Vol. 40 (Number 20) Year 2019. Page 11

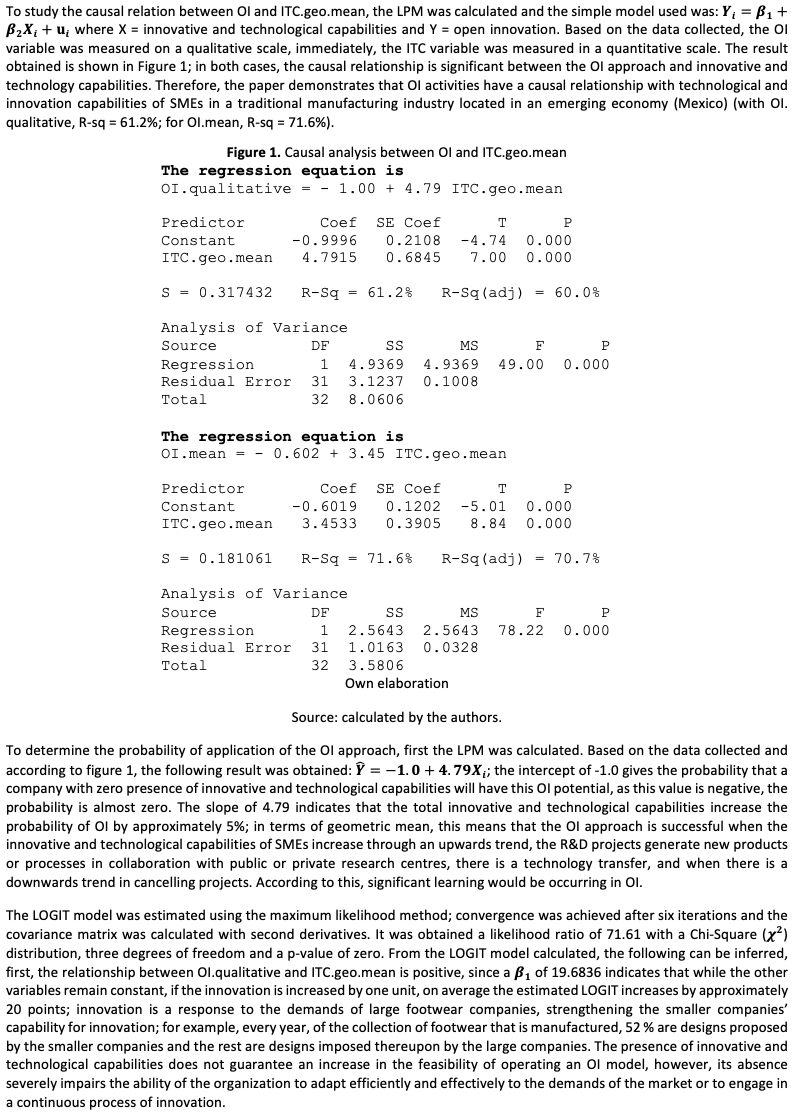

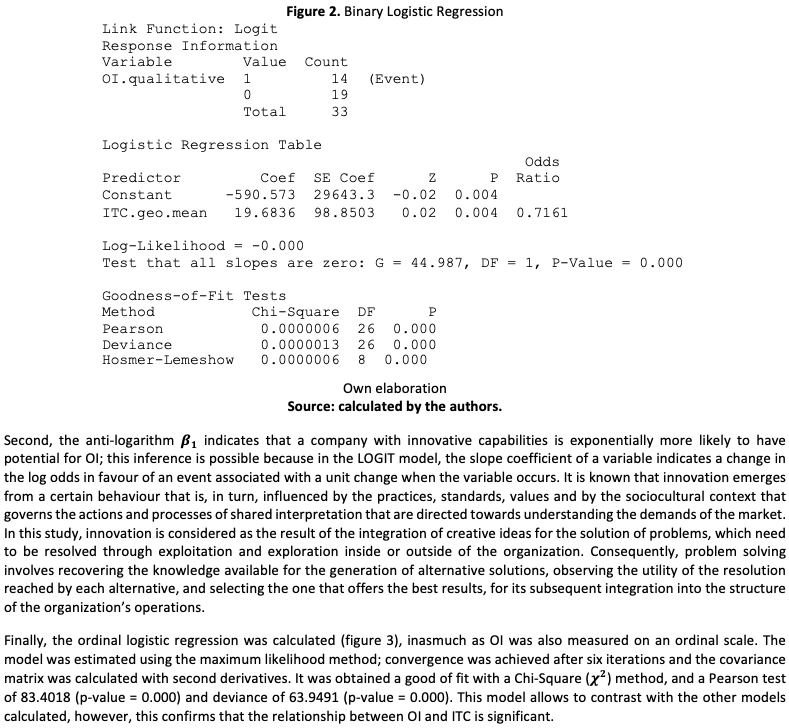

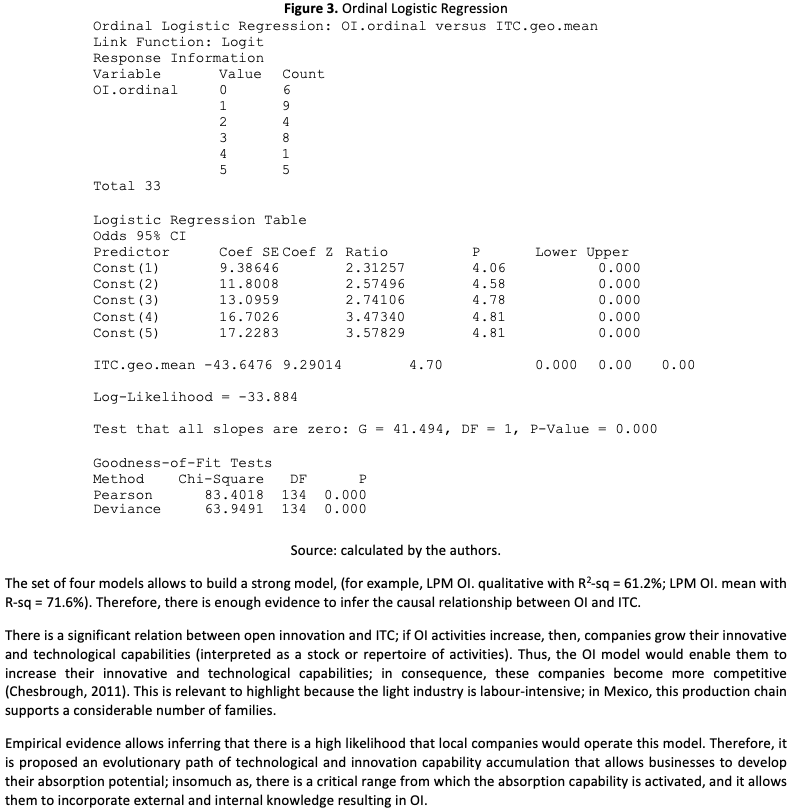

ÁLVAREZ-CASTAÑÓN, Lorena del C. 1; LÓPEZ-LIRA, Alfonso 2 y ESTRADA-DOMÍNGUEZ, Jesús E. 3

Received: 06/03/2019 • Approved: 03/06/2019 • Published 17/06/2019

ABSTRACT: The aim of this paper was to analyse the dimensions of the open innovation (OI) and the technological and innovation capabilities of Small and Medium-sized Enterprises (SMEs) in a traditional manufacturing industry. A qualitative response regression analysis based on an approach of qualitative comparative analysis was conducted implying a cross-sectional study of a sample of 33 SMEs in Guanajuato, Mexico. Results obtained in these SMEs can lead to an overview of OI in a traditional industry such as shoe manufacturing industry. |

RESUMEN: El objetivo de este documento fue analizar las dimensiones de la innovación abierta (OI) y las capacidades tecnológicas y de innovación de las pequeñas y medianas empresas (PYME) en una industria manufacturera tradicional. Se realizó un estudio cualitativo a través de una regresión que implicó un estudio transversal de una muestra de 33 pymes en Guanajuato, México. Los resultados están restringidos a un contexto específico; sin embargo, se presenta una visión general de OI en una industria tradicional. |

Numerous studies have proven that innovation is the main determining factor in the success of a company; it is usually the culmination of a rigorous process of research and development (R&D) and the appropriation of strategies to create value for shareholders (Kutvonen 2011; Shim, Park and Choi 2018; Yuandi 2012). Innovation is essential for companies that seek to develop sustainable competitive advantages to manage increased competition resulting from globalization of markets, speed of technological change, information technology, and knowledge economy (Agénor and Dinh 2013; Kutvonen 2011; Lin 2017; Witt 2017).

