Vol. 39 (Number 48) Year 2018. Page 24

Rafael Guillermo GARCÍA Cáceres 1; Carmen Lucía VERGARA 2; Oscar Orlando ORTIZ Rodríguez 3

Recibido: 06/06/2018 • Aprobado: 29/08/2018 • Publicado 29/11/2018

ABSTRACT: The present paper characterizes the supply and value chains of the potato agribusiness sector at the world level, emphasizing the Colombian case. Based on previous agribusiness chain characterization works, the methodology describes the economic, social and environmental features of the chains in question, in order to facilitate the decision-making process. The most important agent of the studied chains was found to be the producer, who operates the production stage, which, in turn, takes place during the upstream phase. However, this is the weakest stage of the chain, and the one that absorbs all the uncertainty of its operation. |

RESUMEN: Este artículo caracteriza las cadenas de abastecimiento y valor del sector agroindustrial de la papa en un contexto mundial, con énfasis en el caso colombiano. Basada en trabajos previos de caracterización de cadenas agroindustriales, la metodología describe los rasgos económicos, sociales y ambientales de las cadenas en estudio, para facilitar sus procesos de toma de decisión. Se encontró que el agente clave de estas cadenas es el productor, quien opera el eslabón de producción de la papa, lo cual, a su vez, tiene lugar durante la fase upstream. Sin embargo, este eslabón es el más débil de la cadena, y el que absorbe la incertidumbre de su operación. |

Within the framework provided by CONPES document 3527 of 2008 (National Productivity and Competitiveness Policy), low levels of innovation in production systems are mainly evident through scarce research and adoption of new technologies. In part, this is so because of cultural resistance to said adoption, particularly on the part of small producers, which adds up to a series of factors that result in low productivity and competitiveness of the chain in its upstream phase (Barrero, 2012).

As part of the general agribusiness program of Colombia, potato constitutes a key staple for the country and the world, because of its elevated and increasing demand. This particular chain presents several problems regarding its productivity, sustainability and competitiveness. In Colombia this sector has been significantly affected by free trade agreements, guild weaknesses and the price of supplies, on which this crop is heavily dependent. This, in turn, negatively affects the welfare of a significant number of rural families who live directly on potato production, especially in the departments of Boyacá, Cundinamarca and Nariño. These people have long been looking for a solution to this adverse situation, partly through agreements with the State, which are aimed at the establishment of favorable policies for the sector.

According to COLCIENCIAS (2005), three strategies have been proposed to improve the productive efficiency of this crop, namely chain articulation, cost reduction, and the strengthening of the primary sector through applied research on biotechnology and conventional plant breeding techniques.

The research priorities of the potato agribusiness chain have to do with soil and water integrated management, economic and environmental assessment of farming practices, environmental impact on the ecosystems where the crop is grown, and application of plant breeding techniques (Ministerio de Ciencia y Tecnología, 2012).

The aforementioned considerations indicate both the need and the opportunity to add value to this agribusiness chain. In this sense, the National Agenda for Science, Technology and Agricultural Innovation (Agenda Nacional de Ciencia, Tecnología e Innovación Agropecuaria – ANCTIA), which instructs on the application of new technologies for the development of agriculture, provided the basic guidelines for the development of the present project. Thus, its main objective was "to characterize the supply and value chains of the potato agribusiness in Colombia" (Bonilla et al., 2009, p.17), which is aligned with the series of Colombian agribusiness chain characterization studies that set the course of action for the current methodological framework.

The Supply Chain (SC) concept has been explained as "a multi-agent organization that seeks to meet the demands of the final customer by effectively coordinating its information, product and financial resource flows, which link the supplier to the customer’s customer (García-Cáceres et al., 2013). As to other definitions, the supply chain has been assumed to “cover all activities related to the flow and transformation of goods, from the raw material stage to the end user one, as well as the related information flows" (Ballou, 2004). Just as well, it has been regarded as “a set of three or more entities that are directly related according to descending and ascending flows of products, services, financial resources and information, from the primary production source to the final customer" (Mentzer, 2001, cited in Ballou, 2007).

The Value Chain (VC) concept was developed by Michael Porter in 1986, who stated that it "provides a way to classify the processes of a company in two groups, namely primary and support processes". Within the group of primary processes, we can find logistics, operations and marketing. For their part, support processes include administration and technology, human resource and procurement management. In this way, value is added as each process becomes more productive.

The VC can be understood as a network of alliances between independent companies, aimed at creating strategies that benefit all members, thus allowing the whole group to manage the flow of goods and services.

In the context of agri-food chains, the notion of "strategic alliances" implies that the association is planned in advance by a group of people collectively undertaking activities that they cannot perform individually. The result is a "competitive intelligence", which collects and shares information that cannot be accessed independently" (Holmund and Futon, 2009).

