administrative part, creation, production, purchasing, screen printing, embroidery, trimmings, shipping and sales. Adding to the total of employees of the three companies, have the total of 76 employees. For this research, we used only the operators of sewing machines, which totaled 39 seamstresses.

The function of the seamstresses was chosen for this research because the professionals spend approximately 8 hours of the workday sitting at their jobs (Picture 1), which can cause pain in the neck, shoulders, arms, hands, columns, legs and feet.

Picture 1- Workstation seamstresses

Source: SESI (2003, page.51)

The sample consisted of 39 female professionals, who play the role of seamstresses, operating many different sewing machines, like straight machine, serger and galoneira. Considering the age of the machine operators, the average age is 38 years, with a standard deviation of 8.63 years. The sample size was composed for all the workers, because it is statistically a small number of workers and voluntarily all of them agreed to participate.

To obtain the data, scheduled visits were made, and, for better accuracy of the data recorded in the questionnaires, we opted for the method of structured interviews, interviewing each worker individually, through the application of three questionnaires. The first refers to the identification data of workers to obtain demographic variable, occupational and lifestyle. The second was the diagram Corlett and Manenica (DCM) to identify the occurrence of musculoskeletal symptoms (Iida, 1990).

The third refers to the Oswestry index 2.0 of incapacity for work (Fairbank; Pynsent, 2000).

The DCM allowed calculation of the extent of musculoskeletal morbidity, enabling the association between this measure and the demographic and occupational variables. The instrument consists of choices as to the occurrence and intensity of symptoms of pain and discomfort in 22 body segments. The answers are presented in the diagram in the form of a Likert scale, showing the interviewee five alternative answers: no pain / discomfort; some pain / discomfort; enough pain / discomfort; intolerable pain / discomfort. The minimal possible response is equal to 22 questions with a minimum value of 1, representing no pain. The maximum possible response is equal to 110 questions with a maximum value of 5, which is intolerable pain in all body segments.

The Oswestry Scale consists of a recommended instrument for the evaluation of disorders of the spine which have 10 criteria with six alternatives for response. Each contains six affirmations, which progressively depict a higher degree of difficulty in activity than the previous statement (Fairbank; Pynsent, 2000). The total score ranges from 0 to 100, where each item is zero is normal and five is the largest functional alteration. The sum of 10 questions divided by five multiplied by the number of questions answered, and all multiplied by 100, became an index that is interpreted as follows: any dysfunction (0%), minimum dysfunction (1 to 20%), moderate dysfunction (21 to 40%), severe dysfunction (41 to 60%) and incapability (over 60%) (Santavirta et. al.1996).

Prevalence data are presented descriptively in the form of tables, graphs and percentages after processing in a spreadsheet.

With the implementation of tools for data collection there was obtained the following individual results: about sex, 100% of the sample consists of women (n = 39). The average age is 38.7 years (± 8.6 years). The average time of work at the company, is 107.3 months (± 91.6 months), or slightly more than 8 years.

On being asked about the realization of another parallel activity to the current job, 84.6% (n = 33) said they did not perform other activity, and only 15.4% (n = 6) said they have another job besides the work at the company.

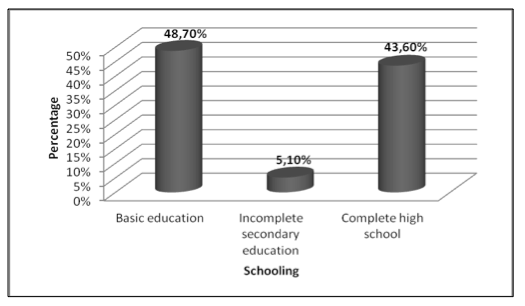

Picture 2 shows the prevalence of education level of the sample, the most part of the them have only primary education, with 48.7%.

Picture 2 – Educational level of the surveyed seamstresses

Source: Own Authorship

The data in the application diagram of Corlett and Manenica (DCM), showed that only 17.95% of seamstresses did not feel any pain and / or discomfort in the musculoskeletal system, most, 82.05% has pain reports.

These reports are shown in most cases with multifocal aspect, and coincidentally 17.95% indicated the presence of pain in different body segments while only 82.05% in one physical segment.

The data obtained with the application of the diagram Corlett and Manenica (DCM), showed that only 17.95% of the seamstresses did not felt any pain or discomfort in the musculoskeletal system, most, 82.05% presents reports of pain . In the majority of cases the seamstresses presented multifocal aspect, 17.95% indicate the presence of pain at the same time in different body segments and only 82.05% in a single body segment.

