Vol. 39 (Number 28) Year 2018 • Page 1

Larisa YURIEVA 1; Elena DOLZHENKOVA 2; Elena KARANINA 3

Received: 12/02/2018 • Approved: 15/03/2018

ABSTRACT: The article presents the authors’ algorithm of innovative attraction assessment of industrial enterprises in Russia, as well as the results of its implementation. We suggest conducting the monitoring of innovative attraction of industrial enterprises based on a system of index numbers, taking into consideration the enterprise environment’s uncertainty level. In high uncertainty conditions, synergetic approach is advisable, while in the medium and low uncertainty conditions complementary approach is more preferable. The index numbers of innovative attraction assessment are achievements in the scientific and technical, human resources activities as well as in the sphere of financial management. The results of our calculations indicate, that the environmental uncertainty level of the industrial enterprises described here in 2012-2015 is high, what implies the necessity of using synergetic approach for managing their innovative attraction. Formation of the flow processes logistic algorithm allows to optimize the technologies, inventory and logistics management and other logistic operations, create highly efficient communicative infrastructure and organizational structure of management and finally decrease the uncertainty level of industrial enterprise environment. Consequently, new additional opportunities for industrial enterprise innovative development appear for the top-management, which proves the necessity and urgency of our research. |

RESUMEN: El artículo presenta el algoritmo de los autores para la evaluación de atracción innovadora de empresas industriales rusas, así como los resultados de su implementación. Se sugiere realizar un seguimiento de la atracción innovadora de las empresas industriales a partir de un sistema de números índices, teniendo en cuenta el nivel de incertidumbre del entorno empresarial. En condiciones de alta incertidumbre, es aconsejable el enfoque sinérgico, mientras que en las condiciones de incertidumbre media y baja es más preferible el enfoque complementario. Los números índices de evaluación de atracción innovadora son logros en las actividades científicas y técnicas, de recursos humanos y en la esfera de la gestión financiera. Los resultados de nuestros cálculos indican que el nivel de incertidumbre ambiental de las empresas industriales descritas aquí en 2012-2015 es alto, lo que implica la necesidad de utilizar un enfoque sinérgico para gestionar su atracción innovadora. La formación del algoritmo logístico de procesos de flujo permite optimizar las tecnologías, la gestión de inventario y logística y otras operaciones logísticas, crear una infraestructura comunicativa altamente eficiente y una estructura organizativa de gestión y, finalmente, disminuir el nivel de incertidumbre del entorno empresarial industrial. En consecuencia, aparecen nuevas oportunidades adicionales para el desarrollo innovador de empresas industriales para la alta dirección, lo que demuestra la necesidad y la urgencia de nuestra investigación. |

Nowadays the innovative vector of development is aimed at stimulation of development of Russian industrial enterprises, whole industries, regions and can make cumulative impact on the potential of Russia’s economy, provide the growth of competitiveness of domestic goods and services, diversification of different kinds of manufacturing, accelerated modernization of technics and technologies, as well as the solution of many social problems. Yet risks and uncertainty don’t allow detecting and predicting innovative activity status at industrial enterprises, industries and regions of Russia exactly. Due to statistical data no conclusions about a remarkable increase of innovative activity of subjects of entrepreneurship could be made (Dolzhenkova et al., 2015). The share of industrial enterprises developing and implementing technological innovations is no more than 10%. The share of innovative production in the total volume of industrial manufacturing production is only 5.5%.

During the last years, the state has actively exercised measures aimed at the development of national innovative system (NIS) of Russia (Smelova, 2012). A number of state institutions of development are functioning, which activate innovative processes and infrastructure potential with the help of state-private partnership mechanisms. Besides, amendments were added to the Tax Code of Russia, aimed at the decrease of the tax duty for innovation –active companies. However, it is too early to talk about the effectiveness of measures of innovative system development in the conditions of turbulence of external and internal environment.

In such conditions for innovative development of an industrial enterprise, the algorithm of monitoring its innovative activity should be formed allowing to take into consideration the environmental uncertainty, changes of status and characteristics of environment in time.

The building of economic patterns in the uncertainty conditions using the games theory and the theory of probabilities was studied by the following scientists:

Borch K.H. (Borch, 2015); Marinacci M. (Marinacci, 2015); Abdellaoui M., Baillon A., Placido L., Wakker P.P. (Abdellaoui et al., 2011); Gilboa, I. (Gilboa, 2010); Li, Ya., Li, Yo., Zhao, Y. (Li et al., 2014) and others.

