Vol. 39 (Number 19) Year 2018 • Page 24

M. ARISTARKHOVA 1; O. ZUEVA 2; M. ZUEVA 3; D. ABZGILDIN 4

Received: 01/02/2018 • Approved: 20/02/2018

ABSTRACT: The article concerns the topic that still occupies interest of many people – the organization of continuous innovations implementation. It contains a presentation of the scientific and methodological approach to the construction of this type of organization. It is proposed to organize the "bank of idea", but for selection, those with the best values of such indicators as labour intensity reduction will be selected for practical implementation; increase in workforce productivity; growth in production volumes; cost reduction; improvement of working conditions. |

RESUMEN: El artículo se refiere al tema que todavía ocupa el interés de muchas personas: la organización de la implementación de innovaciones continuas. Contiene una presentación del enfoque científico y metodológico para la construcción de este tipo de organización. Se propone organizar el "banco de ideas", pero para la selección, aquellos que tengan los mejores valores de tales indicadores como la reducción de la intensidad del trabajo serán seleccionados para la implementación práctica; aumento en la productividad de la fuerza de trabajo; crecimiento en los volúmenes de producción; reducción de costo; mejora de las condiciones de trabajo. |

In this article, the scientific and methodological approach is described not just to implement innovation, but to the organization of continuous innovative development of the enterprise and the management of these processes.

Probably not entirely fair to say that in this perspective, the issues studied were not considered. At least the problems of managing the innovations introduction are reflected in the works of a whole cohort of remarkable economists-L. I. Abalkin, I. A. Baev, V. P. Gorshenin, G. M. Dobrov, I. V. Ershova, N. Novitsky, R.A. Fakhrutdinov, D.S. Lvov, A. A. Rumyantsev, et.al. This list can be continued. However, practically no one was studying the issues of organizing the continuous innovative development of production. The fact is that these problems are complex, multifaceted and multitopic, and to date they have not been completely solved, and each of the named scientists considered the management of the innovations introduction at the angle to which it showed practice. Accordingly, the conducted study of the enterprises of the machine-building complex of the Republic of Bashkortostan convincingly showed the absence on them of the organization system of continuous innovative development of production, which often entails unreasonably rapid obsolescence of innovations, as well as the problems of their "inscription" in the current production process.

It should be noted that the organization of innovation implementation is complicated, therefore the processes accompanying it and connected with the direct development, creation, innovations implementation should be thoroughly studied. The detail degree must be sufficient to distinguish their type, which makes it possible to derive certain regularities. This will be one of the prerequisites for the continuity of innovation implementation .

Accordingly, the purpose of this article is to develop a methodological approach that allows organizing continuous innovative development of production in the enterprise. Achieving this aim required solving the following tasks:

Substantiation of the economic essence of the organizational component of innovation implementation - "bank of ideas";

Systematization of time expenditures on the implementation of processes and procedures related to the organization of innovation implementation;

Justification of the approach to determining the time expenditures on processes and procedures related to the organization of innovation implementation;

Creation of correlation-regression models, allowing determining the time expenditures on the organization of innovation implementation.

All the tasks are solved, and their description is presented in this article.

The results obtained in this study are differ novel.

So, the formed definition of the economic essence of the "bank of ideas" differs by category characteristics such as mobility, structure formation, and obtaining results.

But the composition of the structural elements of the time expenditures on the implementation of processes and procedures related to the organization of innovation, requires the allocation of a specific element - the time of adapting the idea in the production environment.

The developed correlation-regression model made it possible to establish the dependence of the time of adapting the idea in the production environment on the following factors: the direction of the innovation implementation plan, the category of complexity, the worker's qualification, and the size of the production program.

The practical significance of the results obtained in the course of this study is that with their help it is possible to organize continuous innovative development of production at enterprises, and also to manage these processes.

This technique is a way to provide the enterprise-organization with continuous innovation development. With its help, it is possible to present a panorama of a complete set of procedures, the implementation of which will enable the enterprise to implement innovations implementation sustainably and rationally.

The methodology in its own implementation, involves the involvement of all parts of the enterprise, extending to all activities, pre-determining the improvement in the values of performance indicators.

The first stage of the methodology is the formation of a "bank of ideas".