Table 1 - Occurrence of pain according to body region.

|

Left side |

Right side |

||

Body region |

n |

% |

n |

% |

Shoulder |

8 |

20,5 |

4 |

10,25 |

Arm |

2 |

5,12 |

1 |

2,56 |

Elbow |

1 |

2,56 |

4 |

10,25 |

Forearm |

0 |

- |

2 |

5,12 |

Wrist |

3 |

7,69 |

4 |

10,25 |

Hand |

2 |

5,12 |

3 |

7,69 |

Thigh |

1 |

2,56 |

3 |

7,69 |

Legs |

16 |

41,0 |

15 |

38,46 |

Souce: Own Authorship

With respect to anatomical regions, Table 2 shows the location of musculoskeletal symptoms in other body regions, also related to the period of the last twelve months.

Table 2 - Body Regions affected by pain.

Body regions |

n |

% |

Cervical Region |

11 |

28,20% |

Upper Back |

8 |

20,51% |

Middle of Coasts |

9 |

23,07% |

Lower Shore |

20 |

51,28% |

Basin |

5 |

12,82% |

Neck |

6 |

15,38% |

Source: Own Authorship

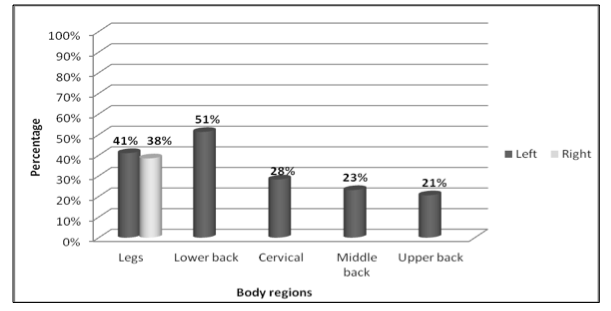

According to DCM (Diagram Corlett and Manenica), Picture 3 shows the regions most affected by musculoskeletal symptoms, such as pain, discomfort or tingling in anybody region in the past 12 months. It is observed that the regions with the highest incidence of musculoskeletal symptoms were the lumbar spine, with 51%, the middle of coasts with 23% and the upper coast region with 21%; followed by the region of the legs with 41% in the left hemisphere and 38% in the right.

Picture 3 – Body regions with higher prevalence of pain in workers surveyed

Souce: Own Authorship

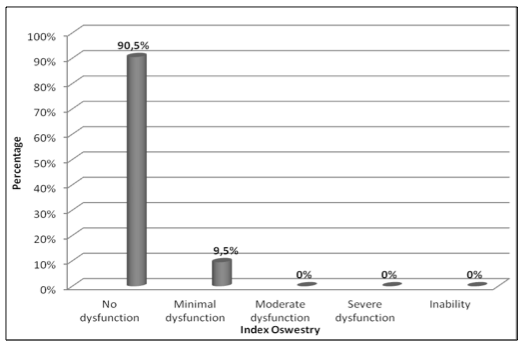

For the workers that showed lumbar pain at the DCM, was applied to Oswestry scale, according to which there wasn't a high incidence of low back pain caused by low back pain, because it was found that the dysfunctions was minimal (1 20%), as can be seen in Picture 4.

Picture 4 – Classification according to the Oswestry Scale for assessment of low back pain

Souce: Own Authorship

With the results, we can say that the seamstresses work presents several risks for developing diseases musculoskeletal, being a cyclical and monotonous activity being performed in a seated position for most of the workday. According to the results, most part of seamstresses, 51.28% have lower back pain. The second area of greatest discomfort is the cervical region with 28.20%, followed by middle of coasts, with 23.07% and upper coast with 20.51%. Regions with lower incidence of pain were the neck and pelvis with 15.38 and 12.82%, respectively.

Operators of sewing machines with low back pain totaled 51.28% and by analyzing the age group of employees with low back symptoms, it was noticed that the average age was 38.63 years (± 8.22 years), predominantly in their 30 and 40 years, which corresponds to 73.68% of the interviewees. The service time of seamstresses who had low back pain ranged from 2 months to 24 years, predominantly within the range of 10 to 19 years of service, which corresponds to 42.10% of the interviewees. Comparing survey results with those found by Oliveira et. al. (2004), there was a prevalence of low back pain in 26 seamstresses at a frequency of 73.07% in seamstresses with an average age of 25.21 years; compared to the average of this study that was 38.63 years. According to Jesus and Marino (2006), the average age of onset of back pain is around 35 years old, is uncommon below 20 years and above 60 years.

According to Ambrosi and Queiroz (2004), to activate the pedal and put the machine in motion, the seamstresses perform plantiflexon's and dorsiflexion's on the right foot, in addition to performing abduction of the right leg to raise the presser foot. Thus, the seamstresses use the right foot, the right leg and the right knee to operate the pedal of the sewing machines.