Research of theoretical aspects of institutional factor analysis in the innovations development was made by such scientists, as: Stroeva O., Lyapina I.R., Konobeeva E.E., Konobeeva O.E. (Stroeva et al., 2015); Wu W., Chen Q., Yu B., He H. (Wu et al., 2008); Zdrazil P., Kraftova I., Mateja Z. (Zdrazil et al., 2016); Zieba M., Zieba K. (Zieba et al., 2014); Rodriguez M. (Rodriguez, 2014) and others.

Interesting approaches of using ABC-analysis are presented in the works of Alsharari N.M. (Alsharari, 2016); Askarany D., Yazdifar H., Askary S. (Askarany et al., 2010). Practical experience of using logistic technology «lean production» is described in the works of Sahno J., Shevtshenko E., Karaulova T., Tahera K. (Sahno et al., 2015, 2014, 2012); Breuer C., Siestrup G., Haasis H.-D., Wildebrand H. (Breuer et al., 2013); Wiengarten F., Fynes B., Onofrei G. (Wiengarten et al., 2013); Paulraj A. (Paulraj, 2011, 2007); Holweg M. (Holweg, 2007); Sakakibara S., Flynn B.B., Schroeder R.G., Morris W.T. (Sakakibara et al., 1997) and others.

Yet, the specifics of theoretical principles and methodical instruments concerning industrial enterprises innovative activity management in uncertainty conditions have not been disclosed fully enough. We would also like to point out, that methodical aspects of innovative attraction assessment have not been studied thoroughly enough, which slows down the process of mass use of principles and methods of administrative analysis for increasing efficiency and quality of decisions taken in the reproduction process innovative segment.

The review of existing scientific works has allowed to summarize the experience gained, to reveal the most characteristic features of industrial enterprises innovative activity development and to notice the absence of complex technologies that allow engaging all the potential at the disposal of an enterprise considering the level of its innovative development.

Hence, it is necessary to clearly determine and differentiate the sphere of use of one or other methods of innovative development in each industrial enterprise functioning conditions, which will allow integral problem-solving in the conditions of changing external and internal environmental factors, giving such solutions a scientific character and avoiding extra social-economic losses.

In the given research the logistic algorithm of flow processes is used, which allows to optimize the industrial enterprise useful resources flow and decrease its environment uncertainty level. The algorithm we offer will allow to receive the highest result when the implementation of rapid changes in the work of industrial enterprises is necessary.

For quantity assessment of industrial enterprise environment’s uncertainty level, we suggest the use of the theory of self-organization of complex well-ordered systems, applying synergetic approach.

The simplest and less time-consuming index of critical (high) level of environment uncertainty is industrial enterprises efficiency Eie as a ratio of net profit to costs. This index number can be calculated using the formula 1:

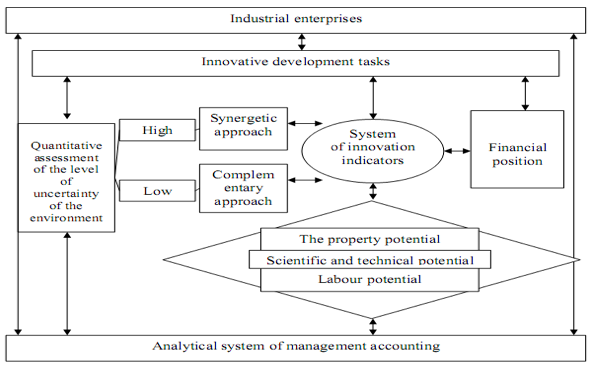

Figure 1

The structure of monitoring industrial enterprise innovative activity

The analysis has shown that the enterprises under inquiry function in high-level uncertainty conditions due to intensive competition, unstable levels of sales and profit (table 1).

The analysis of the above-mentioned enterprises shows abrupt fluctuations of the index of effectiveness for industrial enterprises, calculated from Formula 1. This fact defines the necessity to use synergetic approach to the innovative activity management for the examined enterprises.

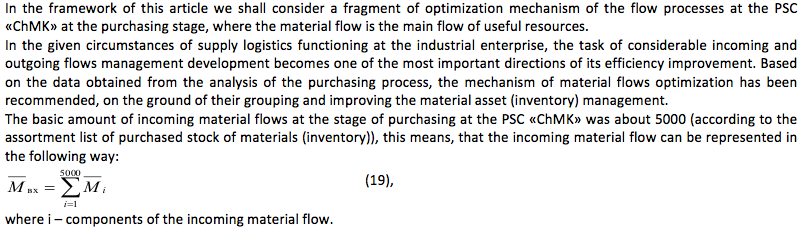

We use logistic algorithm that allows decreasing the industrial enterprise uncertainty level as a result of useful resources flows optimization.