Some key organizational considerations to build a successful VC include information flow management, performance evaluation, the establishment of common goals, the existence of tangible benefits for all members involved, and the creation of trust and cooperative work relationships (Holmund and Futon, 2009).

Porter defines the value chain as "the sum of the benefits perceived by the customers, minus the costs they incur in order to acquire and use a product or service" (Porter, 1998). In the current work, the VC is assumed to be the set of actions, functions or techniques that add value to a product.

According to previous works on the cocoa (García-Cáceres et al., 2014), coffee (García-Cáceres and Olaya, 2006) and oil palm (García-Cáceres et al., 2013) agribusiness chains, the current characterization methodology comprised the following steps:

Step 1. Assessing the national and global production of the potato SC: a search was conducted in secondary information sources such as FEDEPAPA (Federación Nacional de Cultivadores de Papa, which stands for “National Federation of Potato Growers”), FAO (Food and Agriculture Organization) and TRADE MAP.

Step 2. Identifying the Colombian agents of the SC, according to data provided by the National Ministry of Agriculture, which are, in turn, mainly obtained from FEDEPAPA.

Step 3. Description of the local SC, based on primary and secondary information. This was done in order to include the views of potato growers, provided that the production step is considered to be the backbone of the chain.

Step 4. Description of the global supply chain, mainly based on secondary information sources, but not neglecting the data provided by the producers.

Step 5. Diagnosis and conclusions about the SC.

At this step, surveys were conducted to obtain information from primary sources, which in the present case corresponded to potato growers of the departments of Boyacá and Cundinamarca. For such purpose, the reference background was provided by the work of Willersinn et al. (2015), who studied the quantity and quality of food losses along the Swiss potato SC, by means of a stepwise investigation. Quantitative data were obtained from field trials; structured interviews with wholesalers, processors and retailers; and consumer surveys in combination with a 30-day long study. This led to evaluating both fresh potato production and processed potato losses. Secondary information sources include documents, journals and websites, which facilitated the technological, institutional (law and business policy) and economic characterization of the studied supply and value chains.

Global market

Potato is considered to be one of the most important staples of the world, due to its nutritional value and high starch content. The China is the largest producer worldwide, with a>90-million-tons yearly harvest, followed by India, Rusia, Ucrania and the USA (see Table 1).

Table 1

Major worldwide potato producers

Country |

Yearly tons |

China India Federación de Rusia Ucrania The United States of America |

99,065,724 43,770,000 31,107,797 21,750,290 19,990,950 |

Source: Adapted from Trademap

Table 2 shows the largest potato importers of the world: Belgium, with 2,001,183 tons, followed by the Netherlands, Spain, Italy, Germany and the United States.

Table 2

Major potato importers around the world during 2016

Importers |

Imported amount (yearly tons) |

Belgium The Netherlands Spain Italy Germany United States of America Portugal |

2.001.183 1.788.643 728.936 636.686 592.485 511.311 442.216 |

Source: Adapted from Trademap

China ranks first among harvested areas, and is also one of the major importers (see Table 3).

Table 3

Major potato harvested areas

Position |

Country |

Ha |

1 2 3 4 5 |

China India Federación de Rusia Ucrania United States of America |

5,812,865 2,130,000 2,030,858 1,311,600 407,810 |

Source: Adapted from Trademap

The continents with the largest worldwide production are Asia (190,516,292 tons), Europe (117,555,648 tons), and America (42,592,735 tons) (see Table 4):

Table 4

Worldwide potato production

Region |

Tons |

World Asia Europe America Africa Oceania |

376,826,9679 190,516,292 117,555,648 42,592,735 24,501,902 1,660,390 |

Source: Adapted from FAO

The Netherlands, France and Germany are potato exporters, while The Netherlands and Germany are also large worldwide producers (see Table 5).

Table 5

Potato exports during

Country |

Millions of US$ |

Netherlands France Germany Canada China Belgium United States of America Egypt United Kingdom Spain |

$805,356 $603,406 $349,234 $227,849 $226,453 $210,198 $204,423 $162,009 $148,755 $136,229 |

Source: Adapted from Trademap

Domestic market

On average, potato production represents 32% of the Colombian transitory crop yield. This is, in fact, one of the products of greater consumption in this country, especially in high Andean regions, where it constitutes the basic staple due to its easiness of access and relatively low price (Rojas & Durán, 2011). The potato market in Colombia is considered to be inefficient due to its high levels of intermediation, low or zero value added, absence of quality standards, permanent price fluctuation due to the difficulty to maintain a steady supply, dispersion of producers and consumers, storage difficulties and poor promotion of the product. The market is, for the most part, oriented to direct fresh consumption, while a minimum percentage of the total national production is industrially processed (Fedepapa, 2014).