"Bank of ideas" is a specific system of intra-production economic relations that allows you to monitor the necessity of creating innovations in the shortest possible time and with a high degree of efficiency, to form a program of their involvement in the processes of support of production, production and sale of products, which provides the opportunity to competently manage the organization of innovation activities.

The presented definition of the essence of the "bank of ideas" unconditionally raises a number of questions, to which convincing answers must be presented.

First of all, these are characteristics inherent in the "bank of ideas" and revealing its organizational and economic essence.

The fact is that the "bank of ideas" is a mobile category. One can constantly observe how the content of the "bank of ideas" expands - when their new brethren appear and how its content narrows, in cases of practical implementation of some of them.

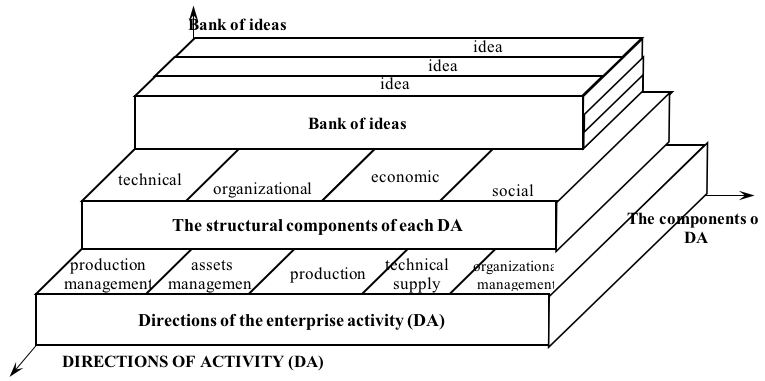

Obviously, the "bank of ideas" is also represented by a certain structure-forming category that combines the possibilities for improving the directions of the enterprise activities (production management, assets management, material and technical supply; organizational management), as well as the components of each direction - technical, organizational, economic, social, with the obligatory provision of these ideas with improving the most important economic indicators - reducing labour intensity, increasing workforce productivity and production volume, reducing costs, increasing profits. The presented structural representation of internal interrelations of the "bank of ideas" is presented in Figure 1.

And another "bank of ideas" is an effective and resultant category that allows you to manage the processes of creating innovations and their implementation and get the planned results.

Thus, the above definition of the essence of the "bank of ideas" highlights that this category is mobile, structuring and efficiently resultant.

The practical embodiment of the "bank of ideas" presupposes the improvement of the results of the activities of all divisions of the enterprise. In addition, the units themselves favourably perceive mutual participation in innovative development, realistically perceiving the positive changes taking place in this process in all components of the production process. This circumstance determines the presence of intra-production economic relations in the study of the essence of the "bank of ideas".

And, finally, that the "bank of ideas" in the formulated definition is represented by a system of intra-production economic relations. This is really so, because its functioning provides for (sometimes simultaneous) interaction of two or more units, as well as their structural elements, in the process of innovations implementation.

Figure 1

System presentation of the creation of the "Bank of ideas"

In its essence, at the first stage, direct collection of ideas is made, their systematization according to the ideas, units, involved in their process of implementation, indicators, the improvement of which is foreseen. Obviously, the technology for forming "bank of ideas" should be identical to the one that accompanies the development of an innovation implementation plan. The difference will be that the plan is formed once a year, and the "bank of ideas" is replenished constantly.

Undoubtedly, the implementation of this stage is associated with the solution of a number of applied problems, including: the form of the document in which the idea should be presented; with whom the idea should or should not be agreed; how these processes should be organized and many other issues that enterprises must solve independently because they reflect the specifics of their activities.

It is assumed that the design solutions must be collected for each technical tool (TT) (length of service, adaptation, type of instrument). This article should be preceded by an analysis of the condition of this TT for ensuring the required growth in workforce productivity. The result of this article is a list of "sick places" of the TS and informing the creative community about them. This article and the collection of proposals for the formation of "reserve" should be carried out constantly.

All the proposals must be formalized in a special "Idea Registration Card", which should contain the following data: the name of the technical means; the general characteristic of the offer; expected economic results of the proposed innovation; time expenditures on the idea.

