Vol. 38 (Nº 23) Año 2017. Pág. 22

Igor Leonidovich VOROTNIKOV 1; Magomet Shayhovich GUTUEV 2; Konstantin Aleksandrovich PETROV 3; Oleg Aleksandrovich ESIN 4

Recibido: 24/11/16 • Aprobado: 12/12/2016

ABSTRACT: The main constraint on the technical and technological modernization of Russian agriculture as a whole and individual regions, in particular, is the state of the machine and tractor fleet. Today, supply of agricultural enterprises with agricultural machinery is 40-50% of the regulatory requirements. Over the past 5 years there has been a significant reduction in the machine and tractor fleet that had led to reduction of specific energy supply per unit of cultivated area up to 1.2 hp / ha (at the rate of 3 hp/ha), and to increase in the existing equipment load as well as the number of failures. This reduction is also determined by a violation of the ratio between the number of incoming machinery and machinery outgoing because of its wear and tear. Thus, compliance with agronomical time limits of agricultural production in energy-intensive field work depends largely on the service enterprises that are to respond to the equipment failure as quickly as possible and to repair it in a quality manner. Maintenance service is carried out by mobile teams. Saratov region is characterized by large geographic extent, which is reflected in the increase in transport costs of service companies, outage of agricultural equipment and, consequently, in agro-industrial complex effectiveness reduction. Based on the above, the organization of regional technical service needs improvement and rationalization within the priority research area "Modernization of engineering support of agro-industrial complex" (registration number 01201151795). The necessity of improving technologies of repair and maintenance of agricultural machinery is grounded. It is developed a model to optimize service operations. Advantages of the proposed optimization for dealerships and agricultural producers are marked. |

RESUMEN: El principal obstáculo a la modernización técnica y tecnológica de la agricultura rusa en su conjunto y de sus regiones, es el estado de la flota de máquinas y tractores. Hoy en día, el suministro de las empresas agrícolas con maquinaria agrícola es de 40-50% de los requisitos necesarios. En los últimos 5 años se ha producido una reducción significativa de la flota de máquinas y tractores que ha llevado a la reducción del suministro específico de energía por unidad de superficie cultivada hasta 1,2 hp/ha (a razón de 3 CV / ha) debido al aumento de la carga de equipo existente, así como el número de fallos. Esta reducción también se determina por una errada relación entre el número de maquinaria entrantes y salientes debido a su desgaste. Por lo tanto, el cumplimiento de los plazos agronómicos de la producción agrícola en el trabajo de campo depende en gran medida de las empresas de servicios que deben responder al fallo de los equipos tan pronto como sea posible y repararlo con calidad. El servicio de mantenimiento es llevado a cabo por equipos móviles. La región de Saratov se caracteriza por una gran extensión geográfica, lo que se refleja en el aumento de los costos de transporte de las empresas de servicios, la interrupción de los equipos agrícolas y, en consecuencia, en la reducción de la eficacia agroindustrial. Sobre la base de lo anterior, la organización del servicio técnico regional necesita mejoras y racionalización dentro del área de investigación prioritaria "Modernización del soporte de ingeniería del complejo agroindustrial". Este estudio se basa en la necesidad de mejorar las tecnologías de reparación y mantenimiento de la maquinaria agrícola por lo que se desarrolla un modelo para optimizar las operaciones de servicio. Las ventajas de la optimización propuesta para concesionarios y productores agrícolas están evaluadas. |

Modern agricultural machinery is complex, high-tech equipment. It performs most operations during the sowing and harvesting work, as well as handling of plants. Over the past 5 years there has been a significant reduction in machine and tractor fleet, resulting in specific energy supply reduction per unit of cultivated area up to 1.2 hp/ha (at the rate of 3 hp/ha), in increase in the existing equipment load on and, as a consequence, increase in the number of impending damage. In the Saratov region, provision of agricultural enterprises with agricultural machinery is now 40-50% of the regulatory requirements. Reduced availability of agricultural businesses with essential equipment is also due to violation of the ratio between the number of new and old (because of wear and tear) machinery. It is the main limiting factor of technical and technological modernization of agriculture.