The interconnection between the flows of useful resources in micro-logistics system of an industrial enterprise is shown in Figure 2.

On the basis of the algorithm offered, we make analysis of the useful resources flows structure of the PSC «Chelyabinsk Metallurgical Plant» (PSC «ChMK») with the aim of revealing supporting flows and optimization of total costs of their logistic operation.

PSC «CMK» is one of the biggest iron-and-steel works in Russia, which produces fine and extra-fine steel. The enterprise manufactures wide range of metallurgical products: cold pig iron, steel semi-finished products for further conversion, rolled steel and bar sections produced out of carbon steel, constructional steel, tool steel, corrosion-resistant steel, shaped steel-rolled stock and rail production. PSC «ChMK» is an industrial enterprise being a part of a leading Russian mining and metallurgical company «Mechel».

Table 1

Degree of uncertainty of industrial enterprises environment, %

No. |

Name of the Enterprise |

Period |

|||

2012 |

2013 |

2014 |

2015 |

||

1 |

PSC «Beriev Taganrog Aviation Scientific technical Complex» |

-16,55 |

-9,84 |

11,70 |

-18,01 |

2 |

OJSC «SEGP» |

7,27 |

2,15 |

5,71 |

-3,05 |

3 |

JSC «Research and Production Corporation «UralVagonZavod» |

0,71 |

-8,81 |

-5,83 |

-5,27 |

4 |

PSC «VSMPO-AVISMA Corporation» |

9,90 |

0,24 |

-6,37 |

17,43 |

5 |

JSC «Proletarsky Zavod» |

-3,24 |

-0,02 |

0,16 |

-14,46 |

6 |

JSC «Kurskmedsteklo» |

-18,79 |

-5,00 |

-2,04 |

15,92 |

7 |

PSC «KAMAZ» |

3,61 |

-1,88 |

-1,96 |

-2,37 |

8 |

OJSC «Polymer» |

-0,04 |

4,03 |

-3,04 |

7,68 |

9 |

JSC «Lomo» |

-0,05 |

0,24 |

2,38 |

-5,25 |

10 |

OJSC «Kaluga turbine plant» |

-4,11 |

5,04 |

8,32 |

6,92 |

11 |

OJSC «Zvezda» |

0,04 |

0,69 |

6,02 |

-22,08 |

12 |

JSK «Kuibishevazot» |

-12,60 |

-0,13 |

-2,26 |

7,74 |

… |

… |

… |

… |

… |

… |

34 |

PSC «ChMK» |

-0,22 |

-8,61 |

6,86 |

4,96 |

35 |

PSC «Chimprom» |

29,62 |

-2,54 |

-0,62 |

3,41 |

Figure 2

Useful Resources Flows in the Micro-logistics System of an Industrial Enterprise

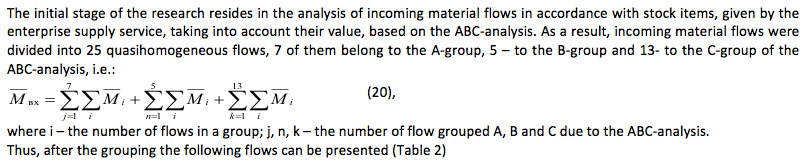

Table 2

Analysis of the Incoming Flows at the PSC «ChMK» as of 01.01.2015

No. |

Name of stock |

Overall value as of 01.01.2015, RUB thousand |

Share in the overall value |

Share in the accrual-based value |

Name of group |

1 |

ALLOY-FREE SCRAP |

2 481 140 |

0,277 |

0,277 |

A |

2 |

PELLETS |

1 096 393 |

0,123 |

0,400 |

A |

3 |

OTHER MATERIALS |

1 073 593 |

0,120 |

0,520 |

A |

4 |

RECYCLED SCRAP AND IRON-AND-STEEL WASTE |

976 722 |

0,109 |

0,629 |

A |

5 |

FERRO-ALLOY |

811 899 |

0,091 |

0,720 |

A |

6 |

SPARE PARTS |

614 828 |

0,069 |

0,788 |

A |

7 |

INTEGRAL IMPLEMENTS IN USE |

392 845 |

0,044 |

0,832 |

A |

8 |

MATERIALS IN TRANSIT |

346 440 |

0,039 |

0,871 |

B |

9 |

FIREBRICKS |

252 567 |

0,028 |

0,899 |

B |

10 |

SINTERING ORE |

197 612 |

0,022 |

0,921 |

B |

11 |

STAINLESS SCRAP B26 |

144 136 |

0,016 |

0,938 |

B |

12 |

FUEL |

128 577 |

0,014 |

0,952 |

B |

13 |

MATERIALS TO CONVERSION |

94 819 |

0,011 |

0,962 |

C |

14 |

ELECTRODES |

82 819 |

0,009 |

0,972 |

C |

15 |

INTEGRAL IMPLEMENTS AT STOCK |

79 609 |

0,009 |

0,981 |

C |

16 |

OTHER RAW MATERIALS |

