HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN

HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN Espacios. Vol. 37 (Nº 02) Año 2016. Pág. 22

Luiz Oliveira Veriano Dalla VALENTINA 1; Marilena Valadares FOLGUERA 2; Wanessa Rejane KNOP 3; Glaucia Aparecida PRATES 4

Recibido: 11/09/15 • Aprobado: 23/10/2015

ABSTRACT: This study aims to evaluate the potential use of exhauster powder generated in the foundry process as subproduct for a new product development. Formulations were prepared with different exhauster powder content. The sintered materials at 1000, 1100 and 1200°C were characterized according technological properties as water absorption, linear shrinkage and apparent density. Microstructural analysis was carried out by scanning electron microscopy. It was observed that the waste increase the density in sintering process and with high levels of waste occurs an increase of the porosity and intensification in the color of the new material. The formulations prepared with different exhauster powder content and this new material were characterization by thermal analysis (ATD, TG), and some technological properties such as water absorption, linear shrinkage, apparent density. Finally, were tested for resistance to bending, abrasion and the morphological analysis. The results showed the new material can be used as ceramic tiles, for, in general no significant changes it's physical and mechanical properties considering both ISO 10545-1:2014 and 13006:2012. |

RESUMO: Este estudo tem como objetivo avaliar o potencial de uso exhauster pó gerado no processo de fundição como subproduto para um novo desenvolvimento do produto. As formulações foram preparadas com diferentes conteúdos de exaustor de pó. Os materiais sinterizados a 1000, 1100 e 1200 ° C foram caracterizados de acordo com propriedades tecnológicas como a absorção de água, retração linear e densidade aparente. Análise microestrutural foi realizada por microscopia eletrônica de varredura. Observou-se que os resíduos de aumentar a densidade no processo de sinterização e com níveis elevados de resíduos ocorre um aumento da porosidade e intensificação da cor do material novo. As formulações preparadas com diferentes conteúdos de exaustor de pó e este novo material foram caracterização por análise térmica (ATD, TG), e algumas propriedades tecnológicas como a absorção de água, retração linear, densidade aparente. Finalmente, foram testadas quanto à resistência à flexão, abrasão e a análise morfológica. Os resultados mostraram que o novo material pode ser usado como telhas de cerâmica, para, em geral, não há mudanças significativas é propriedades físicas e mecânicas considerando tanto ISO 10545-1: 2014 e 13006: 2012. |

The byproducts are generated by casting from the molding process or any other, such as foundry slag, sand cores and molds, scrap iron, particulate matter, powders and exhaust of vapors and furnace waste liquids (SING, SIDDIQUE, 2012).

Many of these residues present in its composition elements present on ceramic raw materials, such as silicon and iron oxides, and carbonates (SIDDIQUE, SINGH , 2011). This fact motivates the ceramic industry as an alternative use of these products. As the raw materials used in the ceramic materials manufacture are natural, it is important to use alternative materials, thus decreasing the demand of elements taken from nature ( KNOP, 2009) .Therefore, this paper aims the physical and mechanical characterization of foundry solid powder exhaust as a new product, from a Brazilian company located in Joinville – SC, utilizing as methods an analysis of Scanning Electron Microscopy (SEM) for specimens with and without the incorporation of dust byproduct of exhaustion.

The dust depletion is caused in the manufacturing process of the mold sand, when the bentonita (clay), silica sand and coal during the metal parts production are mixed in the green sand production. One of the ceramic materials used to absorb more solid waste sectors is construction, specifically for manufacturing, bricks, cement and ceramic tiles. The byproducts are generated by casting from the molding process or any other, such as foundry slag, sand cores and molds, scrap iron, particulate matter, powders and exhaust of vapors and furnace waste liquids (SING, SIDDIQUE, 2012; KNOP , 2009).

In the green sand mold fabrication process for the production of metal parts, components are mixed in proportions set bentonite, coal dust and silica sand. These components pass through a vibrating conveyor where the thin this mixture which will not be part of the molds are removed. These fine removed in this process are called exhaust post, having reduced diameter and due to this prejudice the manufacture of metal parts, they restrict the exit of the gases contained in cast iron, bubbles occurring in parts (BITENCOURT , 2004).

And seeking alternatives to using foundry waste investigated the incorporation of the exhaust dust, slag and molten mass ceramic green sand, the results of the analysis of certain characteristics of the body-specimens were high strength mechanical and low values of water absorption, linear contraction, solubilization and leaching of heavy metals.

The applicability of foundry waste was studied by Chegatti (2004) (generated in the sand molding processes, breaks channels and exhaustion) in asphalt masses, red pottery and ceramic frits. Through the results it was possible to incorporate 10% by weight of waste both in asphalt mass as in red ceramic. For ceramic frits this concentration may reach 30 to 60% by weight, depending on the aesthetic requirements of the material being produced.

Thermal regeneration of sand dropped in the mold manufacturing process studied6 was concluded that the regenerated sands present particle size and chemical characteristics differentiated from each other and in relation to new sand, but do not affect the technological properties of tensile strength, but is reduced to life of the mixtures.