Thus, compliance with agronomical terms of agricultural production in energy-intensive field work depends largely on the service enterprises that are to respond to the equipment failure as quickly as possible and to repair it in a quality manner. Maintenance service is carried out by mobile teams. Saratov region is characterized by large geographic extent, which is reflected in the increase in transport costs of service companies, outage of agricultural equipment and, consequently, in agro-industrial complex effectiveness reduction. Based on the above, the organization of regional technical service needs improvement and rationalization within the priority research area "Modernization of engineering support of agro-industrial complex" (registration number 01201151795) [7-10].

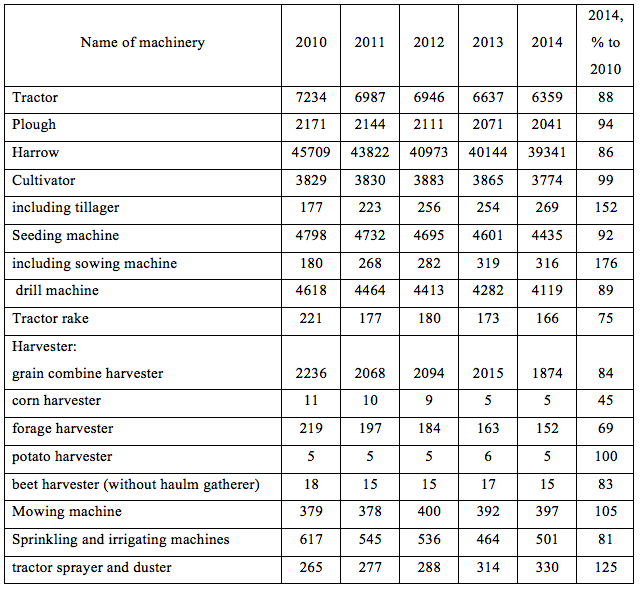

To determine the prospects for the development of regional technical service, it should be analyzed primarily data on the availability of agricultural machinery in the Saratov region of 1 January 2015 (Table 1). Data are presented according to large, medium-sized and small (not micro), agricultural enterprises and agricultural service enterprises [14].

Table 1. Park of main types of machinery in agricultural enterprises, item

For this category of enterprises it can be traced reduction of machinery to 2013: tractors - by 4.2%, grain combine harvesters – by 7.0 %, ploughs - 1.4, seeding machines - by 3.6 %, cultivators - 2.4. But there is also the category of machinery where there is an increase in the amount of items: sprinklers and irrigation machines – by 8.0%, of tractor sprayers and dusters - by 5.1 %.

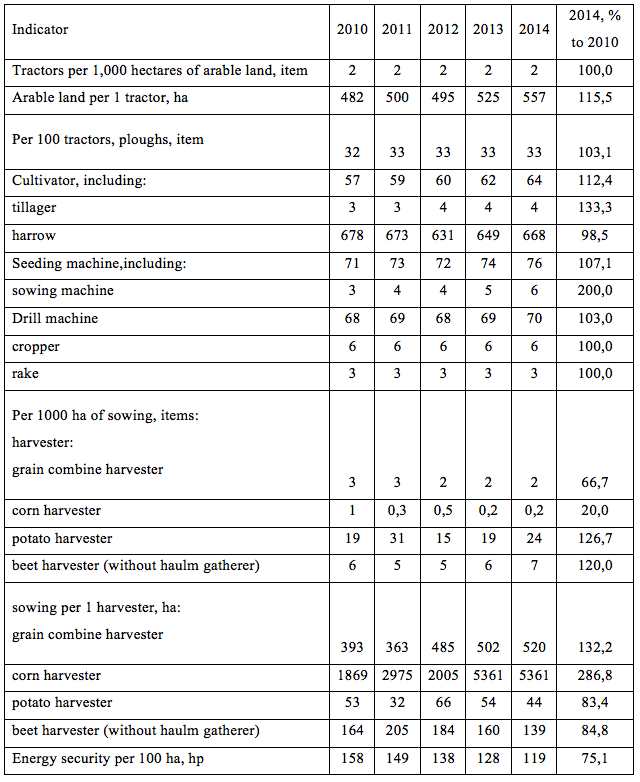

Based on the above data, the provision of agricultural enterprises with agricultural machinery is as follows (table 2) [14].