According to the National Agricultural Survey (Encuesta Nacional Agropecuaria – ENA), carried out by the DANE (2016), out of 3,034,023 tons harvested in Colombia in 2016, 90% came from the departments of Cundinamarca, Boyacá and Nariño (see Table 6).

Table 6

Major potato harvested areas

Department |

Harvested Area(Ha) |

Production (Tons) |

Yield (Tons/Ha) |

Cundinamarca Boyacá Nariño Antioquia Cauca Norte de Santander Santander Tolima Valle del Cauca Caldas Risaralda Total |

58,082 45,620 38,304 5,575 5,159 2,986 2,628 1,807 291 102 39 160,593 |

1,207,193 886,597 684,981 109,285 70,983 27,362 39,166 11,669 1,969 711 106 3,034,023 |

20.7 19.4 17.9 19.6 13.8 9.2 14.9 6.5 6.8 6.9 2.8 138.3 |

Source: Adapted from DANE

Table 7 shows a positive percent index of yield variation across harvested areas in Colombia, indicating a cyclic behavior with a negative trend from 2012 to 2014.

Table 7

Yield variation across potato cultivated areas in Colombia

YEAR |

YIELD (Ton/Ha) |

2008 2009 2010 2011 2012 2013 2014 |

18.8 19 19.1 20.6 21.4 20.9 20.4 |

Source: Adapted from Ministerio de Agricultura y Desarrollo Rural

The cities with higher prices per kilogram of potato are Medellín, Sincelejo and Manizales. Due to logistic costs, other Colombian cities maintain lower and less changeable prices (Trujillo et al., 2013).

SC agents in Colombia and description of the local potato SC

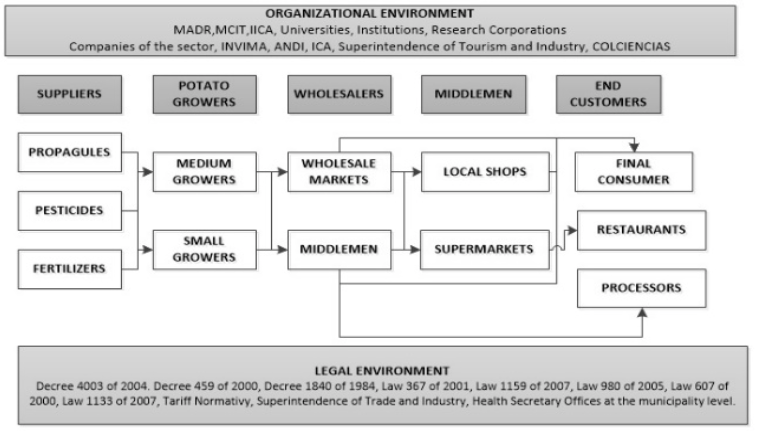

The stages identified for the Colombian potato SC are the following: Provision of supplies, potato production, wholesales, retailing, and purchase by the end customer.

These stages are also related to each other, in such a way that these interactions make the product reach the end customer. Figure 1 shows the mentioned stages, interactions and stage components:

Figure 1

Potato supply chain

Source: The authors (2016), based on data provided by the Colombian Ministry of Agriculture

(Ministerio de Agricultura de Colombia) http://www.minagricultura.gov.co. Accessed February 15, 2015.

Below is a detailed description of Figure 1:

The first stage of the SC corresponds to the provision of propagules, fertilizers and pesticides, the latter being intended to control general plague problems, as is the case of chafer grubs, among others. Supply quality must be certified by the Food and Drugs Surveillance Institute (Instituto para la Vigilancia de Medicamentos y Alimentos - INVIMA). These products must be developed in certified laboratories, thus visibly exhibiting the dates of fabrication and expiration. This stage helps assuring that the final product fulfills all the necessary conditions when it enters the market.

The elements involved in this stage mainly have to do with the products offered by suppliers, each of which is presented below:

The recommendations of FEDEPAPA (2015) with respect to propagules indicate that they should be very healthy (thus free of pests and diseases) and uniformly sized (medium to large), since they offer better resistance to drought. The propagules should ideally produce multiple sprouts, which allows better stem establishment, uniform emergence of the crop and high yield potential. The following aspects should be considered:

● The propagules should not have bruises, black spots or any external or internal lesion.

● They must be purchased from a reputable supplier with proven track record.

● Propagule viability constitutes a fundamental factor which, under optimum sowing conditions, allows the vegetative development of the plant.

● The propagules must have a germination point that allows the plant to sprout and develop properly.

Table 8 specifies the offer of potato propagules by FEDEPAPA in April of 2016.