The companies that comprise the footwear production industry are not exempt of the competition and the globalization; although these are local companies, whose activities are centred in a closed environment, these compete with imported footwear in the domestic market, and with high added value footwear when these export to other countries. Therefore, footwear importance in the social-productive sectors of state are very significant because a number very relevant of companies in Guanajuato belong to this industrial sector (CICEG 2017). According on Secretary of Economy (2018), the footwear sector is considered a light industry. This industry is made up of more than seven thousand footwear manufacturing local companies, highly concentrated in only a few states; Guanajuato represents 68%, Jalisco 18%, Mexico City and its metropolitan area 13% and the rest of the Mexican Republic 1% (INEGI 2014). The industry annually produces around 260 million pairs of footwear while domestic consumption is estimated at 321 million pairs, exportation at 26.35 million pairs and importation at 88.09 million pairs (CICEG 2017); this industry generates 579,000 jobs in Mexico and 275,000 jobs in Guanajuato, approximately (CICEG 2017; INEGI 2015).

This paper proposes a theoretical-methodological framework that can improve the understanding of OI of SMEs in a traditional manufacturing industry located in an emerging market economy that it is catalogued as non-innovative; also, the building of an index through geometric mean is a methodological novelty. The results show that these firms can innovate in the different stages of their productive process in an OI model, therefore, the companies in these countries can use this approach at different levels of openness and collaboration.

Technological capabilities allow to generate and to manage improvements in processes and organization of production, products, equipment, and engineering projects as to create new technologies and develop new products and processes (Chesbrough 2017; Gassmann et al. 2010). Innovation capability can be defined in terms of the continuous transformation of knowledge and ideas into new products, processes, and systems for the benefit of the firm and its stakeholders.

According to the Schumpeterian standpoint, Innovation constitutes a base process of capitalism, besides being a crucial factor for the success of companies where new technologies replace old ones through what he called creative destruction (Agénor and Dinh 2013; Lin 2017; Witt 2017); from this point of view, the base types of innovation are: new industrial organization, new product, new production method, new market, new raw materials (Berglund and Sandström 2017).

Innovation involves a set of knowledge flows and stocks accumulated by scientific and technological activities in companies, which increase their intellectual heritage (Gassmann et al. 2010; Wolff 2010) and enhance their competitiveness.

Open innovation is facilitated when companies are agglomerated in clusters; this has been shown in studies of six clusters of SMEs in Austria, Germany, and Switzerland, where OI has helped them grow steadily and sustainably (Gassmann et al. 2010; Schroll and Mild 2011). OI is characterized by the organizations’ alliances, usually with collaboration networks or clusters, to integrate new knowledge and experience (Huizingh 2011; Wang and Zhou 2012). Several studies showed that footwear companies in Guanajuato are agglomerated (Alvarez and Cruz 2016; Unger, Flores and Perez 2014), so the latter argument suggests that the OI approach is feasible for the case of shoe manufacturing companies in Guanajuato (Alvarez and Cruz 2016).

OI allows to strengthen innovative capability of companies (Chesbrough 2011; Wang and Zhou 2012), to facilitate the integration of new technologies and the automation of production processes (Gassmann, Enkel and Chesbrough 2010; Marilungo, Coscia, Quaglia, Peruzzini and Germani 2016). The use of information technologies (IT) is an essential action for OI because it facilitates communication to increase the constant flow of ideas that allows the improvement of internal processes, the offer of products and services to new markets, the reduction of operating costs (Colin, Cheng and Huizingh 2014; Gassmann et al. 2010; Marilungo et al. 2016; Wang and Zhou 2012; West and Bogers 2017). The complexity of innovation process increases because innovation relies on non-formal activities such as company interaction, shared experiences and technology adoption (Trott and Simms 2017).

The literature review indicates that there are differences in the characteristics of companies in developed countries with respect to companies in developing countries and that these differences affect the practice and results of open innovation. The model proposed by Alvarez and Bernal (2017) indicates that the success of open innovation in companies is due to the interaction of key factors such as human potential, organizational culture, strategy, organizational structure and the use of technologies of the information. OI is successful if it is motivated from within the organization and there is a high commitment of its managers (Colin et al. 2014; Marilungo et al. 2016; West and Bogers 2017); in these countries, a reflection of this motivation and commitment is the external accreditation and certification (Alvarez and Bernal 2017; Teran et al. 2011).