Table 2. The provision of agricultural enterprises with tractors and harvesters

According to the Table 2, the level of the provision of agricultural enterprises with tractors and harvesters in 2014 is almost at the same level or even increased in relation to 2013, but the index of specific energy supply per unit of cultivated area is decreased.

The current state of technical service enterprises in the region should be considered as the process of agricultural producers provision with machinery, equipment and instruments, as well as the process of effective use of them in good condition during the entire period of operation. It is a prerequisite to fatten the profits and improve the production profitability [15].

The technology of service in the Saratov region is characterized by a considerable distance of the service consumers from the regional dealer center. It negatively affects the efficiency of the repair and maintenance of equipment. In terms of regions with large geographical remoteness of certain areas, this problem can be solved by organizing stations for repair and maintenance machinery, that are located on the service area [6, 11, 16].

The number of necessary stations for repair and maintenance of equipment is a fundamental question addressed in this article, because it affects a set of operational and transport dealer costs.

The theoretical and methodological basis of the research were scientific works, the results of fundamental and applied research of domestic and foreign scientists on the problem under study, as well as the scientific research results and regulatory references. Experiments were carried out in a working environment on service enterprises.

The reliability of the results is confirmed by the use of modern methods of research: monographic, economic and mathematical, statistical, abstract and logical, graphical, and queuing theory.

Service of agricultural machinery and equipment is provided by mobile repair teams, whose work is characterized by the productivity of work execution. However, during periods of energy-intensive field work the number of arrivals may exceed the maximum productivity of service teams that may lead to the queue. No doubt, it can always be avoided by organizing a sufficiently large number of service facilities. But each additional object requires certain operating costs. To determine the optimal number of stations for repair and maintenance of equipment, it is necessary to use mathematical modeling methods [2-6, 13].

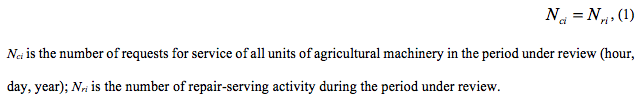

A necessary condition for quality service is the following expression:

Nci is the number of requests for service of all units of agricultural machinery in the period under review (hour, day, year); Nri is the number of repair-serving activity during the period under review.

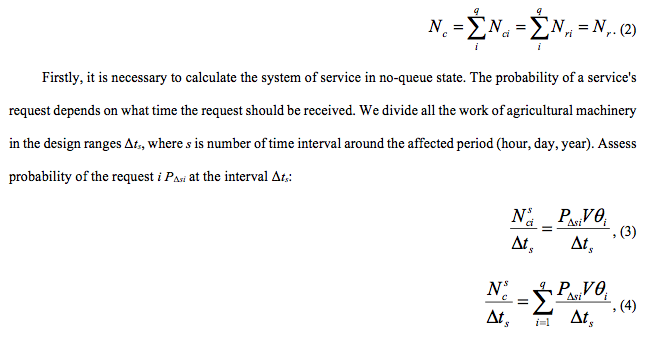

The total number of requests for all types and activity should also be the same:

where V is the total number of serviced equipment, item; θi is the complexity of the request of i type.

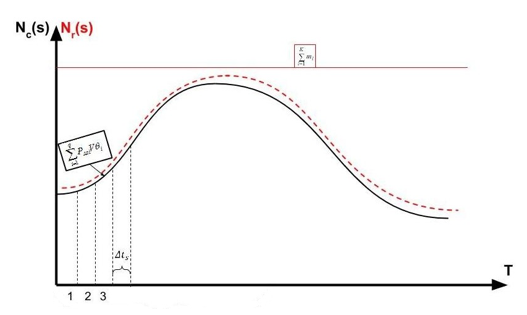

All repair and servicing activities are performed by mobile teams having operating productivity Y, which depends on the shift duration. The calculations assumed that productivity of all teams is the same (figure 1).