The study about incorporation into red ceramics resulted as low levels of leaching (Peixoto, 2003) and solubility coupled with adequate mechanical properties allow the use in red ceramic body in the formulation of 65% of foundry sand 20% glass micro spheres and 25% natural clay; Green Sand Casting incorporated in adhesive mortar for construction settlement searched that, as the amount of green sand residue embedded in the mortar increases, the resistance to both compression and significantly decreases the adherence and increases the uptake of the mortar and the empty index (MELLO, 2004).

As to the leaching results of the mortar, it was found that leaching values of the analyzed factors did not exceed specified limits; Hörlle ( 2003) analyzed the four types of viability waste incorporation: the first two from the sand molds used in casting iron, each with a type of phenolic resin, from the third spent sand used in the process (sand casting) and the fourth consisting of fine particles as filler in red clay ceramic materials, the best result was obtained containing 2% sand with phenolic resin was shown to have a strength 30% greater than that of pure clay; The use of casting sand used in roofing intermediate and final landfill as a result it was observed that the foundry sand residue showed higher potential for use as a final cover layer ( GOMES ; MORAES, 2007).

The embodiment is an alternative to use solid waste as a substitute for conventional raw materials, ie, an alternative raw material with lower value. The application of these new materials in partial or total replacement of the original raw material has become an appropriate application for industrial solid waste in forming new materials ( TEIXEIRA, 2006). Ceramic materials are commonly used for incorporation of by-products due to their characteristics and to have similarity with the original raw materials, the main effects are increased porosity and decreased shrinkage and mechanical strength of the finished material will depend on the amount of residue embedded. All industrial byproduct that has low particle size has a characteristic optimized for the ceramic industry, because it interferes in various properties such as plasticity of the mass, the sintering rate, the final porosity and density. In addition to raw materials with smaller particle sizes to minimize the cost of grinding. Other crystallographic chemical and physical characteristics similar to clays become necessary as a requirement for incorporation into ceramics (PUREZA et al, 2007).

A experiment used industrial casting products (casting slag, and exhaust green sand dust) and metalworking industries, such as waste glass to galvanic blasting and inert salts of the acid batteries for the preparation of ceramic composites and it showed that the use of these products as alternative raw material for red ceramic manufacturing is possible (bricks, tiles, floors, tiles, etc.) (BITENCOURT, 2004). They proved by tests performed on specimens obtained characteristics that consisted of high mechanical strength and low values of water absorption, linear contraction, solubilization and leaching of heavy metals. The results are due to the formation of vitreous structures and sintering of new crystalline structures. The properties obtained show that the new materials is conform to the Brazilian standards and reported further that through the results in leaching and solubilization materials developed have shown strong chemical bonding of heavy metals in relation to the materials.

A study the incorporation of three types of products, porcelain finish powder - PG byproduct of the atomizer - AT and flue dust - AC in two different clays (AA, AV) (PUREZA et al, 2007).

The incorporation of low granulometry of by-products promotes greater densification thereby reducing water absorption and increasing the linear shrinkage compared to ceramic bodies formulated with only clays firing temperatures from 850 ° C. The by-product powder atomizer presented in all firing temperatures, larger increments mechanical strength compared to other formulations investigated. All formulations at a temperature of 950 ° C showed a higher rate of densification of the clay formulations only.

Results showed of ornamental rock waste incorporation in bulk for vitrified ceramic tile floor (TEIXEIRA, 2006). The ceramic bodies with up to 47.5% of ornamental rock byproduct were sintered in 1190 will ° C using a rapid firing cycle. The results showed that the addition of ornamental rock modifies the by-product class to the type of glazed ceramic tile. The ceramic mass with 10% residue showed characteristics Bllb floors - Porous semi-(AA ≤ 6.0% ≤ 10.0%; σ ≥ 22 MPa). The mass of 20% by-product has characteristics of Biia floors - Semi stoneware (AA ≤ 3.0% ≤ 6.0%; σ ≥ 27 MPa). Since the masses 30%, 40% 47.5% byproduct and byproduct exhibited characteristics bib floors - stoneware (AA ≤ 0.5% ≤ 3.0%; σ ≥ 27 MPa).

The oil residue use viability as an alternative raw material in the manufacture of ceramic tiles with the following oil sludge percentage: 0; 1.25; 2.5 to 5% by residue weight (RIBEIRO, 2008). The results showed that the ceramic parts incorporated with the oil residue reached the appropriate characteristics for use as ceramic stoneware floor type according to the specifications of the ISO 13006 standard.

Both studies are presented as follow in order to show the characterization of foundry solid powder exhaust from a brazilian company located in Joinville - SC as an alternative raw material for ceramic coating by X-ray diffraction (XRD), thermal analysis (DSC) and thermogravimetric (TG). The dust depletion is caused in the manufacturing mold sand process, when the bentonita (clay), silica sand and coal during the metal parts production are mixed in green sand production. The raw materials were characterized through X-ray diffraction (XRD), thermal (DSC) and thermogravimetric analisys (TG). The atomized powder thermogravimetric analysis curve shows three intervals associated with the mass loss and it is typical of clay commercial application. The work evaluates the possibility of the use the exhauster powder generated in the foundry process in ceramic mass atomized semigre type. The raw materials used were semi-stoneware kind atomized powder used on the coating ceramic manufacturing and dust exhaust byproduct supplied by a foundry industry both from brazilian industries. Tests were conducted using a heating rate of 10 º.C / min and oxidant and / or inert atmosphere. Specimens contained different amounts of byproduct to the extent of 30% by mass, in order to verify the maximum addition of byproduct and were used in order to analyze the technological properties evaluation (water absorption linear shrinkage, bulk density). at the temperature of 1100° C showed higher difference between the results obtained and 1200º C this difference decreased (VALENTINA et al, 2015).