The seamstresses of this study showed greater discomfort in the right thigh, with 7.69% of that on the left, with only 2.56%. Regarding the legs, workers exhibited increased discomfort in the left leg 41.02% than the right leg, with 38.46%. It is evident that despite the operators of machines use more the right leg than the left, they feel pain on both sides, because they remain seated for most of the workday.

It is observed that the regions with the highest incidence of musculoskeletal symptoms were the region of the lower back, the middle of coasts, followed by the legs and shoulders, what is similar to the found in studies by Maciel et.al. (2006), where it was found that the sites with the highest prevalence of pain among professionals in the textile industry were the spine (cervical and thoracic), legs and shoulders.

Regarding complaints of pain, the lumbar region is the most cited (51.28%) between the symptomatic seamstresses. These data correspond to those research of Oliveira et. al. (2004), where there was a frequency of 73.07% of low back pain in seamstresses with age medium of 25.21 years.

It was observed that the dressmaking is predominantly made by, because 100% ofcthe sample was composed by women. According Guiraldelli (2012), the labor working in the garment industry is sharply feminine.

The daily workload of the seamstresses of this study is approximately eight hours and 45 minutes, five days a week, which is according to Freitas et. al. (2009), which found that the hourly load of operators of sewing machine era composed of 8.7 ± 0.9H, per day.

Throughout this research, it was realized that the seamstresses performed a cyclic activity. According to the studies of Sena et.al. (2008) after the execution of a sequence of tasks or termination of a work, the same sequence is repeated in the same way, or similarly.

The stitching is performed in the seated position, the sewing machine is situated on the top of the table with predetermined height by the manufacturer. The chair may or may not be adjustable. The fact of the chair and table weren't regulated can lead to postural discomfort. Some interventions can be made to promote comfort, like alternating positions and exercises, in addition to regular exercise, because according Kleinpaul (2008), the exercises can lead to the strengthening of the muscles of the pelvic girdle, helping to prevent backaches.

The sitting posture causes general discomfort, such as pain, heaviness and tingling in different parts of the body (Rodgher et. al. 1996). According to Mackenzie (1997) the main cause of low back pain and postural tension is bad posture, and staying in the same position for several hours can cause excessive stretching and prolonged of the ligaments and other soft tissues surrounding the joints.

The present study demonstrated a significant occurrence of pain in this population, and the region of highest occurrence of symptoms was the lumbar spine, followed by the region of the legs.

Therefore, we identified an ergonomic demand for this study population, which requires actions from the ergonomic point of view for the purpose of correcting postures that may overwhelm both the lumbar spine as the lower limbs, as well as physically modify the job aiming the improvement of working conditions for these seamstresses.

It is believed that this research serves as a basis for further studies in the textile industry companies, with the aim of identifying an ergonomic demand, and from there conduct further studies in order to propose actions aimed at decreasing the overload of the affected body parts, meaning the improvement of the conditions of these workers and consequently their overall health.

ABIT – Associação Brasileira da Indústria Têxtil e de Confecção. (2013); [Consultado: 14 junho 2014]. Disponível em: http://www.abit.org.br/site/navegacao.asp?id_menu=1&id_sub=4&idioma=PT

Ambrosi, D. ; Queiroz, M.F.F. (2004); Compreendendo o Trabalho da Costureira: um enfoque para a postura sentada. Revista Brasileira de saúde Ocupacional, v.29, n.109, p.11-19.

Corlett, E.N.; Manenica I. (1980); "The effects and measurement of working postures", Applied Ergonomics, 11: 7-16.

Dul, J.; Weerdmeester, B. (1995); Ergonomia prática. São Paulo, SP: Editora Edgard Blücher Ltda, 147p.

Fairbank, J.C. T.; Pynsent, P. B. (2000); "The Oswestry Disability Index", Spine; 25:2940-53.

Freitas, F.C.T., et al. (2009); Avaliação cinesiológica e sintomatológica de membros inferiores de costureiros industriais, Revista de Enfermagem. Rio de Janeiro: v.17, n.2, 170-175.

Garcia, J. A. C. (2006); Condições de trabalho e saúde dos trabalhadores da indústria do vestuário de Colatina, 2006, 123f, Dissertação (Mestrado em Saúde Coletiva) - Universidade Federal do Espírito Santo. Espírito Santo.

Gil, A.C. (1991); Como elaborar projetos de pesquisa; São Paulo, Atlas.

Guiraldelli, R. (2012); Adeus à divisão sexual do trabalho. Desigualdade de gênero na cadeia produtiva de confecção, Revista Sociedade e Estado, v.27, n.3, set./dez..