Lee, Park, Yoon and Park (2010) join this position and assures that there is a potential of OI based on networking among SMEs, especially, in those companies that are leveraged by public funds for OI activities (Teran et al. 2011; Dolfsma and Seo 2013). In Mexico, the National Registry of Science and Technology Institutions and Companies (RENIECYT, Spanish initials) by the National Science and Technology Council (CONACYT, Spanish initials) accredit organizations carrying out scientific and technological activities, in consequence, these can get public finance for OI activities.

Stanislawski and Lisowska (2015) show that OI is influenced by the resources of SMEs; however, their trend for cooperation with the environment increases. About external knowledge sourcing in SMEs, Brunswicker and Vanhaverbeke (2015) propose four strategies: supply-chain, full-scope sourcing, technology-oriented and application-oriented. Based on the previous proposition, it is indispensable to create a complex measure that shows features of OI in local footwear SMEs with handcraft processes in a traditional industry.

The type of research conducted in this study is explicative and cross-sectional. This study looks up to explain the technological and innovation capabilities of SMEs through OI in local footwear manufacturing companies in Guanajuato, Mexico. These SMEs constitute an important link in the productive chains and a dynamic source of economic growth in Latin American countries (ECLAC 2014). In Guanajuato, footwear manufacturing companies produce 53.8% of the total footwear production and concentrate the most activity in the sector in terms of job creation and contribution to GDP (INEGI 2015); therefore, it is relevant to understand their processes for innovation and the intensity of their OI activities.

The methodological design of this study is based on the epistemology of qualitative comparative analysis, inasmuch as this framework allows to design a quantitative and qualitative strategy with a set of research tools that are combined (Ragin 2014, Schneider and Wagemann 2012). The method used is qualitative response regression analysis. The LOGIT model allowed analysing the feasibility of the OI approach (dependent variable) based on the innovative and technological capabilities (independent variable) of footwear manufacturing SMEs according to indicators that have been designed during the last three years.

According to INEGI (2014), more than two thousand footwear companies are settled in Guanajuato of which 20.5% are SMEs; therefore, the targeted population in this research are 481 footwear companies because they concentrate the highest activity in the sector in Guanajuato -generation of jobs and contribution to the state GDP- and their pattern of growth that is significantly increasing. Additionally, recent studies show the leading role that medium-sized companies have in the new productive restructuring of emerging countries (ECLAC, 2014), such as Mexico.

The calculation of the sample size used was the formulae for finite populations; sample size of 33 SMEs was obtained at a 90 per cent confidence interval. The sample of factories installed in Guanajuato was selected randomly of National Statistical Directory of Economic Units (INEGI 2014), the class used was 31-33 manufacturing industries and the subclass 3162, corresponding to the footwear manufacturing.

The survey was applied to managers of the production area in the study units; in some cases, the managers held high-level positions because their immediate chief was the CEO of the company; in other cases, these managers held medium-level positions because their chief was an operating manager. The instrument was validated with Cronbach’s alpha test; a coefficient of 0.915 was obtained.

The models were calculated with Minitab 17®. Each of the indicators was statistically described and this description allowed the verification of the degree of univariate normality, through the calculation of the asymmetry and kurtosis coefficients. The LPM has several constraints on the results, consequently, the LOGIT model was calculated since it is necessary a probability model that increases as ![]() increases but that never goes outside the 0-1 interval and the relationship between and must be non-linear. In other words, “approaches zero at slower and slower rates as gets small and approaches one at slower and slower rates as gets very large” (Aldrich as cited in Gujarati and Porter 2010). Although in a LOGIT model the distribution of predictors is not critical, it was estimated because it was necessary to validate that no data caused distortion, nevertheless, no abnormal data able to distort the results was detected. In this case the LOGIT model is expressed by:

increases but that never goes outside the 0-1 interval and the relationship between and must be non-linear. In other words, “approaches zero at slower and slower rates as gets small and approaches one at slower and slower rates as gets very large” (Aldrich as cited in Gujarati and Porter 2010). Although in a LOGIT model the distribution of predictors is not critical, it was estimated because it was necessary to validate that no data caused distortion, nevertheless, no abnormal data able to distort the results was detected. In this case the LOGIT model is expressed by: ![]() .