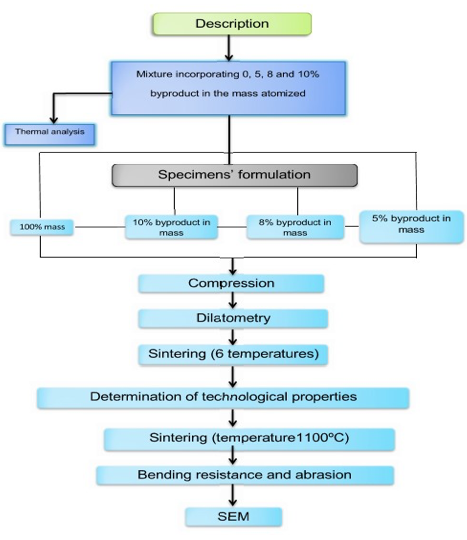

As showed in the figure 1, were made new specimens containing byproduct of proportions depending on the setting of this threshold in the previous step, with a maximum incorporation to 10% by mass and setting the sintering temperature through the data obtained experimentally and evaluation of the new materials properties.

The raw materials used were mass atomized semi-stoneware type used for manufacturing ceramic coating from a region of Tijucas industry – SC- Brazil, and powder byproduct of exhaust provided by a Joinville casting industry, in order to was assessing the feasibility of incorporating this material in ceramic body.

The atomized powder and the by-product were subjected to wet grinding in ball mill with four mixtures with different proportions: only atomized powder, and adding mass to 5%, 8% and 10% by-product powder exhaust. The grinding is effected, for a period of two hours, and then the slurries (suspension of the mass and more by-product water) were dried in an oven at 100 ° C ± 5 ° C.

After drying the material was passed in deagglomerated and 250 microns mesh sieve to acquire the proper material plasticity for pressing shaping was added 7% moisture by spraying and simultaneous manual homogenization. The compositions were determined proportions of 0, 5, 8, 10% by-product based on the initial stage and using as a criterion the behavior after sintering.

Figure 1. Experimental Details

The differential thermal analysis (DTA) and thermogravimetry (TG) for the four different formulations were performed on a Netzsch STA model 449C JUPTER machine using a heating rate of 5° C / min in an oxidizing atmosphere up to 1200° C temperature. Characterization mixture incorporating 0, 5, 8 and 10% byproduct in the sprayed mass bodies.

Development of the test piece thermal dilatometric analysis 100 t% by-product 5% by mass 10% by mass byproduct Sintering (temperatures 6). Determination of Properties Sintering Technology (temperatura 1100ºC) 8% byproduct mass bending resistance and abrasion Compression SEM.

A dilatometric analysis was performed using two specimens for each of the four compositions with dimensions 20mm x 5mm x 6mm and 1,60g each piece obtained by pressing (~ 40MPa). The dilatometric tests were performed on equipment model Netzsch Jupiter-Dil 402C at a heating rate of 5 ° C / min up to 1100 ° C temperature.

The vitrification curve is a graphical representation of the water absorption variations (AA) and specimens linear shrinkage (RL) with the sintering temperature. To build the vitrification curve, compressed up the specimens with dimensions of 31,5mm x12,5mm x6,5mm and 3,40g each and made up specimens measurements. Then the samples passed through the sintering in a muffle furnace at a heating rate of 15oC / min for 120 minutes at six different temperatures: 1000, 1050, 1100, 1125, 1150 and 1200 ° C. Subsequently measured the dimensions already at room temperature using a caliper with a resolution of 0.01 mm, thereby obtaining the linear shrinkage values.

The specimens were also weighed before and after sintering in a balance with a resolution of 0,001g to determine the technological properties: water absorption and apparent density.

For abrasion and flexural strength tests were shaped specimens 3 and 5 respectively for each composition with the following dimensions 70mm x30mm x12mm and 33,5g mass each, at approximately 40MPa compression pressure. They were then sintered at 1100 ° C temperature in a muffle furnace model Jung with a heating rate of 15oC / min for 120 minutes and subsequently to the mechanical strength and abrasion test that were conducted in the laboratories of Senai Criciuma / CTCmat through the method of the three-point bending / PR-CC-085 and abrasion resistance deep determination (unglazed samples) performed according to ISO 10545.

2.7. Scanning electron microscopy (SEM) was performed the morphological characterization of the specimens sintered will 1100 ° C with the addition of 5, 8 and 10% by product mass and mass only, using the technique of scanning electron microscopy.