Table 8. Available potato propagules in April 2014

Variety |

Number of bags |

Category |

Harvest date |

Rubí Ciacol Capiro Ica Unica Pastusa Suprema |

45 2901 198 2193 |

Certified Certified Certified Certified |

August November November November |

Source: Adapted from Fedepapa

It is recommended to apply a fertilization plan based on soil analysis results, nutritional requirements by variety and expected yields. It is advisable to apply soluble sources supplemented with properly composted organic fertilizers to contribute to soil moisture retention. Just as well, foliar fertilization with potassium and micronutrients is advisable. When plants show water deficiency symptoms or frost damage, foliar applications with sugar are recommended (Fedepapa., 2015).

The agents involved in this stage are:

❖ FEDEPAPA: Supplier of propagules and phytosanitary management services

❖ Fertilizer and pesticide producing laboratories

❖ INVIMA: responsible for issuing sanitary registers.

The classification of potatoes in the market is carried out according to the following characteristics: Color; skin texture, number of eyes, tuber form, outbreak characteristics and harvest, among others.

As to its nutritional value, potato contains three parts of water to one part of starch, carbohydrates, proteins, and lipids. Protein, fiber and vitamin contents are low. The tuber is cholesterol free, contains no sodium, is a good source of vitamins C and B6, and provides dietary fiber.

The potato types that best respond to market requirements are Tocarreña and Pastusa, due to versatility of consumption. For its part, yellow diploid potato (locally known as papa criolla) is sometimes precooked and frozen to be exported.

The second stage is mainly operated by the producers, who are mostly small and some medium scale ones. Potato production in the country is led by Cundinamarca and Boyacá, with a sustained production over the last four years.

Potato is a transitory crop, yielding two yearly harvests. In Colombia, its commercial production is carried out between 2,000 and 3,000 m asl. Although the areas of optimal production in terms of the quality and quantity of the product are located between 2,500 and 3,000 m asl, there are two areas of marginal production. This is so because of limiting factors that correspond to pests and diseases in the case of mild climates (between 1,500 and 2,000 m asl), and to frost in high altitudes ranging from 3,500 to 4,000 m asl. Ninety percent of potato commercial production takes place on sloping land, while 10% is done on flat, mechanizable soils (CEVIPAPA, 2015, p.2).

This stage must ensure the following functions:

● Guaranteeing the delivery of the harvest on the established dates

● Producing high quality potato

● Establishing coordination with suppliers and wholesalers

● Setting the selling price.

As the center of the SC, this stage determines its entire dynamics. It is conditioned by the price, amount, variety and quality of the product.

Potato producers can be classified in three groups: small, medium and large (Table 9).

Table 9

Classification of potato producers

Type of producers |

Description |

Small

Medium

Large |

This category is considered to represent 95% of potato growers, who carry out their activity in extensions smaller than three ha. These farmers make up 7.2% of all potato growers in the country. The activity takes place in extensions larger than 3 ha and smaller than 10 ha. Representing 1.3% of the country´s producers, they cultivate >10 ha land plots. |

Source: Adapted from DANE

Most potato growers are small farmers who practice contour plowing. When the slope is lower than 25%, mechanical traction is used for plowing. In steeper areas, the soil is tilled either manually with a hoe, or resorting to oxen, for which a moldboard plow is used (García-Cáceres et al., 2014).

The sowing is done before the beginning of the rainy season, in order to take advantage of rainwater for the germination and development of the crop. The propagules that are most often used are selected from crops growing in the same farm where the planting is going to take place, or in neighboring localities of higher altitude. The task of covering and fertilizing the propagules is done manually with a hoe. General use equipment such as back sprayers or tractors are employed for the maintenance of the crop. In general, the sprayers are not calibrated; “[they] use only one type of nozzle for all products, and no protection garment" (Ministerio de Agricultura y Desarrollo Rural, 2005a, p. 36).

The agents that intervene at this stage are:

❖ Producers from different departments around the country.

❖ Farmers, who prepare the land for the planting.

❖ Several worker categories, who are in charge of soil fertilization, fumigation, harvest, tuber classification and packing, and trading the product with the wholesalers.

In most cases, the family group is in charge of these tasks, wherein child labor is quite common.

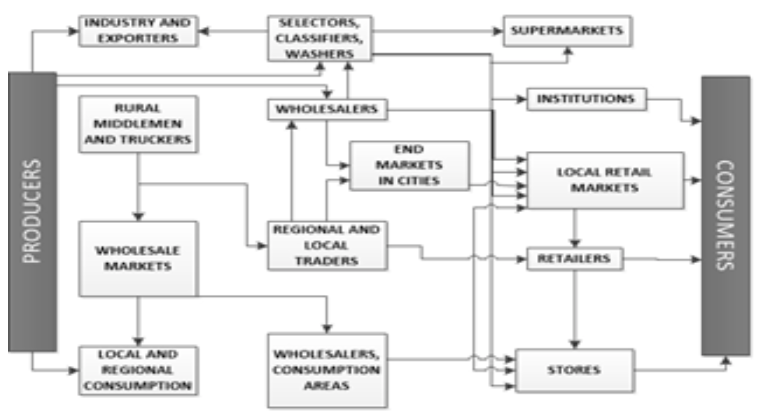

The third stage corresponds to wholesales. Figure 2 illustrates the structure of the Colombian potato market, according to Fedepapa.