IEMI, Instituto de Estudos e Marketing Industrial. (2012); Relatório Setorial da Indústria Têxtil Brasileira 2010. Disponível em: <http://www.iemi.com.br/biblioteca/textil/brasil-textil-2010>. Acesso em: 20 nov..

Iida, I. (1990); Ergonomia - Projeto e Produção. São Paulo (SP): Edgard Blucher Ltda., 465 p.

Jesus, G.T.; Marinho, I.S.F. (2014); Causas de lombalgia em grupos de pessoas sedentárias e praticantes de atividades físicas. EFDeportes.com, Revista Digital. Buenos Aires, año 10, nº 92, enero de 2006. [Consultado: 15 abril 2014]. Disponível em: http: <//www.efdeportes.com/"www.efdeportes.com/efd92/lombal.htm

Kleinpaul, J. F., et al. (2014) Dor lombar e exercício físico. Uma revisão. EFDeportes.com, Revista Digital. Buenos Aires, año 13, n 127, diciembre de 2008. [Consultado: 19 abril 2014]. Disponível em: http://www.efdeportes.com/"www.efdeportes.com/efd127/dor-lombar-e-exercicio-fisico.htm

Maciel, A.C.C. et. al. (2006); Prevalência e fatores associados à sintomatologia dolorosa entre profissionais da indústria têxtil. Rev. Bras. Epidemiol. 9(1): 94-102.

Mackenzie, R. (1997); Trate você mesmo sua coluna. Nova Zelandia: Spinal Publications.

Nunes, J. H.; Campos A. F. (2006); O setor de confecção em Goiânia: análise da relação entre trabalho domestico e trabalho domiciliar. Sociedade e Cultura, v. 9, n. 2, p. 237-255.

Oliveira, M.C. et al. (2004); Prevalência de lombalgia em costureiras e correlação com a qualidade de vida e incapacidade. Arq. Ciênc. Saúde Unipar, Umuarama, 8(2), 111-119, maio/agosto.

Paula, A. J. F. et al.( 2009); Avaliação de Risco Ergonômico em Indústria de Confecção através do Método de Análise Postural Ovako Working Posture Analysing System - OWAS. In: CONGRESSO INTERNACIONAL DE PESQUISA DE DESIGN., 5.Anais. Bauru.

Prado, R. R. (2006); Avaliação da qualidade de vida na indústria do vestuário: o caso de costureiras portadoras de lombalgias. Dissertação (Mestrado). Universidade Estadual Paulista. Faculdade de Engenharia, Bauru.

Rodgher, S. et. al. (1996); Controle de desconfortos posturais em indivíduos que trabalham sentados: programa audio-visual. Revista Brasileira de Fisioterapia, v. 1, p. 21.

Santavirta, N.; et. al. (1996); "Sense of coherence and outcome of anterior low-back fusion: a 5- to 13- year follow-up of 85 patients", Arch. Orthop. Trauma. Surg.;115:280-285.

Scherer, A.; Campos, S. (1995); Projeto Competitividade e Inovação na Indústria Gaúcha: Cadeia Produtiva Têxtil–Vestuário. Porto Alegre FEE.

Sena, R. B. (2008); Análise dos riscos ergonômicos em costureiras utilizando o software Era (Ergonomic Risk Analysis) em uma empresa do polo de confecções do agreste de Pernambuco. In: XXVIII ENEGEP, Rio de Janeiro. Anais do XXVIII ENEGEP, p.1-7.

SESI. (2013); Manual de segurança e saúde no trabalho indústria do vestuário. São Paulo: SESI, 2003. [Consultado: 28 janeiro 2014]. Disponivel em: http://www.fiesp.com.br/indices-pesquisas-e-publicacoes/manual-de-seguranca-e-saude-no-trabalho-industria-do-vestuario/

Silva, E. L.; Menezes, E. M. (2014); Metodologia da pesquisa e elaboração de dissertação. 4. ed. Florianópolis: UFSC, 2005. [Consultado: 28 abril 2014]. Disponível em: https://projetos.inf.ufsc.br/arquivos/Metodologia_de_pesquisa_e_elaboracao_de_teses_e_dissertacoes_4ed.pdf

Souza, G. (2012); Materiais e Processo Têxtil. 2 ed. [Consultado: 20 abril 2014]. Disponível em: https://wiki.ifsc.edu.br/mediawiki/images/0/03/Apostila_de_MPTEX.pdf

a- Federal University of Technology, in Paraná, Post-graduation Program in Production Engineering, Campus Ponta Grossa PR, Brazil;

*Correspondingauthor. E-mail: lismopi@hotmail.com

b- Department of Higher Education, Federal Institute – Maranhão.