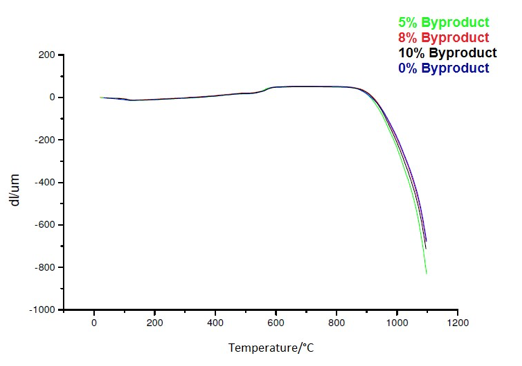

The raw materials passed through the wet milling and sieved to eliminate segregation and promote contact between these, and then were mixed at a ratio of 5, 8 and 10% by-product in the dough and evaluated by the their thermal behavior and the thermal dilatometric analysis. The dilatometric curve of the incorporation of 5, 8 and 10% by weight of by-product and without the incorporation of the byproduct to a temperature of 1100 ° C (Figure 2) shows that they have a similar behavior. Around 500 to 600 ° C there is a slight expansion which can be related to the transformation of alpha quartz to beta quartz. From 900oC occurs a sharp downturn resulting from the formation of liquid phase favoring sintering. Note that this is similar between the characteristic curves occur at the same temperature this is indicative that the byproduct has no action on the molten mass as it did not lower the specimens liquid-phase formation temperature with no byproduct embodiments.

Figure 2. Dilatometric analysis of specimens with incorporation of 5, 8 and 10% by weight byproduct

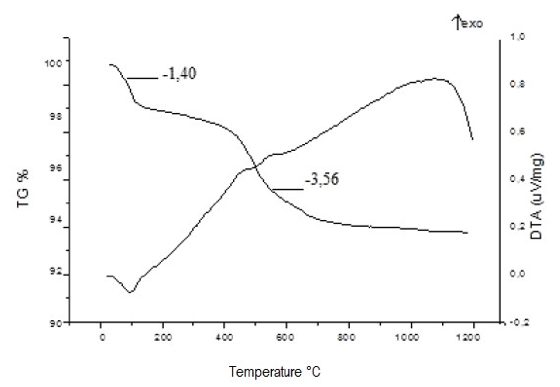

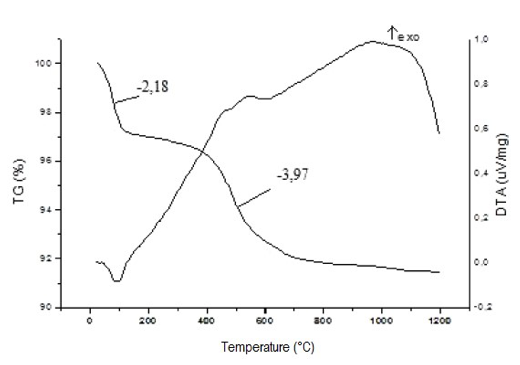

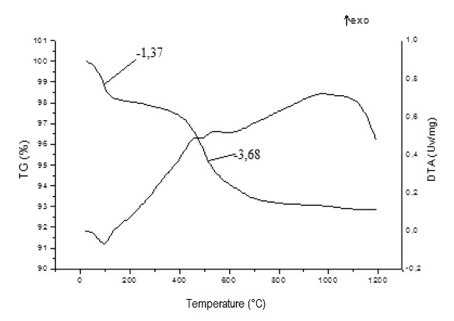

The thermal mass change resulting from incorporation of by-product containing 5, 8 and 10% are illustrated by Figures 3, 4 and 5 respectively. Observing the behavior of the curves it may be said to approximately 100 ° C there was a weight loss in all the three samples (5, 8 and 10%, respectively) of approximately 1.4%, 1.37% and 2.18% by loss the natural moisture of the clay. Between 100 and 400 ° C the weight loss is due to the oxidation of organic matter. There are two exothermic events between 400 and 800 ° C which may be associated with dehydroxylation and / or decomposition of clay minerals and will transform the alpha quartz to beta quartz that can be checked also by dilatometric analysis. Related to these events the

weight loss is of the order of 3.56, 3.68 and 3.97% respectively for samples 5, 8 and 10% by weight of by-product. For thermal analysis of samples incorporation of 5, 8 and 10% weight by-products shown there is no significant variation between the curves showing similar events in the three samples. Noting that as it increased the amount of by-product increased the total mass loss, probably due to the amount of clay minerals and organic matter present in byproduct.

Figure 3. Thermal analysis with 5% embedded byproduct in the sprayed mass.

-----

Figure 4. Thermal analysis with 8% incorporated by-product in the mass atomized

-----

Figure 5. Thermal Analysis incorporated with 10% by-product in atomized powder.

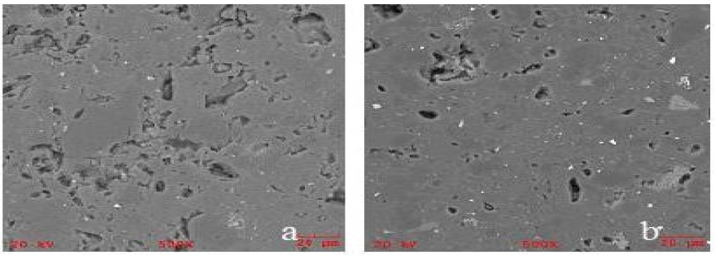

Based on the weight loss values obtained by thermal analysis only byproduct and mass were correlated with the weight loss obtained by thermal analysis values of the mixtures (5, 8, 10 and 30%) is observed that for the mixture there is the same ratio to the theoretical mass loss indicates that it did not form with heating new volatile compounds. In this second stage were changed processing conditions where it is expected with the best features and eliminating clusters of greater homogeneity as can be seen by Figures 6 and 7.