The main task at this stage is to distribute the product in large amounts at the national or international levels. Wholesalers usually have direct contact with the producers, in order to avoid an increase in the marketing costs, which is common when there are intermediaries.

Figure 2

Potato marketing structure

Source: The authors

❖ The agents of this stage correspond to wholesale markets and intermediaries.

Intermediaries are responsible for negotiating with the producers. As marketers, they run potato warehouses and sell the product in small places such as intermediate cities, but usually not in wholesale markets. These intermediaries can be identified as middlemen.

Retailers are those who buy the product from wholesalers to supply their businesses and reach the end customer. Retailers sell at a higher price than wholesalers because they take greater risks, since they do not receive a completely fresh product and must handle higher logistic costs.

Their functions include:

● Delivering a good quality product.

● Defining the selling price to the final consumer.

● Articulating with wholesalers and intermediaries and, of course, with the final customer.

❖ Superstores, which are actually retailers.

❖ Small grocery stores

❖ Neighborhood stores

❖ Potato street vendors, who announce the product in popular neighborhoods.

❖ Wholesalers.

This stage is characteristically featured by retailers, who maintain a direct relationship with the end customer. They buy the product in local markets and sell it at a higher price, by pounds, kilos and arrobas.

The fifth and final stage takes the product to the end customers, who are the majority of the Colombian population, including some small and medium processing industries that obtain by-products such as homemade potato fries.

❖ Food shops

They are those who purchase raw or partially processed potato, as is the case of French fries. They correspond to ordinary and specialized restaurants, roasted chicken stops, and shopping centers.

❖ Processors

These include "large, medium and small companies that elaborate a properly packed, ready-to-eat product" (García-Cáceres et al., 2013). Processors correspond to companies like “Yupi” and “Frito-lay”, among others.

❖ Housewives

This agent is the one that most frequently purchases the product (three to four times a week), mainly for family consumption purposes.

❖ Restaurants

Depending on the size of the market and the type of customer they serve, restaurants purchase the product in neighborhood stores or wholesale markets.

Value chain of the potato agribusiness sector in Colombia

In order to characterize the VC of the potato agribusiness sector in Colombia, the two largest producers at the national level, namely the departments of Cundinamarca and Boyacá, were analyzed in detail. In order to determine the agents of this agribusiness chain, a primary information survey was conducted with producers and other key agents, priorly identified based on secondary data. The information was collected from the two largest potato producing municipalities of each of the studied departments (as identified by the DANE). The survey instrument in question is presented in Appendix A.

The results of the surveys are broken down by municipality. The number of respondents followed the distribution detailed below:

Tabla 10

Distribution of the surveyed farmers by rural divisions (veredas) of the two studied municipalities.

YEAR |

YIELD (Ton/Ha) |

Puente Boyacá Montoya Matanegra Ventaquemada total Bosavita Chinquirá Soatama Villapinzón total |

212 91 79 382 200 40 133 373 |

Source: The authors

Potato production constitutes the first stage of the SC (upstream phase) and the basis for its operation. In order to estimate the value added by the farmers at this stage, a survey was conducted, containing 14 questions. This instrument was applied by visiting the farms of 755 potato producers of the municipalities of Ventaquemada (Cundinamarca) and Villapinzón (Boyacá). The choice of the two studied municipalities and their rural divisions (veredas) was not random, since they both contribute the largest potato production in their respective departments. The rural divisions were chosen according to productivity data provided by the mayoralties at the time of the arrival of the research team to the municipality.

Table 11 presents the sequence of cropping activities performed by the potato growers of the departments of Boyacá and Cundinamarca, together with the economic percentage represented by each stage.

Table 11

Indicators

Stage |

Activity |

Description |

Economic percentage |

Production |

Selection of propagules for sowing |

Pastusa |

17.9% |

Diacol Capiro (R12) |

|||

Tocarreña |

|||

Criolla |

|||

Other |

|||

Land tilling |

Plow |

34.9% |

|

Propagule sowing |

Labor |

26.0% |

|

Fertilizers |

Pest control |

21.2% |

|

Harvest |

Labor |

Harvesting potatoes from the soil |

43.1% |

Potato selection |

Selection of potatoes for sale |

45.0% |

|

Transportation |

Transport to local towns |

11.9% |

Prepared by the authors. 2016

As it can be observed in Table 11, the harvest conveys the most significant losses for potato growers, because of the selection process, which is highly labor consuming. This stage includes product transportation to cities like Tunja or Bogota, which also implies an elevated cost for the farmer.