73 444 |

0,008 |

0,989 |

C |

17 |

EQUIPMENT |

23 952 |

0,003 |

0,992 |

C |

18 |

ALLOYED SCRAP |

18 994 |

0,002 |

0,994 |

C |

19 |

CHARGE MATERIALS (SLAG) |

12 111 |

0,001 |

0,995 |

C |

20 |

NON-FERROUS SCRAP |

11 913 |

0,001 |

0,996 |

C |

21 |

WORKWEAR AT STOCK |

11 796 |

0,001 |

0,998 |

C |

22 |

TIMBER AND CONSTRUCTION MATERIALS |

10 297 |

0,001 |

0,999 |

C |

23 |

WORKWEAR AND FOOTWEAR IN USE |

7 704 |

0,001 |

1,000 |

C |

24 |

PACKING MATERIALS |

1 871 |

0,000 |

1,000 |

C |

25 |

SLAG MUCK |

1 287 |

0,000 |

1,000 |

C |

The next stage aims at optimizing the incoming flow movement based on cutting management costs on the C-group material flow stocks.

Subsequently, the duration of C-group stock rotation is analyzed. The comparison of the results with the limits (regulations) of the rotation indices, specified at the PSC «ChMK» is demonstrated in Table 3.

Table 3

Comparison of Actual and Standard Stock Rotation

Name of Stock |

Actual Rotation (days) |

Standard Rotation (days) |

Standard Rotation Deviation (days) |

MATERIALS TO CONVERSION |

16 |

30 |

-14 |

ELECTRODES |

64 |

20 |

44 |

INTEGRAL IMPLEMENTS AT STOCK |

21 |

30 |

-9 |

OTHER RAW MATERIALS |

9 |

20 |

-11 |

EQUIPMENT |

139 |

150 |

-11 |

ALLOYED SCRAP |

25 |

30 |

-5 |

CHARGE MATERIALS (SLAG) |

4 |

20 |

-16 |

NON-FERROUS SCRAP |

117 |

30 |

87 |

WORKWEAR AT STOCK |

63 |

90 |

-27 |

TIMBER AND CONSTRUCTION MATERIALS |

13 |

30 |

-17 |

WORKWEAR AND FOOTWEAR IN USE |

48 |

60 |

-12 |

PACKING MATERIALS |

144 |

150 |

-6 |

According to the data in the table, duration of stock rotation (in days) of two items: electrodes and non-ferrous scrap, exceeds the set limits and is 64 and 117 days respectively.

Study of stock movements of two selected positions of materials, i.e. “electrodes” and “non-ferrous scrap” as of the end of each month in 2014 and their writing-off (sending) from inventory to production during these months shows unevenness of the material flow movement. Every month there is a 3-4-month supply of non-ferrous scrap and a 2-month supply of electrodes in stock.

Now let us calculate total average monthly cost of inventory availability and writing off stocks of non-ferrous scrap and electrodes, which are available in stock and sent to production. For the calculations we take value of average prices per year and average stock availability (Table 4).

Table 4

Calculation of Total Average Monthly Cost of Availability

and Writing off Non-ferrous Scrap and Electrode Stock

Kind of material |

Average Price for 2014 |

Average Stock Availability as of the End of a Month in 2014 |

Average Stock Discharge into Production per a Month in 2014 |

||

Ton |

Total cost (RUB thousand) |

Ton |

Total cost (RUB thousand) |

||

NON-FERROUS SCRAP |

93,07 |

128 |

11 913 |

33 |

3 071 |

ELECTRODES |

140,37 |

590 |

82 819 |

279 |

39 163 |

IN TOTAL |

|

|

94 732 |

|

42 234 |

The results of our research demonstrate, that discharge of these two positions to production totally is equal to 42 234 RUB thousand in average, while there are stocks at the enterprise warehouses for 94 732 RUB thousand, which indicates a 2-month stock availability (provided, there will be no additional purchase of these materials).