The second stage consists in choosing from the "bank of ideas" the idea that should be implemented while meeting its specific criteria. As such they can be applied: growth of workforce productivity, time for the implementation of the idea; the cost of the idea implementation.

It should be borne in mind that it is possible that the newly created development is not implemented because it has equal productivity with the tool being replaced.

In order to avoid this, in the technical assignment for the development, it is necessary to indicate a possible increase in the workforce productivity of the equipment that is to be implemented.

The third stage involves determining the time expenditures on the idea implementation and the timing of the beginning of the implementation of the chosen idea.

The solution of this task must begin with the establishment of the "life-span" of the idea-the time-frame for the rationality of replacing the old idea with the new one. As such a term, the factual payback period of a previously implemented idea, an event, a proposal can be adopted, since at that time the cost of this idea implementation was paid off by lowering the cost of production and increasing workforce productivity.

By the time the old idea is replaced, the new one needs to be fully developed. The implementation of the idea is consistently following stages: choice of ideas, design, manufacturing, adaptation. Accordingly, the cycle duration of the idea development (Tidea) will be determined as follows:

Tidea = Tchoice of idea + Tdesign + Тmanufacture + Tadaptation (1)

Where Tchoice of idea is the time expenditures on choosing an idea from the "bank of ideas" (an appropriate algorithm should be developed and approaches to identifying the time expenditures on the choice of the idea should be defined);

Tdesign is the time spent on the idea engineering study (including all stages of the engineering process preparation);

Тmanufacture - time for manufacturing of means of equipment of production process of the design developed at the previous stage, including time for manufacturing of this design;

Tadaptation is the time of adapting the idea (development, design) in production environments.

The most important features of the development time of the idea (Tidea) are:

From all components of formula 1, the latter has a certain novelty, and this circumstance makes it necessary to consider it in detail. Usually, this component is not allocated in the structure of time expenditures, considering that the entire work on its implementation will be completed by making the idea. However, with the increasing complexity, the expansion of the volume of ideas being developed, it becomes necessary to adapt the developed idea to the conditions of its functioning, as well as to familiarize it with it. Otherwise, it is possible to suspend the production process to solve the above problems. Accordingly, the adaptation time (Tadaptation) is defined as follows:

Tadaptation = Tmastering + Tadaptation (2)

where Tmastering is the time to master the skills of practical application of the developed idea (only the worker who exploits this technical tool can swing the idea);

Tadaptation is the time to bring to the organic unity, mastered the vehicle with the system of its functioning.

The provision of continuous innovation development, and especially the management of these processes, requires the development of an approach to determining the expenditures on adaptation, mastering the skills of working with a materialized idea, bringing the created technical means to organic unity with the system of its functioning.

There are several ways to accomplish the solution of an exposed task. The first and most well-known is to normalize the processes and procedures that make up the Tmastering and Tadaptation. Accepting this method for practical implementation, it should be borne in mind that the processes and procedures that are the components of Tmastering and Tadaptation should be broken down into the smallest structural components. Recognizing this fact, it is necessary to recognize the innovative nature of the materialized idea, which can serve as a serious obstacle to detailing the named processes and procedures.

It is possible to try to solve the problem by referring to the method of correlation-regression modelling. The application of this method will require the selection of the composition of factors that affect each of the components of the adaptation time (Tadaptation).

Correlation-regression modelling is one of the ways to solve problems and search for information. It allows determining the joint influence of a set of interrelated and lump-sum characteristics, as well as the separate influence of each feature on the economic phenomenon (process). Due to this type of modelling, it is possible to estimate the degree of interrelation between several characteristics, between the characteristics and the result obtained, and also to simulate the regression equation describing the form of the relationship.

While it is possible to make two assumptions:

1. Development time (Tmastering) is a function of the direction of the innovation implementation plan (P), the category of the work performed complexity (C), the worker's qualification (Q), the size of the production program (PP), etc.

Tmastering = f (P; С; Q; PP ...) (3)

The time to bring the materialized idea to the organic unity with the system of its functioning can be presented as a function of the innovation implementation plan (P), the degree of flexibility in the organization of production (F), and other factors.