For the mass of the preliminary stage (Figure 6) showed the highest amount of agglomerates to the mass of the second step (Figure 6-b) with higher densification due to better processing.

Figure 6. SEM micrographs of the mass preliminary step (a) and

second portion (b) sintered at 1100 ° C with increased 500x.

By incorporating 15% by weight of by-product (Figure 7-a) displays a greater porosity and shape difference and the grain size and quantity of the same in relation to 10% by weight of by-product to presence of pores and less rounded, this is reflected in the mechanical properties being expected less by product content has greater mechanical strength.

Figure 7. SEM micrographs of the incorporation of 15% by weight byproduct preliminary step (a) and

10 mass% byproduct second part (b) sintered at 1100 ° C with increased 500x. 5

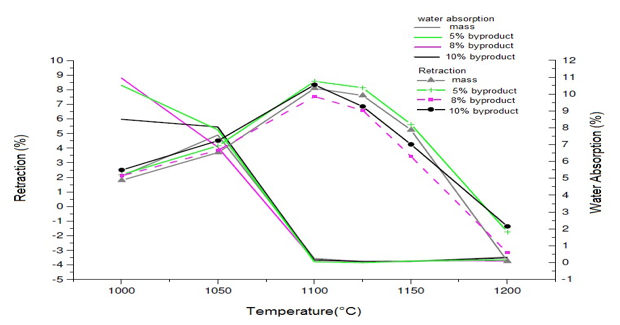

The behavior during sintering with respect to water absorption characteristics, linear shrinkage with byproduct of incorporation of 5, 8 and 10% and without the incorporation can be observed by vitrification curve, showed at Figure 8.

The vitrification diagram was constructed in order to assess the behavior of this mass with the incorporation by product and indicate the best sintering temperature for specimens used to carry out the bending and deep abrasion tests. In 1000 o C is linear shrinkage between 1.8 and 2.5% indicating that has happened the os sintering beginning as seen by dilatometry. It can be seen that the linear shrinkage increases to a certain temperature (1100 ° C) from which lowers the shrinkage and expansion occurs due to gases trapped in the pores leading to swelling of the ceramic body. The greatest expansion occurs in specimens only the mass temperature at 1200 ° C and the byproduct incorporation in all proportions expanded least verifying that the byproduct has no negative effect on the dough. This expansion of the gases leads to the presence of larger pores than at lower temperatures increase the closed porosity, open porosity but should decrease because the glass amount phase tends to increase explained by the lower final values of water absorption formed on heating the material. With increasing temperature above 1100 ° C has no significant effect on water absorption values. Note that the most suitable temperature for processing the specimens is 1100 ° C, in view of low water absorption values which occurs at this temperature until the retraction body-specimens and above this temperature starts expansion (Figure 8), which is not interesting in this case because the expansion causes cracks and warping with the dimensional instability of the ceramic piece. This temperature was probably defined by the mass as it is in predominant amount in the sample.

Figure 8. Vitrification and contraction curve values and water absorption in the specimens with the incorporation of

5, 8 and 10% by-product and the sintered mass atomized into six different temperatures.

-----

Table 1. Vitrification and contraction curve values and water absorption in the samples

with the incorporation 5, 8 and 10% by-product and the sintered mass atomized into six different temperatures.

Water Absorption |

1000°C |

1050°C |

1100°C |

1125°C |

1150°C |

1200°C |

0% byproduct |

(5,1±1,1) |

(7,57±0,38) |

(0,25±0,12) |

(0,066±0,066) |

(0,08±0,96) |

(0,33±0,20) |

5% byproduct |

(10,5±0,11) |

(7,88±0,93) |

(0,06±0,11) |

(0,00±0,067) |

(0,09±0,12) |

(0,17±0,16) |

8% byproduct |

(10,9±0,64) |

(6,85±0,54) |

(0,15±0,18) |

(0,068±0,068) |

0,10±0,17) |

(0,110±0,068) |

10% byproduct |

(8,5±1,9) |

8,05±0,78) |

0,16±0,21) |

0,069±0,069) |

0,07±0,16) |

(0,29±0,24) |

Retration |

1000°C |

1050°C |

1100°C |

1125°C |

1150°C |

1200°C |

0% byproduct |

(1,80±0,16) |

(3,697±0,018) |

(8,08±0,11) |

(7,598±0,065) |

(5,24±0,21) |

(3,75±0,57) |

5% byproduct |

(2,19±0,16) |

(4,16±0,10) |

(8,57±0,25) |

(8,129±0,065) |

5,63±0,22) |

(1,74±0,17) |

8% byproduct |

(2,11±0,22) |

(3,86±0,14) |

(7,53±0,16) |

(6,581±0,065) |

3,43±0,13) |

(3,16±0,13) |

10% byproduct |

(2,50±0,14) |

(4,51±0,23) |

(8,33±0,21) |

(6,851±0,065) |

(4,25±0,61) |

(1,36±0,17) |

Due these factors, it was decided to use this temperature for sintering to the sequence of tests.