Consequently, we suggest stock decreasing (in these two positions) to the level of monthly rate (as purchasing is done each month, transportation costs will not increase anyway).

In future the enterprise should purchase these materials (non-ferrous scrap and electrodes) according to new established requirement (standard) – in the amount of monthly rate – 33 and 279 ton accordingly with a small reserve (10%) in case of supply disruption (risks are rather low, because the suppliers are reliable according to preliminary estimates).

Thus, monthly procurement established requirement (standard) is equal to the following:

33 · 1,1 = 36 tonnes of non-ferrous scrap and

279 · 1,1 = 307 tonnes of electrodes.

Taking into consideration a 2% - price increase for these materials in 2015, their value is equal to:

93,07 · 1,02 = 94,93 RUB thousand for one ton of non-ferrous scrap

140,37 · 1,02 = 143,18 RUB thousand for one ton of electrodes.

Let us consider how the rotation indices (the length of rotation) of these materials will change (Table 5).

Table 5

Duration of Material Rotation if Purchased in the Suggested Amount

Name of Stock |

Balance on 01.01.15 |

Placing in Property at Stock |

Inventory Discharge |

Balance on 01.02.15 |

Rotation |

||||

tonnes |

RUB thousand |

tonnes |

RUB thousand |

tonnes |

RUB thousand |

tonnes |

RUB thousand |

days |

|

ELECTRODES |

0 |

0 |

307 |

43 956 |

279 |

39 947 |

28 |

4 009 |

3 |

NON-FERROUS SCRAP |

0 |

0 |

36 |

3 417 |

33 |

3 133 |

3 |

28 |

3 |

Thus, the duration of these materials rotation is 3 days, it means that we have managed to decrease it for 61 and 114 days correspondingly.

Consequently, the use of logistics algorithm of flow processes managed to decrease the scalar component of the material flow vector of an enterprise at the purchasing stage, and therefore to decrease the property potential rate, which is one of the components characterizing an industrial enterprise innovative attraction. As a result of our calculations the environment uncertainty level at the industrial enterprise has decreased and in this way, additional opportunities for its innovative development have emerged.

The results of the calculations made in accordance with the author’s algorithm demonstrate, that environment uncertainty level at industrial enterprises in Russia is rather high, and consequently, synergetic approach to innovation activity management at such enterprises is necessary. For decreasing environment uncertainty level, the logistic algorithm of flow processes is proposed.

Such algorithm ensures optimization of technology, inventory and logistics management, product transportation and distribution, workflow rationalization, production premises, warehouses and service rooms design, highly effective communicative infrastructure and management organizational structures creation by means of decreasing total costs on logistics management of industrial enterprises innovative activity.

In our research, the example of optimization of flow processes at the stage of purchasing at the PSC «CHMK» has been demonstrated. Finally, we have conducted the detailed analysis of incoming and outgoing flows of purchasing logistics and have carried out the sequence of decreasing logistic costs on the management of material flow at the stage of enterprise supplying with material assets (inventory).

The demonstrated decrease of costs has made a positive impact on the property potential index at the PSC «ChMK», allowing to implement additional opportunities of innovative development.

This work was supported by the Russian Science Foundation, project no. 15-18-10014 «Projection of optimal socio-economic systems in turbulence of external and internal environment»

Abdellaoui, M., Baillon, A., Placido, L., Wakker, P.P. (2011). The rich domain of uncertainty: Source functions and their experimental implementation. American Economic Review, 101 (2), 695-723.

http://pubs.aeaweb.org/doi/pdfplus/10.1257/aer.101.2.695

Alsharari, N.M. (2016). Results based costing (RBC) system: Questioning the unit of analysis in ABC. Corporate Ownership and Control, 13(2), 587-603.

Askarany, D., Yazdifar, H., Askary, S. (2010). Supply chain management, activity-based costing and organisational factors. International Journal of Production Economics, 127 (2), 238-248.

Borch, K.H. (2015). The economics of uncertainty. Princeton : Princeton University Press, р. 227.