.

The distribution of errors is presented below because for a LOGIT model, an extreme distribution is expected.

The qualitative response regression analysis was used since, as mentioned earlier, these are models in which the dependent variable is qualitative by nature (Gujarati and Porter 2010). This model allows to calculate the likelihood of applying OI in SMEs that manufacture footwear through of the LPM and the LOGIT model from their technological and innovation capabilities. The dependent variable “open innovation” (OI) is a dichotomous variable model that takes the value of one when it is determined that the company has the potential to apply an OI approach, and zero when the company does not demonstrate such potential.

In this model, by the characteristics of this Mexican industry and its socioeconomic environment that were mentioned previously, the first option is Y = 1 when the company has at least three out of five of the following characteristics: is accredited by RENIECYT; is linked with a research centre or university (LRC/U); has a quality certification (QS); their productive processes incorporate information technologies (IT); has initiated the automation of production processes (APP). The second option is Y = 0 when it does not accomplish at least three of the previous indicators. (Alvarez and Bernal 2017; Chesbrough 2011; Gassmann et al. 2010; Huizingh 2011; Marilungo et al. 2016; Teran et al. 2011; Wang and Zhou 2012).

These observable items are proxies that express several dimensions of OI. Accreditation by RENIECYT enables firms to receive funds for the implementation of research, development and innovation activities with its internal capabilities or in collaborative agreements; having linkages with academic parties supposes a mutual exchange of knowledge and exposure to new information (Huizingh 2011; Wang and Zhou 2011); awarding quality certification reflects openness to diverse outside sources (Alvarez and Bernal 2017; Teran et al. 2011); using IT to support internal innovation processes and to make them have better productivity and automation in their processes show interaction and absorption of external knowledge and effort to acquire technology and purchase embodied knowledge (Adamides and Karacapilidis 2018; Marilungo et al. 2016; West and Bogers 2017).

It is supposed that companies performing more than two activities are getting a higher level of innovation in a more complex and systematic way that involves a set of practices related to search and screening, collaborative processes and purchase of knowledge as core dimensions of OI (Ebersberger, Bloch, Herstad and Van 2012). The arithmetic mean of LRC/U, QS, IT, and APP is calculated too. The measurement of this variable in dichotomous way (OI.qualitative) and in a continuous range (OI.mean) allows to generate a robust model and to contrast the four models generated to study a causal relationship between OI and the innovative and technological capabilities of SMEs.

The four models are:

- LPM with OI.qualitative;

- LPM with OI.mean;

- Binary logistic regression with OI.qualitative;

- Ordinal logistic regression with OI.ordinal.

The independent variable “innovative and technological capabilities of SMEs” (ITC) is an index built using a geometric mean of indicators that were analysed as a proportion yet collected with an ordinal scale. The indicators that built the index are: industrial property records registered (IPRR); R&D projects that generated new products or processes (P-R&D); projects conducted in collaboration with public or private research centres (P-LRC/U); failed projects (P-F); failed projects in collaboration (P-FLRC/U); projects cancelled after investing 50% or more of the value of the project in collaboration (P-C50); overseas projects involving technology transfer (P-ITT); cost-benefit ratio of completed R&D projects (P-CBR) (Chesbrough 2007; Chesbrough and Crowther 2006; Gassmann et al. 2010; Kirschbaum 2005; Schroll and Mild 2011). The temporality of these indicators was retrospective over three years.

It was used an integrated independent variable through a geometric mean, in this case, the same index reflects on the learning or experience in projects that fail against those which succeed; in this moment, there is a global interest about OI to use an integrated variable (Chesbrough 2017; Ragin 2014; Schneider and Wagemann 2012). According to the methodology, the collection of indicators was measured along an ordinal scale, then the proportion of these was calculated, and finally this proportion was incorporated into the index.

As mentioned in section three, 33 companies were studied. The features of this sample are shown in Table 1. In respect of the quality of their processes, the certification issued to the footwear companies is the Mexican Shoes Quality (MSQ). This certification deals with human capital, product and process development, product planning, production scheduling and control, layout, engineering, cost management, commercial management, supply chain integration and collaboration with knowledge suppliers.