Tadaptation = f (P; F; ...) (4)

Having established such dependencies and typing statistical material, it is obvious that it is possible to develop correlation-regression models that allow determining the duration of adaptation time (and by analogy for all components of formula 1).

As applied to this task, several ideas of the enterprise being developed should be considered for constructing a correlation-regression model, and also to identify factors - the extent of their influence on the duration of the development cycle of an idea must be assessed. As such factors are accepted:

the direction of the innovation implementation plan (P);

category of the complexity (C)

worker's qualification (Q);

the size of the production program (PP).

It should be noted that these factors are chosen on the basis that they are all dependent on each other, and their totality affects the length of the adaptation period of the idea.

To the study, 10 ideas were selected that relate to different directions of the innovation plan, with different levels of complexity, carried out by workers of different qualification and different sizes of the production program.

When analysing the dependencies, the following scales were used:

direction of the innovation development plan (P)

category of the work performed complexity (C)

the worker's qualification (Q) indicates the required discharge for the performance of the corresponding task from 1 to 6;

The size of the production program (PP) indicates the number of changes to implement this idea.

After this, the influence of each criterion is determined on the indicator of the adaptation time and an equation is derived that allows determining the duration of the adaptation time (Tadapt.).

Based on the calculations, we will form a general table of indicators with 10 ideas and proposed scales. In addition let's suppose that, within the most significant direction of the innovation development plan (3) with the highest complexity category (3), the maximum of the worker's qualification (3) and the minimum size of the production program (1), the adaptation time will be 4 days, and vice versa in the least significant direction of the innovation development plan (1) with the lowest category of complexity (1), the minimum of the worker's qualification (1), and the size of the production program (9), the adaptation time will be 9 days. Then, the generated data will take the form shown in Table 1.

Table 1

A summary table of the values of factors that

affect the duration of the adaptation time

No. |

|

P |

С |

Q |

PP |

Tadapt, days |

1 |

Idea 1 |

3 |

1 |

6 |

1 |

4 |

2 |

Idea 2 |

1 |

3 |

1 |

9 |

8.83 |

3 |

Idea 3 |

2 |

2 |

4 |

6 |

5.83 |

4 |

Idea 4 |

2 |

2 |

3 |

7 |

6.61 |

5 |

Idea 5 |

1 |

2 |

4 |

6 |

6.07 |

6 |

Idea 6 |

2 |

3 |

2 |

3 |

7.16 |

7 |

Idea 7 |

3 |

2 |

5 |

2 |

4.42 |

8 |

Idea 8 |

3 |

1 |

5 |

1 |

5.08 |

9 |

Idea 9 |

1 |

3 |

1 |

1 |

9 |

10 |

Idea 10 |

2 |

3 |

5 |

8 |

4.30 |

In this case, the correlation dependencies of the adaptation time for each criterion are defined as follows.

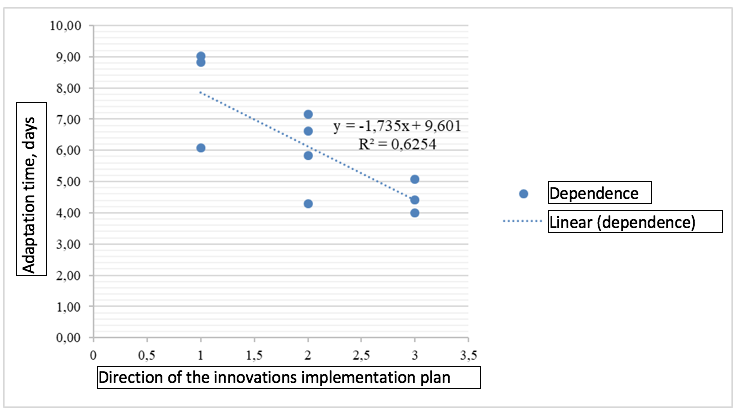

Let's consider the correlation field of the dependence of the adaptation time on the direction of the innovation development plan presented in Figure 2.