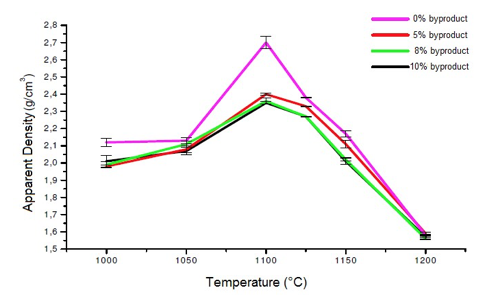

Figure 9 shows the density values for the four materials, observing similar behaviors values and trend as the sintering temperature increased to 1100 ° C temperature variation in mass in relation to the specimens with the byproduct that had the highest values for the apparent density in all sintering temperatures. The reduction in density values may be related to the apparent increase of closed porosity in the ceramic parts due to dust byproduct of exhaust added.

The behavior trend is similar in the two stages of the study, however in the second stage the obtained values are presented larger. In 1200 ° C the values of apparent density are similar indicating have no influence for this property at this temperature over dough.

Figure 9. Variation of the apparent density of the specimens at five different temperatures.

-----

Table 2. Variation of the specimens apparent density at five different temperatures.

Apparent Density |

1000°C |

1050°C |

1100°C |

1125°C |

1150°C |

1200°C |

0% byproduct |

(2,116±0,024) |

(2,131±0,017) |

(2,701±0,034) |

(2,383±0,002) |

(2,174±0,019) |

(1,588±0,007) |

5% byproduct |

(1,980±0,007) |

(2,081±0,020) |

(2,403±0,005) |

(2,330±0,002) |

(2,108±0,023) |

(1,591±0,007) |

8% byproduct |

(1,988±0,017) |

(2,108±0,018) |

(2,364±0,018) |

(2,269±0,002) |

(2,020±0,010) |

(1,559±0,006) |

10% byproduct |

(2,006±0,033) |

(2,065±0,021) |

(2,354±0,008) |

(2,266±0,002) |

(2,009±0,019) |

(1,570±0,010) |

For this experiment has been produced three sections of the test piece for each analyzed characteristic and also set the average value and measurement uncertainty. This uncertainty consists of the measurement system error and variation of the specimens as shown in Figures 8 and 9, and also the byproduct had no significant interference in the behavior mass related to water absorption values with the values coinciding in the same measuring range 1100 ° C in temperature. In the case of apparent density values only with the atomized powder were larger at all sintering temperatures.

The density values for the materials with the incorporation of minor by-product were due to the presence of organic matter how difficult the gases and porosity greater densification, this behavior is the same in both stages.

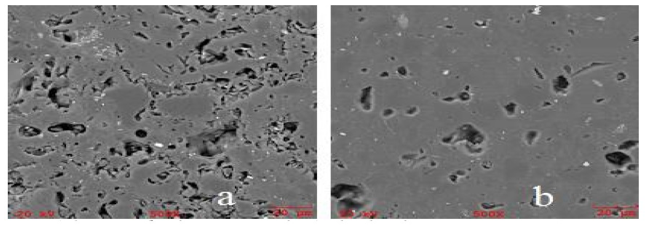

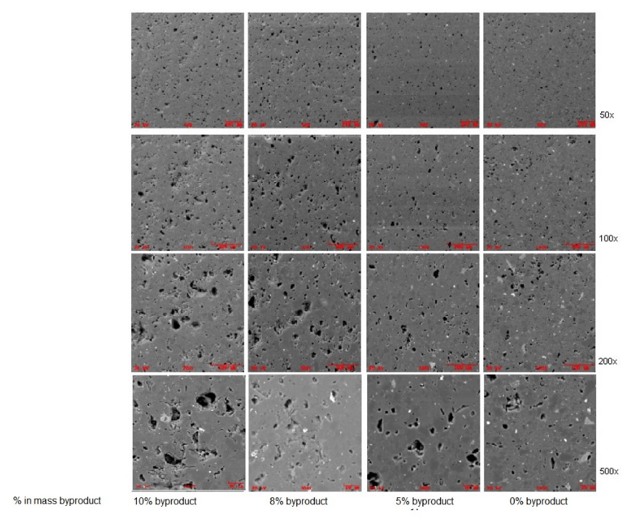

In Figure 10 are present the most representative micrographs of polished surfaces of the samples with incorporation of 5, 8 and 10% by weight of by-product after sintering at 1100 ° C. The microstructures obtained by Scanning Electron Microscopy (SEM) show the evolution of porosity with the incorporation of by-product, this porosity results from the removal of volatiles from the decomposition of by-product components, with magnification micrographs of the observed increased formation of rounded pores and isolated possibly constituting a closed porosity explaining low water absorption values, wherein the pore size increases with increasing byproduct content. It is due probably to incorporation of by-product and processing conditions.

Figure 10. Micrographs of specimens with incorporation of 5, 8 and 10% and only by-product

of the mass with a magnification of 50, 100, 200 and 500x, sintered at 1100 ° C.