Propagule selection is an important decision that strongly affects the cost of the production stage, since it determines the pests that are likely to attack the crop. The production stage contributes the largest value added to the SC and VC

Following methodology by Porter (1998), the key indicators and possible impacts of the upstream phase of the Colombian potato VC were identified. The indicators in question were developed with the aid and participation of the community, specifically potato growing leaders. This is also intended to facilitate a more active participation of the individuals in the association processes involved in their relations with governmental institutions, all of which facilitates their decision - making processes. The indicators proposed are detailed below:

Table 12

Indicators

Type |

Indicator |

Impacts |

Economic |

Production and loss of investment (percentage) |

Decreased life quality of potato growers |

Loss of land |

||

Cessation of potato production |

||

Sales |

Debts with suppliers |

|

Inability to pay loans |

||

Social |

Technical assistance level |

Crop quality drop |

Lack of pest management knowledge |

||

Scarce crop modernization |

||

Demand for the product |

Loss of customers |

|

Decrease in new product development |

||

Environmental |

Hydric resource contamination level |

Health problems in rural communities |

Soil exploitation level |

Loss of soil |

|

Erosion |

Source: The autors

These indicators should be regularly measured by potato growers in their rural division and municipal associations, in order to administrate continuous value improvement within the SC (Carrillo et al., 2002).

The measuring specifics of each of the proposed indicators, as well as their corresponding targets, goals and formulas are presented in Table 13.

Table 13

Management standards of the indicators

Indicator |

Type |

Target |

Frequency |

Danger |

Precaution |

Goal |

Formula |

Production and loss of investment (percentage) |

Economic |

Reducing production losses in order to ensure continuity of cropping activity |

Six monthly |

90% |

85% |

95% |

Total investment / Total loss (percentage) |

Sales |

Economic |

Gradually increasing sales in order to reduce unnecessary debts |

Six monthly |

80% |

85% |

90% |

Debt value / Net profit |

Technical assistance level |

Social |

Achieving greater presence of specialists in potato cultivation |

Six monthly |

80% |

85% |

90% |

Number of potato growers / Delivered technical assistance |

Demand for the product |

Social |

Increasing domestic potato demand by businesses |

Six monthly |

80% |

85% |

90% |

Total production / Demand for the product (percentage) |

Hydric resource contamination level |

Environmental |

Reducing environmental impact on water resources. |

Annual |

50% |

40% |

70% |

% of contamination / Permitted levels |

Soil exploitation level |

Environmental |

Reducing soil erosion and ensuring its useful life through training on land use |

Annual |

60% |

40% |

80% |

% of soil erosion / Possibilities of soil recovery |

Prepared by the authors

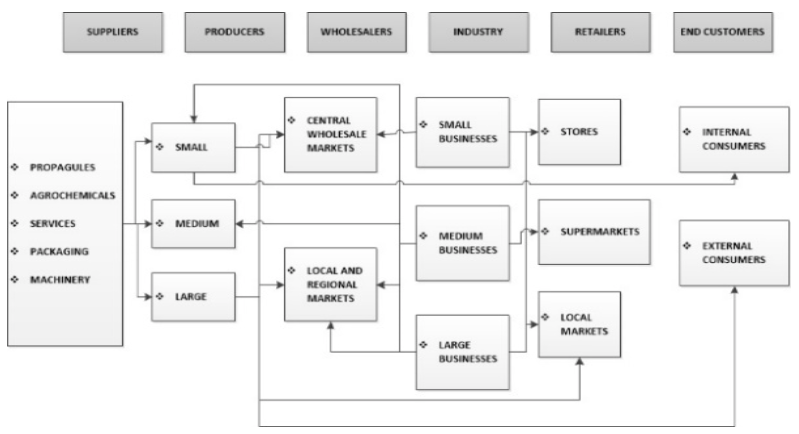

The value chain constructed from the collected information is summarized in Figure 3.

Figure 3

Value chain

Prepared by the authors

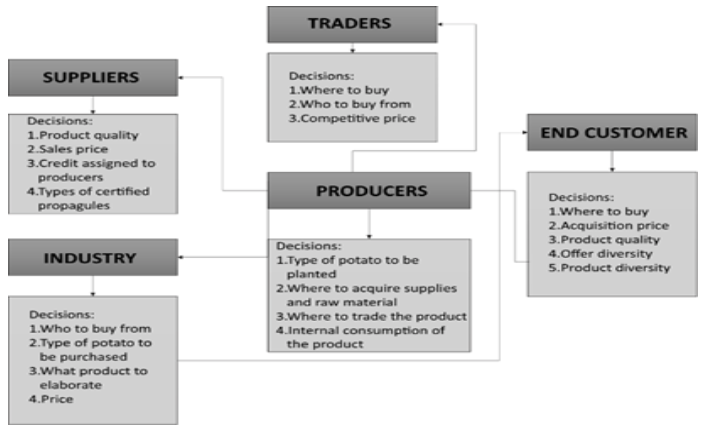

Based on the above, Figure 4 illustrates the relation between the other two stages, in the framework provided by Carrillo et al. (2002).