Figure 2

Correlation field of the dependence of the adaptation

time of direction of the innovation implementation plan

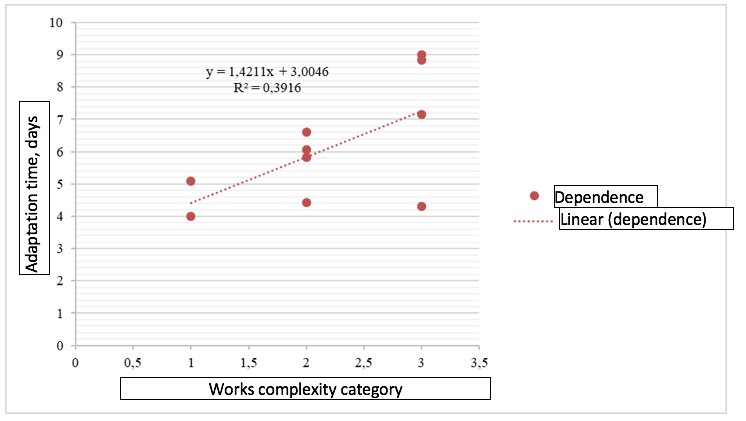

Next, we should construct a graph of the correlation dependence of the adaptation time on the complexity category, which is shown in Figure 3.

Figure 3

Correlation field of the dependence of the adaptation time on the category of the work complexity

After this, we plot the correlation dependence of the adaptation time on the worker's qualification, shown in Figure 4.

Figure 4 Correlation field of the dependence of the adaptation time on the worker's qualification

The performed article makes it possible to develop a schedule of the correlation dependence of the adaptation time on the size of the production program, which is shown in Figure 5.

Figure 5 Correlation field of adaptation time dependency on the size of the production program

After that, it is possible to form the correlation dependency matrix on the basis of the coefficients obtained (Table 2).

Table 2

The correlation dependence matrix

|

Adaptation time |

The direction of the innovation implementation plan |

Category of works complexity |

Worker's qualification |

The size of the production program |

Adaptation time |

1 |

||||

The direction of the innovation implementation plan |

-0.79079 |

1 |

|||

Category of works complexity |

0.62575 |

-0.690066 |

1 |

||

Worker's qualification |

-0.98206 |

0.766064 |

-0.729516 |

1 |

|

The size of the production program |

0.057453 |

-0.501 |

0.52896 |

-0.10132 |

1 |

Regression modelling allows us to consider the influence of the independent variables values on the dependent variable.

After performing the regression analysis of the presented data, the following data were obtained (Table 3, 4)

Table 3

Regression statistics

Regression Statistics |

|

Multiple R |

0.99645492 |

R Square |

0.992922408 |

Adjusted R Square |

0.987260335 |

Standard Error |

0.202194366 |

Observations |

10 |

----

Table 4

Dispersion analysis

df |

SS |

MS |

F |

Significance F |

|

|||||||||

Regression |

4 |

28.67727719 |

7.169319298 |

175.36375 |

1.46751E-05 |

|||||||||

Residual |

5 |

0.204412808 |

0.040882562 |

|||||||||||

Total |

9 |

28.88169 |

||||||||||||

|

Coefficients |

Standard Error |

t Stat |

P-value |

Lower |

Upper 95% |

Lower 95,0% |

Upper 95,0% |

||||||

Intercept |

11.79081 |

0.518039 |

22.76049 |

3.04E-06 |

10.45915 |

13.12247 |

10.45915 |

13.12247 |

||||||

X |

-0.39487 |

0.177418 |

-2.22562 |

0.076585 |

-0.85093 |

0.061202 |

-0.85093 |

0.061202 |

||||||

X |

-0.52629 |

0.173958 |

-3.02539 |

0.029235 |

-0.97346 |

-0.07912 |

-0.97346 |

-0.07912 |

||||||

X |

-1.02312 |

0.096548 |

-10.597 |

0.000129 |

-1.27131 |

-0.77494 |

-1.27131 |

-0.77494 |

||||||

X |

-0.00853 |

0.044233 |

-0.19279 |

0.854707 |

-0.12223 |

0.105176 |

-0.12223 |

0.105176 |

||||||

The generated report allows you to analyse the dependencies of each criterion on the adaptation time.