It can be seen in figure 10 with 500x magnification micrograph that the mass presents less porosity and 8% by weight of by-product has smaller pores than the micrographs 5 and 10% by weight of by-product with higher porosity and that the presence of these pores flat is also higher, and it reflected in the mechanical properties. The degree of voltage amplification depends on the length of the crack and the radius of curvature of the crack tip being larger in the case of long pointed defects. If flattened pores that more concentrated stress at a point is easier to occur cracks to rounded pores and has the effect of concentration of specific softening point of crack propagation. Thus it is expected that for sample 5 and 10% mass by-product has low bending resistance.

This assay measures the physical-mechanical stress undergone by the specimens of an unglazed ceramic plate, which consists in measuring the volume of material removed from the workpiece surface, and the result is expressed in mm3. The deep abrasion indicates the tread wear resistance not from its surface, but the ceramic support (thickness reduction due to wear and tear), occurred during the years 17. The table 3 presents the deep abrasion of the sintered compositions to 1100 ºC.

Table 3. Resistance to abrasion compositions of sintered at 1100 ° C.

Formulations (% in mass) |

0% byproduct |

5% byproduct |

8% byproduct |

10% byproduct |

Deep abrasion (volume of the cavity) |

(133±12) |

(148±11) |

(146±13) |

(125±4) |

The tests showed a tendency to decrease the amount of abrasion for the specimens with the highest percentage of built-in mass by-product. It was found that this property is not influenced by the material porosity.

Even with this material porosity (by-product with incorporation) showed more abrasion resistant layers in relation to the material without the incorporation of the byproduct. Thus, with regard to abrasion resistance can be concluded that the incorporation of the byproduct not interfere with the behavior of the material.

Table 4 shows the values of technological properties found for sinter at 1100 ° C. In this context the properties generally used for rating of ceramic plates as water absorption, abrasion resistance and deep bending resistance that will specify the acceptable values to these characteristics ISO 13006 20 standard was followed. In addition, the values were analyzed the respective linear shrinkage after sintering, which although not specified in the technical standards is an important property of dimensional stability of the ceramic coatings should preferably be between 5-9% 18 to analyze the results obtained for the new materials.

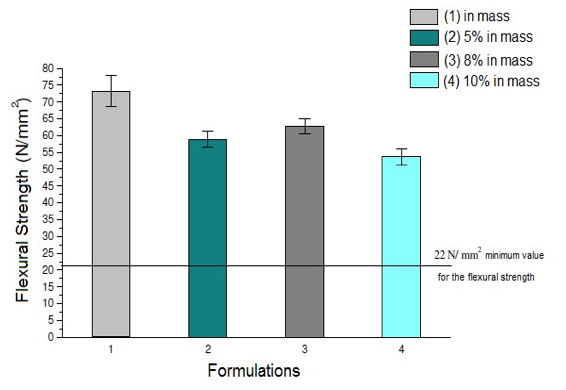

According to Table 4 the values for the water absorption (AA) in all compositions are within the amounts required for the semi-stoneware mass Biia group (AA 3 to 6%). Regarding the resistance to bending which should present the minimum value of 22N / mm2 in all experimental results presented in Figure 5.11.

Figure 11. Values of flexural strength for the sintered samples to 1100 ° C

Materials were also within the required parameters. Taking into account that value for the abrasion resistance must be ≤170mm3.

Therefore all materials were accepted. For the retraction values, this property should be about 5 to 9% which were achieved by the analyzed material ( DONDI et al, 2002).

In general, there were no significant changes in physical and mechanical properties studied the ceramic mass by incorporating the powder byproduct exhaust. It was concluded it is also not recommended for greater incorporation than 10% by-product due to increasing porosity of this material, as evidenced by the SEM micrographs.

Table 4: Values respective technological properties found for compositions

0, 5, 8 and 10% byproduct sintered at 1100 ° C.

Technological properties |

Byproduct of incorporation |

|||

|

0% |

5% |

8% |

10% |

Water absorption(%) |

(0,25±0,12) |

(0,06±0,11) |

(0,15±0,18) |

(0,16±0,21) |

Linear shrinkage(%) |

(8,08±0,11) |

(8,57±0,25) |

(7,53±0,16) |

(8,33±0,21) |

Density apparent (g/cm3) |

(2,701±0,034) |

(2,403±0,005) |

(2,364±0,018) |

(2,354±0,008) |

Deep abrasion (mm3) |

(133±12) |

(148±11) |

(146±14) |

(125±4) |

Flexural strength (N/mm2) |

(73±4) |

(59±2) |

(63±2) |

(58±2) |

Based on the investigations carried out in the present research, the following conclusions can be presented:

• The powder byproduct of exhaust presents an important characteristic for the industry ceramic therefore consists of particles with smaller particle size, which eliminates the grinding or milling byproduct prior to the formulation step, minimizing the costs. In this context, the by-product replacement with a low granulometry and characteristics similar chemical and physical mass were similar presenting be a viable alternative.

• The by-product in the mass does not behave as inert material, existing interaction in mass.

• Observed that the byproduct shows mass loss mass greater than the mass only, it interferes with the process requiring adjustment to its incorporation.

• For temperatures above 1100 ° C will there is a significant expansion of what effect shows the impracticability of these for ceramic floors, but only with this mass effect also occurred.

• The results for the compositions were different in value not in trend the difference in processing steps.