Figure 4

Connections between the stages of the value chain.

Prepared by the authors. 2016

The decision on the type and amount of potato that is to be planted exerts a significant influence on the other stages. This has to do, on the one hand, with the connection between the offer of a particular potato type, its sales price and the availability of its propagules. On the other hand, there is a considerable influence on plant health, because not all potato varieties are prone to the same diseases, nor they require the same supplies.

Potato growers have large crop losses, not only due to lack of modernization of their crops, but also to weather conditions. In spite of this, potato production in the country corresponds to the needs of the people. However, if the planting conditions and the training of the farmers to face agroecological variations and pests that attack the crop can be improved, domestic production might increase, which, in turn, would level the field to export the product.

The obtained primary and secondary information allowed demonstrating the existence of added value on the part of suppliers of inputs and raw materials, which are sold in local towns. This is so because producers prefer to pay a slightly higher price to avoid having to travel long distances to source raw materials and supplies, which could imply higher costs. This also shows the difficulties involved in the upstream phase when it comes to establishing community partnerships that allow obtaining better prices for volume purchases when intermediation is reduced.

Potato cultivation in Colombia is labor intensive and scarcely modernized. The profits are marginal and dependent on associated costs which, in turn, hinge on technological level, land fertility and location, and potato variety. In this sense, there are areas in which cultivation is very difficult to sustain due to the elevated risk posed by frost and the large number of natural enemies of the crop.

The variable “client” is perhaps the one that exerts the most influence on the VC, because the entire production process is aimed at customer satisfaction. The specifics of potato demand (which, in turn, are aligned to a particular type of consumer) determine the variety to be planted. For example, the chip industry, which requires a durable tuber that neither blackens when fried nor has an elevated sugar content, usually resorts to varieties like ICA Única. However, it has become clear that this type of potato is not regularly planted, probably because this industry looks for specialized bulk suppliers with whom they establish medium and long term contracts. Traditional producers usually aim at mainstream markets, and thus sow those potato types that are easy to trade, as is the case of varieties Pastusa, DIACOL Capiro (R12) and Tocarreña, which are preferred by end customers such as restaurants, housewives, neighborhood stores and both wholesale and retail markets.

As shown in the survey (Appendix B), one of the factors that determine potato cultivation losses are weather problems such as changing temperatures and frost. Willersinn et al. (2016) studied the economic impact of environmental factors in Swiss potato crops. These authors state that losses can be reduced by changing consumption and product fermentation practices. In Switzerland, these losses are 8 to 42 times higher than in the rest of the world.

The present study involved the use of primary and secondary information sources. The primary source corresponded to a survey applied in the municipalities of Ventaquemada and Villapinzón, which belong to the departments of Boyacá and Cundinamarca, respectively. This article presents new research perspectives addressing the solution of the problems of the sector. In this regard, the lack of decision-making support mechanisms for potato growers was observed. Just as well, the difficulty to establish adequate partnership limits the access to supplies and the development of sustainable production alternatives. Finally, it is worthwhile noting that the deficient modernization, support mechanisms and definition of the specific roles of the agents involved at each stage also affect the potato growing activity.

A research perspective is to find the constrast between methodologies to characterize supply chain (Lambert & Enz., 2016), (Salazar et al., 2012) and (García & Ospina., 2017). Also, to characterize other Agricole commodities supply chains.

We want to express our gratitude for the support provided by potato growers and civil authorities of the areas visited in Boyacá and Cundinamarca. Without their help it would not have been possible to develop this project. This Project is founded for the UPTC through GRANT DIN 03-2018

Ballou, R. (2004) Logística. Administración de la Cadena de Suministro. 5th edition. Mexico: Pearson Educación, 2004. 816 p.

Barrero, O. (July 23, 2012). Programa Nacional Ciencia, Tecnología e Innovación Agropecuarias. Accessed at: http://dmastec.blogspot.com/

Bonilla, M., Cardozo, F., & Morales, A. (2009). Agenda prospectiva de investigación y desarrollo tecnológico para la cadena productiva de la papa en Colombia con énfasis en papa criolla. Bogota: Corporación Colombiana de Investigación Agropecuaria (Corpoica).