Figure 1. The model of service system without queue

The total number of service work performed by all the mobile repair teams during the current time interval is determined by the following formula:

where ml is the number of working crew l; K is the number of stations for repair and maintenance of agricultural machinery.

The formula (5) shows what maximum number of repair and servicing activity can be executed by the system of agricultural machinery service. But working crews do not work more than is needed. Therefore, it is necessary to enter the parameter of the level of brigades’ employment Z, which ranges from 0 to 1.

If the system works without the queues, then:

The formula (8) allows estimating the number of mobile repair teams and stations for repair and maintenance of agricultural equipment for each settlement period s. Accordingly, at the maximum value of the employment indicator (Zs = 1), we obtain the number of stations for repair and maintenance of agricultural equipment, when the service system works without queue.

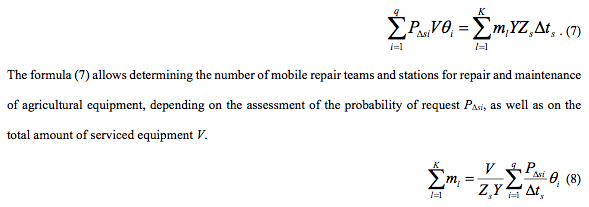

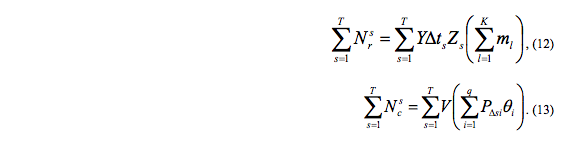

After reduction of the number of the stations for repair and maintenance of agricultural equipment, there may occur time intervals with incoming requests. But, in case of the maximum employment of the stations for repair and maintenance of agricultural equipment, the total load for the entire period under consideration is equal to the incoming requests for repair and servicing activity (Figure 2). This situation is described by the following expressions:

Figure 2. The model of service system with queue

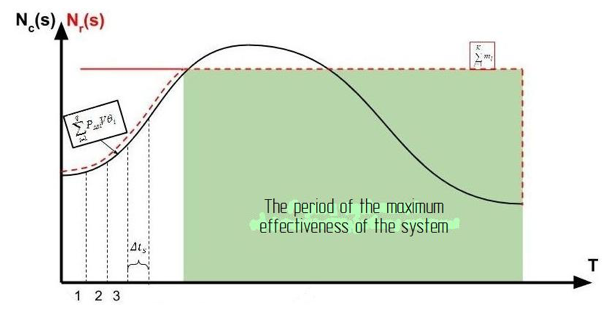

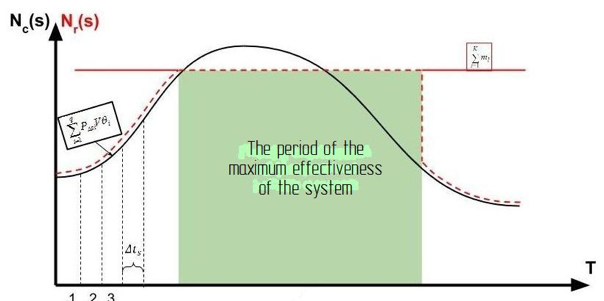

If the waiting time has a fixed value (for example, T = 1 day), the activities of technical service system is characterized by the following schedule (Figure 3).

Figure 3. The model of service system with queue and fixed wait time τ

Define unknown quantity in the formula (11):

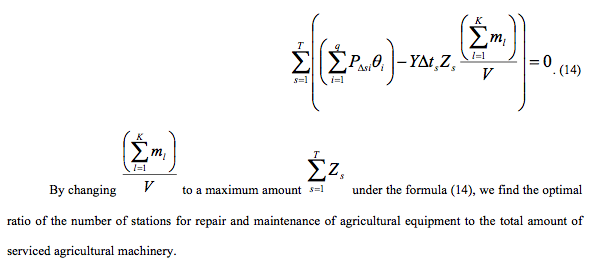

Equating formulas (12) and (13), the following optimization condition can be obtained:

The range of possible repair and servicing activities is characterized by a large difference in labour intensity. To simplify calculations, it is necessary to count average labor intensity θ in order to study only one type of repair and servicing activity with a certain labour intensity instead of the several types of repair and servicing activity.