• The incorporation of the byproduct resulting in the apparent decrease in density resulting in lighter materials, which reflects the thermal comfort as an advantage.

Our special acknowledgments laboratories of Senai Criciuma / CTCmat, located in Santa Catarina- Brazil. For the company that supplied the powder industrial by-product of exhaustion for the study and the coatings company that gave the atomized ceramic. At PROMOP for the scholarship granted and especially to Prof. Dr. Masahiro Tomiyama.

1. SINGH G; SIDDIQUE R. (2012); "Effect of waste foundry sand (WFS) the partial re-placement of sand on the strength, ultrasonic pulse velocity and permeability of concrete", Construction and Building Materials, 26,(4) 416-422.

2. SIDDIQUE R; SINGH G. (2011); "Utilization of waste foundry sand (WFS) in concrete manufacturing", Resources, Conservation and Recycling, 55, 885-892.

3. KNOP, W.R. (2009); Feasibility study of the Merger Exhaust powder in Ceramics Mass. [Dissertation] Joinville: State University of Santa Catarina-UDESC.

4. BITENCOURT, ER. (2004); Use of Alternative Raw Materials in Red and White Clay Brick Manufacturing. [Dissertation] Joinville: University of the State of Santa Catarina, UDESC.

5. CHEGATTI, S. (2004); Foundry waste application on asphalt, ceramic ceramics and red chips. [Thesis] Florianopolis: Federal University of Santa Catarina, UFSC.

6. PEIXOTO F. (2203); Thermal regeneration of sand chemically bound. [Dissertation] Joinville: University of the State of Santa Catarina, UDESC.

7. TOLEDO, E B S. (2006); Foundry sand blasting and method of use of waste dust (glass microspheres) to produce red ceramics.[Dissertation] Curitiba; Federal University of Paraná.

8. MELLO, O J.(2004); Study the feasibility of reusing green sand casting residue on adhesive mortar. - Environmental focus. [Dissertation] Blumenau: University of Blumenau Regional Center of Technological Sciences.

9. HÖRLLE LF ; BASEGIO TM ; BERGMANN CP. (2003); Incorporation of foundry waste in ceramic red clay. In: Regional XVIII Congress of Scientific and Technological Initiation, Porto Alegre, Brazil.

10. GOMES LP ; MORAES C AM; BOFF RD.(2007); "Employment sand used in foundry covers intermediate and final sanitary landfills" .Technology in Metallurgy and Materials, 3(4), 71-76.

11. PINHEIRO, B C A ; HOLLAND JNF. (2009); Bodies of characterization Ceramic Vitrified Embedded with Oil residue. Brazilian Conference of Materials Engineering and Science; Joinville, Brazil.

12. PUREZA JC; VINCENZI CJ; BERGMANN CP. (2007); "Use Low Particle size waste as raw material in the production of Red Ceramics: Considerations about the sintering mechanisms". Industrial ceramics. 12 (3).

13. TEIXEIRA SS. (2006). Influence of oily residue incorporation of the oil sector in the microstructure of clay pottery. In: 17th Brazilian Congress of Engineering and Materials Science, Foz do Iguaçu, Brazil.

14. RIBEIRO, R A C. (2008); Development of new ceramic materials from industrial waste metal - mechanics. [Dissertation] Curitiba: Federal University of Parana technology sector.

15 VALENTINA LOVD,; FOLGUERA MV,; KNOP WR; NASCIMENTO MCP; PRATES GA. (2015); "Quality Technological Properties of Foundry Exhaust Dust as Alternative Ceramic Coating Raw Materials". Advanced Materials Research, 1088(20), 395-398.

16. VALENTINA LOVD,; FOLGUERA MV,; KNOP WR; NASCIMENTO MCP; PRATES GA. (2014); "Quality Characterization of Iron Dust Exhaust Thermal as Alternative Ceramic Coating Raw Materials in a Brazilian Company" , Advanced Materials Research, 1077(12), 135-138.

17. EFFTING, C. (2008); Development comfortable ceramic tile heat. [Thesis] Florianopolis: Federal University of Santa Catarina, UFSC.

18. DONDI M; GUARANI G; RAIMONDO M; RUFFINI I A. (2002); "Orimulsion fly ash in clay bricks-part 3: chemical stability of ash-bearing products", Journal of the European Ceramic Society, 22, 1749-1758.

19. INTERNATIONAL ORGANIZATION FOR STANDARDIZATION – (2014); ISO. ISO 10545-1:2014. test-part 1, Sampling and basis for acceptance. ISO.

20. INTERNATIONAL ORGANIZATION FOR STANDARDIZATION (2012) – ISO. ISO 13006:2012- Ceramic tiles -- Definitions, classification, characteristics and marking. ISO.1. Materials Science and Engineering Program UDESC , UNISOCIESC- Joinville- SC. Brazil Brazil . luiz.valentina@udesc.br

2. Materials Science and Engineering Program UDESC- Joinville- SC. Brazil marilena.folgueras@udesc.br

3. Materials Science and Engineering Program UDESC Joinville- SC. Brazil wrknop@yahoo.com.br

4. Faculty of Wood Industrial Engineering, State University of São Paulo, UNESP- "Júlio de Mesquita Filho", Itapeva, 18.409-010, Brazil. glaucia@itapeva.unesp.br