The received data allow stating the following:

The conducted correlation-regression modelling allows forming the following model of adaptation time:

Тadapt = -0,3949*X1-0.5263*X2-1.0231*X3-0.0085*X4+11.79 (5),

where Т adapt - adaptation time (days);

Х1 is the direction of the innovation implementation plan;

X2 is the category of the works performed complexity;

Х3 – worker's qualification;

Х4 is the size of the production program.

The study (correlation-regression modelling) of the structural components of the adaptation time convinced that the time of mastering (Tmastering) is a function of the direction of the innovation implementation plan (P), the category of the TT works performed complexity (C), the worker's qualification (Q), size of the production program (PP), etc., i.e.

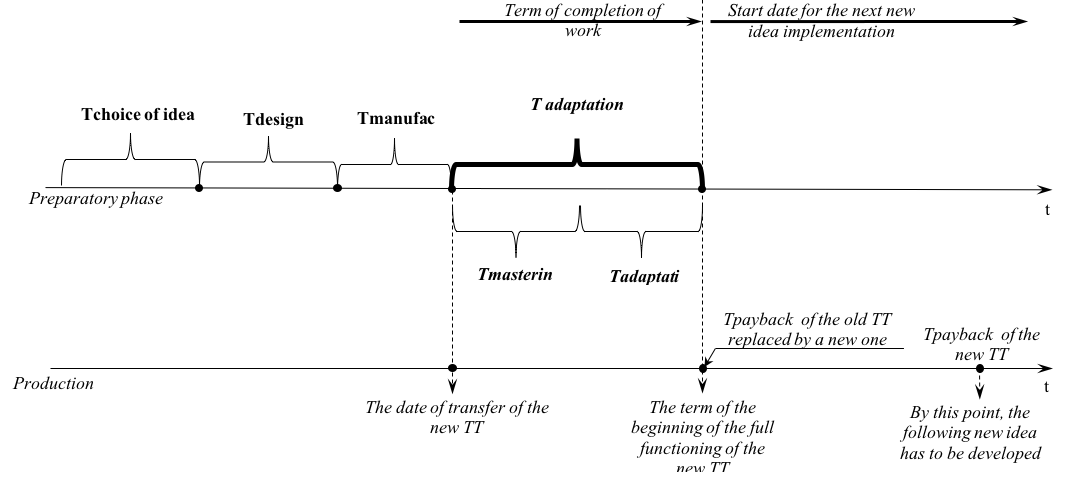

Implementation of the proposal is carried out simultaneously in two areas - production and its preparatory phase, which can be shown in Figure 6.

In this figure, it can be seen that the processes associated with the choice of an idea, its design and technological elaboration by direct manufacturing, as well as adaptation can be carried out in parallel with the previously mastered production.

Figure 6 clearly shows the composition of the stages of work associated with the materialization of the idea. It should be noted that this composition of the stages of work is distinguished by the interconnectedness of the stages, and the stages themselves constitute a vicious circle.

What has been said makes it possible to introduce into the scientific revolution concepts - the cycle of the idea implementation, which is the composition of the stages that reflect the nature of work on the materialization of the idea and is their circuit during any period of time.

And if the notion "the cycle of idea implementation" is introduced, then to realize the management of innovation implementation it will be extremely interesting to know the duration of the cycle of the idea implementation, which is a period of time from the moment of choosing an idea to the beginning of a full-fledged functioning. The model for determining the duration of the cycle of implementation of the idea is represented by the formula 1.

Figure 6

Structural representation of a combination of types of work in the preparatory and production stages

The correlation-regression analysis performed according to the above idea showed that in addition to the presented criteria, other factors not represented in this model also influence the adaptation time. In this connection, of course, there are minor deviations in the adaptation time of the actual and the adaptation time of the planned one.

All this confirms the effectiveness of predicting the adaptation time in the preparatory production phase.

Ensuring sustainable development of production makes the organization of continuous innovative development more and more urgent. Along with this, the relevance of the system approach to the formation of the "bank of innovative ideas" is growing, which represents one of the organizational components of innovation development management, the necessity of its creation being substantiated in the work.

As the performed studies have shown, the "bank of ideas" as an organizational and economic category has a number of specific characteristics, such as systemic, mobility, and structure-forming. In addition, during the study it is justified that it is a system of economic relations that provide organization with an innovative leap forward, in which all structural elements are involved in one form or another. It is assumed that the change in the structural elements of the enterprise as a result of the implementation of a specific idea should be accompanied by an improvement in the values of their final indicators: decrease labour intensity, increase the production volume, increase workforce productivity, increase profits, and reduce costs.