Carrillo, M.P., Fiorillo, G.R. García-Cáceres, R.G. (2002). Modelo Analítico de Administración de cadenas de abastecimiento en PYMES. Revista Ingeniería y Universidad 6(2), 119- 135

CEVIPAPA. (2015). Centro virtual de investigación de la cadena agroalimentaria de la papa. Accessed at: http://www.cevipapa.org.co

Consejo Nacional de Política Económica y Social. (2008). Documento CONPES 3527. Política nacional de competitividad y productividad. Bogota: Consejo Nacional de Política Económica y Social.

Consejo Nacional de Política Económica y Social. (2009). Documento Conpes 3582 DNP. Bogota: Consejo Nacional de Política Económica y Social.

COLCIENCIAS. (2005). Plan estratégico del Programa Nacional de Ciencia y Tecnología Agropecuaria 2005 – 2015. Bogota: COLCIENCIAS Colombia.

DANE. (2016). Encuesta Nacional Agropecuaria ENA. Bogota: DANE.

García-Cáceres, R.G., Núñez, A.L., Ramírez, T.A., Jaimes, S.A. (2013). Caracterización de la fase Upstream de las Cadenas de Valor y de Abastecimiento de Palma de Aceite en Colombia. DYNA. 80(179) pp. 79-89.

García-Cáceres, R.G., Perdomo, A., Ortiz, O.O., Beltrán, P., López, K., (2014). Characterization of the supply and value chains of Colombian cocoa. DYNA 81(187) pp. 30-40.

García-Cáceres, R.G., Olaya, E.S. (2006). Caracterización de las cadenas de valor y abastecimiento del sector agroindustrial del café. Cuadernos de Administración. 19(31), 197 – 217.

García-Cáceres, R.G., Ospina-Estupiñan, H.R (2017). Continuing evolution of model free. Evolution of trade zones in the world with an emphasis in the Latin American DYNA. 84(202) pp. 221-229

FAO. (2016). Organización de las Naciones Unidas para la Alimentación y la Agricultura: Retrieved February, 2018, from http://www.fao.org/colombia/es/.

Fedepapa. (2014). Estado del mercado de la papa. Revista Papa. No. 31 March, 2014, 34-38.

Fedepapa. (2015). Official website of FEDEPAPA. Accessed at: http://www.fedepapa.com/?page_id=1894" \h

Holmlund, M. & Fulton, M. (2009). Networking for Success: Strategic Alliances in the New Agriculture. Centre for the Study of Cooperatives, University of Saskatchewan.

Lambert, D.M., & Enz, M.G., Issues in Supply Chain Management: Progress and potential. (2016). Industrial Marketing Management, http://dx.doi.org/10.1016/j.indmarman.2016.12.002

Ministerio de Ciencia y Tecnología. (2012). Hacia una Agenda Nacional en Ciencia, Tecnología e Innovación. Ciudad Universitaria D.F.

Ministerio de Agricultura y Desarrollo Rural. (2005a). La cadena de la papa en Colombia una mirada global de su estructura y dinámica 1991-2005. Observatorio Agrocadenas Colombia. Documento de Trabajo No. 54., 1-32.

Porter, M. (1998). Competitive Advantage of nations: Creating and Sustaining Superior Performance. New York: First Free Press Edition.

Rojas, R., & Duran, D. S. (2011). Efecto del secado por microondas sobre el color de la papa criolla (Solanum phureja). @limentech, Ciencia y Tecnología Alimentaria, 104-114.

Salazar, F., Cavazos, J., & Nuño, P. (2012). Strengths and weaknesses of SCOR model: Supply chain biodiesel castor. IIE Annual Conference. Proceedings, 1-10. Recuperado de https://bdbiblioteca.universidadean.edu.co:2237/docview/1151083737?accountid=34925

TRADEMAP (2016). Estadísticas del comercio para el desarrolo internacional de las empresas: Retrieved February, 2018, from https://www.trademap.org/Index.aspx

Trujillo, Y., Villamizar, N., & Duran, D. (2013). Caracterización de la polifenoloxidasa en tres variedades de papa (Tuberosum solanum L.) mínimamente procesada y su incidencia en el color. @limentech, Ciencia y Tecnología Alimentaria, 5-12.

Willersinn, C., Mack, G., Mouron, P., Keiser, A., & Siegrist, M. (2015). Quantity and quality of food losses along the Swiss potato supply chain: Stepwise investigation and the influence of quality standards on losses. Waste Management 46, 120–132.

Willersinn, C., Möbius, S., Mouron, P., Lansche, J., & Mack,G. (2016). Environmental impacts of food losses along the entire Swiss potato supply chain: Current situation and reduction potentials. Journal of Cleaner Production 30, 1-11

1. School of Industrial Engineering. Universidad Pedagogica y Tecnologica de Colombia. rafael.garcia01@uptc.edu.co

2. School of Industrial Engineering. Universidad de Pamplona. carluvegal@hotmail.com

3. School of Industrial Engineering. Universidad de Pamplona. oscarortiz@unipamplona.edu.co