But in this case the probability of the request of the average labour intensity will be equal to the sum of the probabilities of all service requests:

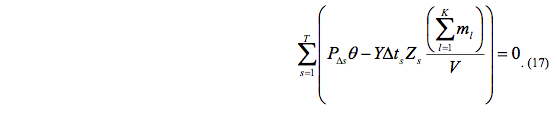

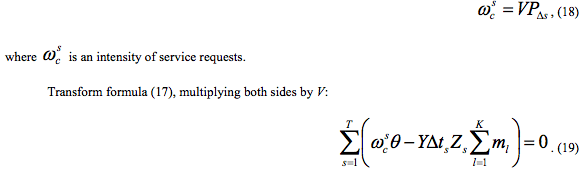

Transforming formula (16), we obtain the following optimization condition:

The actual number of service requests for the estimated time range:

Formula (19) is the final condition for optimization, which allows determining the number of stations for repair and maintenance of agricultural equipment, taking into account the intensity of requests, the complexity of their implementation, the employment of mobile service teams in the reporting period (hour, day, year).

During experimental studies they have been analyzed works on repair and maintenance of tractors MTZ and Kirovets, harvesters ACROS and VECTOR, which are most prevalent in the Saratov region [17-20].

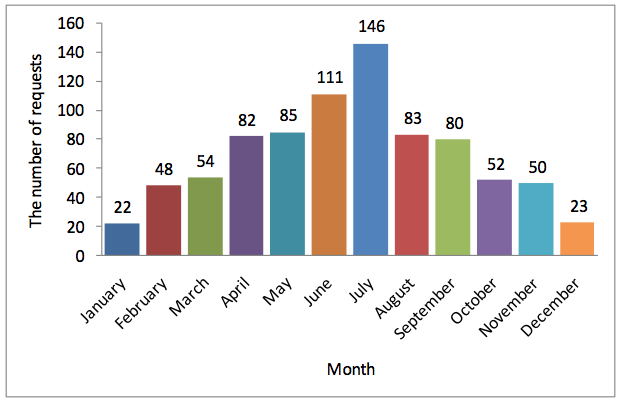

The optimal number of stations for repair and maintenance of agricultural equipment is determined according to requests distribution during estimated time range (a year), Figure 4.

Figure 4. Changes in the number of maintenance and repair by months

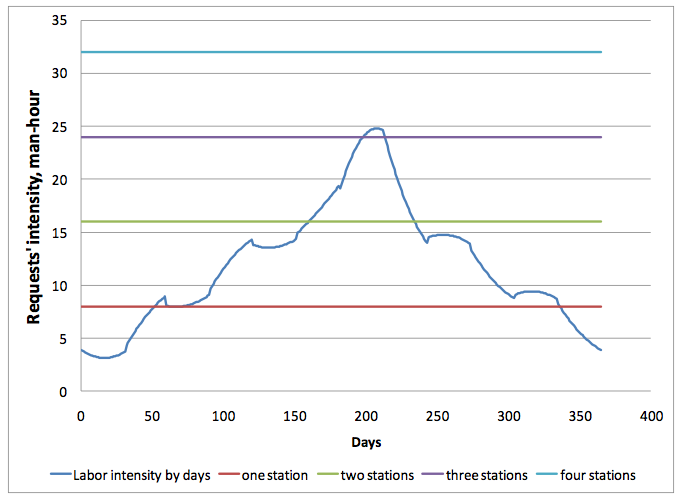

As a result of this problem solution, we obtain a graph of changing in the requests’ quantity for a month (figure 5).

Figure 5. A graph of changing in requests

The horizontal lines on the graph are the length of shifts of mobile work teams, when performing repair and service activity.

As seen in Figure 5, in more detail the organization should consider 2 or 3 points on the repair and maintenance of agricultural machinery (Figures 7 and 8).