At the same time, the implementation of an idea from the relevant bank is associated with the definition of expenditures and their structural representation, as well as the factors that affect their duration, which to date have not been fully resolved.

In this regard, it is proposed to systematize the structure of the time cost on the implementation of an idea in which it is proposed to emphasize the time for the idea adaptation. It is established that the adaptation time of the idea depends on such factors as the section of the innovation implementation plan, the category of the works performance, the worker's qualification, the size of the production program,

In the course of the study, it was possible to establish the quantitative dependence of the adaptation time on these factors, which is presented

in the formula 5.

Approbation of the proposed approach on the materials of real enterprises showed its reality and the possibility of practical application.

We believe that with the help of the results obtained in this study, enterprises will have an opportunity to organize continuous innovative development of their production. Although, of course, they will also have to face the need to solve a number of particular practical problems that are based on their organizational and economic characteristics. All this, of course, pushes the horizons and opens the way to creativity.

MEDINSKIY, V. G. Innovation management: textbook. M.: Infra-M, 2011.

ABZGILDIN, D.A, ARISTARKHOVA, M.K. The implementation mechanism for socio-economic innovation in a market economy. Actual problems of aviation and cosmonautics. Vol 2, year 2016, number 12, p. 241-244.

ARISTARKHOVA, M.K., ABZGILDIN, D.A. Calculation of innovation production calculation at enterprise. Modern tax system: status, problems and development prospects Materials of the XI International Correspondence Scientific Conference. Year 2017, p. 163-165.

ARISTARKHOVA, M.K., ZUEVA, O.K., ZUEVA, M.S. Simulation of the system of standards of management of innovative product centers. Bulletin of Kazan state technical University n.a. A. N. Tupolev. Vol 73, year 2017, number 1, p. 84-89.

ARISTARKHOVA, M.K., ZUEVA, O.K., ZUEVA, M.S. Formulation of the system of management of innovative activity. Bulletin of Kazan state technical University n.a. A. N. Tupolev. Vol 73, year 2017, number 1, p. 90-95.

ARISTARKHOVA, M.K., ZUEVA, O.K., KARPOV, A. A. Organizational-economic features of management of innovative activity of the enterprise. Bulletin of Kazan state technical University n.a. A. N. Tupolev. Vol 71, year 2015, number 5, p. 71-75.

ARISTARKHOVA, M.K., KUDASHEV, A.R., NIZAMOVA, A. I. Enterprise management: the Gareyev phenomenon. Economy and management: scientific-practical journal. Vol 136, year 2017, number 2, p. 133-139.

BABANOVA, Yu.V., GORSHENIN, V.P. Estimation method of innovative activity of the organization. Herald of the South Ural State University. Series: Economics and management. Vol 281, year 2012, number 22, p. 42-45.

BAEV, I.A., DROZIN, D.A. Modeling of the processes of innovations mastering in the competitive market. Bulletin of the South Ural State University. Series: economics and management. Vol 201, year 2012, number 30, p. 47-49.

BAEV, I.A. Management of innovative processes in an industrial enterprise by business value indicators. Herald of Bulletin of the South Ural State University. Series "Economics and Management". Vol 77, year 2007, number 5, p. 46-53.

LVOV, D.S. Management of scientific and technical development. Problems of theory and practice of management. Year 2004, number 3, p. 63.

1. Department of Tax and Taxation, Ufa State Aviation Technical University Federal State Budgetary Educational Institution of Higher Education, Ufa, Russia. ninufa@mail.ru

2. Department of Tax and Taxation, Ufa State Aviation Technical University Federal State Budgetary Educational Institution of Higher Education, Ufa, Russia.

3. Department of Tax and Taxation, Ufa State Aviation Technical University Federal State Budgetary Educational Institution of Higher Education, Ufa, Russia.

4. Department of Tax and Taxation, Ufa State Aviation Technical University Federal State Budgetary Educational Institution of Higher Education, Ufa, Russia.