Breuer, C., Siestrup, G., Haasis, H.-D., Wildebrand, H. (2013). Collaborative risk management in sensitive logistics nodes. Team Performance Management , 19(7), 331-351.

Dolzhenkova, E.V., Kazakova, M.A. (2015). The principles of social and economic systems in a complementary and innovative economy. Journal of Economy and entrepreneurship, 11(1), 984-987.

Gilboa, I. (2010). Theory of Decision under Uncertainty. Israel: Berglas School of Economics, Tel-Aviv University,

p. 215.

http://ezproxy.urfu.ru:2117/10.1017/CBO9780511840203

Holweg, M. (2007). The genealogy of lean production. Journal of Operations Management, 25 (2), 420-437.

Iurieva, L.V., Kazakova, M.A. (2014). Infrastructure Monitoring enterprise as a key mechanism for management accounting innovations. «International accounting», Scientific-practical and analytical Journal, 7(301), 14 - 25.

Kazakova, M.A., Dolzhenkova, E.V. (2015). Complementary and synergistic approaches to the innovative development of socio-economic systems. Journal of Economy and entrepreneurship, 10(2), 559-563.

Li, Ya., Li, Yo., Zhao, Y. Fang Wang Which Factor Dominates the Industry Evolution? A Synergy Analysis Based on China's ICT Industry. Inzinerine Ekonomika-Engineering Economics, 25(3), 273-282.

Marinacci, M. (2015). Model uncertainty. Journal of the European Economic Association, 13(6), 1022-1100.

Paulraj, A. (2011). Understanding the relationships between internal resources and capabilities, sustainable supply management and organizational sustainability. Journal of Supply Chain Management, 47 (1), 19-37.

Paulraj, A., Chen, I.J. (2007). Strategic buyer-supplier relationships, information technology and external logistics integration. Journal of Supply Chain Management, 43 (2), 2-14.

Rodriguez, M. (2014). Innovation, Knowledge Spillovers and High-Tech Services in European Regions. Inzinerine Ekonomika-Engineering Economics, 25(1), 31-39.

Sahno, J., Opik, R., Kostina, M., Paavel, M., Shevtshenko, E., & Wang, Y. (2012). Knowledge Management Framework for Production Route Selection in Manufacturing Enterprises. In 8th International DAAAM Baltic Conference Industrial Engineering, 567–572.

Sahno, J., & Shevtshenko, E. (2014). Quality Improvement Methodologies for Continuous Improvement of Production Processes and Product Quality and Their Evolution. 9th International DAAAM Baltic Conference Industrial Engineering, 181–186.

Sahno, J., Shevtshenko, E., Karaulova, T., Tahera, K. (2015). Framework for continuous improvement of production processes. Inzinerine Ekonomika-Engineering Economics, 26(2), 169-180.

Sakakibara, S., Flynn, B.B., Schroeder, R.G., Morris, W.T. (1997). The impact of just-in-time manufacturing and its infrastructure on manufacturing performance. Management Science, 43 (9), 1246-1257.

Smelova, O.V. (2012). National Innovation System of Russia: Problems and development. Problems of modern economy, 3(43), 16-19.

Stroeva, O., Lyapina, I.R., Konobeeva, E.E., Konobeeva, O.E. (2015). Effectiveness of management of innovative activities in regional socio-economic systems. European Research Studies Journal, 18(3), 63-76.

Wiengarten, F., Fynes, B., Onofrei, G. (2013). Exploring synergetic effects between investments in environmental and quality/lean practices in supply chains. Supply Chain Management, 18(2), 148-160.

Wu, W., Chen, Q., Yu, B., He, H. (2008). Effects of management innovation on telecommunication industry system. WSEAS Transactions on Systems, 7 (5), 455-465. http://www.wseas.us/e-library/transactions/systems/2008/27-137.pdf

Zdrazil, P., Kraftova, I., Mateja, Z. (2016). Reflection of Industrial Structure in Innovative Capability. Inzinerine Ekonomika-Engineering Economics, 27(3), 304-315.

Zieba, M., Zieba, K. (2014). Knowledge Management Critical Success Factors and the Innovativeness of KIBS Companies. Inzinerine Ekonomika-Engineering Economics, 25(4), 458-465.

1. Urals Federal University, Ekaterinburg, Russia. e-mail: lv_yurieva@mail.ru

2. Urals Federal University, Ekaterinburg, Russia. e-mail:lenag1981@mail.ru

3. Vyatka State University, Kirov, Russia