As can be seen from Figure 6, it is necessary to study in more details organization of two and three station for repair and maintenance of agricultural equipment (Figures 6, 7).

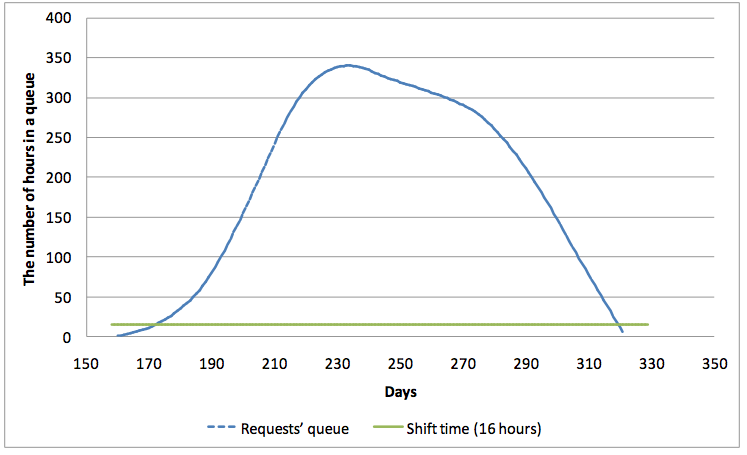

Figure 6. A queue in case of two stations for repair and maintenance of agricultural equipment

Figure 6 shows that all service requests will eventually be performed, but wait for their implementation do not meet the stated criteria. It will lead to the violation of period for field and harvest work that would damage the entire agricultural production [1].

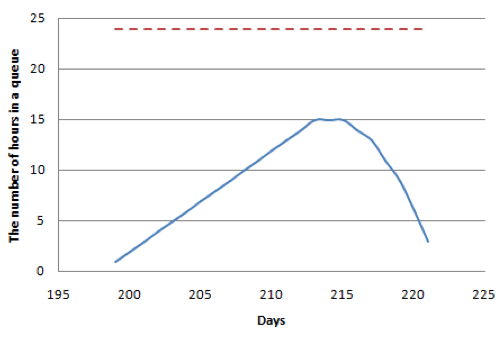

In case of three stations for repair and maintenance of agricultural equipment (Figure 7) a queue does not exceed the daily capacity of three stations. It guarantees progressing of requests during the day. The system of technical service will be able to meet the stated conditions and ensure compliance with the terms of agricultural production.

Figure 7. A queue in case of three stations for repair and maintenance of agricultural equipment

The proposed model can be used by various service enterprises in the development of their branch offices in order to determine their rational amount in regions with a considerable distance of service users that is relevant in Russia. The system of stations for repair and maintenance of agricultural equipment will shorten the distance between consumers and service centers. It will shorten the waiting time and restore the equipment without violation of agronomic terms of agricultural work. This system will reduce the share of transport costs at the service enterprises and optimize the provision of services, as their activities should be not only operational, but also cost-effective.

According to GOSNITI, in case of the rational technical service organization time for maintenance and repair reduces by 8 ... 12%, tractor availability increases by 20 ... 28%, its productivity increases by 34 ... 46% [12].

In conclusion it is necessary to note once again that the system of organization of technical service must provide high availability of machines, the maximum operating time of equipment, good maintenance and operation; interests of agricultural producers; training.

The key to effective use of agricultural machinery is the repair time. Its reduction is a significant reserve for increasing performance of equipment and reduction of production costs.

Modern quality service technology is a complex and high-tech activity. High efficiency of equipment use determines the need for the timely repair and servicing activities that maintain or restore operation of machinery and equipment. Reform of the existing system of organization of the regional technical service will bring it to a whole new level. That is why a massive shift to this kind of service in Russia is inevitable.

1. Saratov State Agrarian University named after N.I. Vavilov, Saratov, Russia. EMail: 216449@mail.ru

2. Saratov State Agrarian University named after N.I. Vavilov, Saratov, Russia

3. Saratov State Agrarian University named after N.I. Vavilov, Saratov, Russia

4. Saratov State Agrarian University named after N.I. Vavilov, Saratov, Russia