Table 1

Features of the sample

Feature |

Ratio (%) |

Companies registered in the RENIECYT |

48.5 |

Companies certified in MSQ |

21.2 |

Companies linked with a research centre or university |

23.8 |

Companies that have made any kind of innovation |

51.8 |

Companies that have introduced a new product to market. |

18.5 |

Companies that have innovated in design of product. |

100 |

Companies that have access to new markets. |

18.5 |

Companies that incorporate IT in the operation of their processes. |

87.9 |

Companies that use Enterprise Resource Planning platforms. |

18.2 |

Source: Data collected by the authors.

With respect to the incorporation of information technology (IT) in the operation of processes, according to fieldwork, companies use their own developments, with which they control the production process; also, they use commercial administrative systems for the operation of finance and distribution. Usually they consolidate their information manually using spread sheets.

The companies studied have an Internet connection, for compliance with their fiscal obligations and for communicating with suppliers, distributors, customers, workers, and points of sales. The SMEs are using information technology to create an online community to share knowledge, example given, one of the companies surveyed said that it belongs to a virtual network of six organizations, the network allows them to share knowledge about their best practices (new work platforms such as lean-six sigma; new sustainable materials such as water-based adhesives; practices of innovation such as business intelligence software). It is important to note that these companies are not in competition, because they manufacture distinct types of footwear.

The footwear manufacturing process involves the implementation of labour. However, 100% of the companies studied have begun a process of automating their traditional artisanal processes and have increased their technological level in the various stages of the process. The manufacturing process begins in the cutting department; the companies studied have integrated new laser cutting technologies (this technology consists of two lasers mounted on a conveyor belt system, driven by small gears and a servomotor to position the laser as instructed by a computer program). This technology is linked to production order information. The operators of the production lines have integrated this technology into their production system with basic training in information technology and supplementary computer courses.

In the stitching department, new technologies have been incorporated such as: Computer-Aided Design (CAD) for the creation of stitching programs and patterns on an AutoCAD platform; milling machines, which receive the CAD files, in order to process the stitching patterns and synchronize them with the sewing files; automated stitching machines (these operate with artificial intelligence algorithms, for processing scanned images of footwear components with video cameras), which determine the necessary corrections in real time during the application of the stitching depending on the displacement and deformation of the material. Stitching is the operation that requires the highest level of specialization in traditional footwear manufacturing processes, but with the incorporation of these technologies this specialization is not essential.

By means of a conveyor belt, in the assembly department, operations are synchronized, and production is duplicated at least twice as many pairs as in a traditional line (this technology uses a “step-by-step” forward movement system, a high-vacuum drying, and infrared reactivation system using integrated heat treatment tunnels). The companies studied report that they have achieved space savings through the unification of assembly lines, savings in shoe lasts through the rapid rotation of holders, energy savings, among other savings.

In the injection of the sole, there have also been process innovations, since they use robot arms that allow companies to produce higher quality products. Automation of the process was also identified in the components department, through the incorporation of new technologies with computer vision systems for the automated production of insoles using CAD systems.

The empirical evidence also reflects several success cases in the sample companies in other categories of the innovation. In the category of innovation in the manufacturing process, footwear SMEs in Guanajuato have been able to increase their level of technology and the flexibility in the manufacturing processes, now, they can create any production line with the same infrastructure.

The stitching department, itself, constitutes a competitive advantage for the company. In this department, the upper part of the shoe is made, meaning that it is the most important department in the process; many workers with a high degree of specialization are involved because most of the operations require manual production processes. Therefore, the competitive advantage is the level of labour flexibility, given the degree of specialization in a manual process; this allows the company to make 360°changes in production lines, thereby increasing its productivity. Table 2 shows some these projects developed with scientists and technicians to demonstrate the firsts traces of OI.

Table 2

Industrial research projects between companies, scientists and technicians

Project R&D |

Type of innovation |

Knowledge area |

Automation of production lines |

Process innovation |

Mechatronics; Industrial engineering |

Technological development of textures |

Product innovation (inputs) |

Sustainable chemicals |

Tannery waste in manufacturing of insoles |

Product innovation (sub product) |

Sustainable chemicals |

Technological development of footwear for diabetic feet |

Product innovation (final product) |

Biomechanics |

Technological development of footwear for flat feet |

Product innovation (final product) |

Biomechanics |

Technological development of biomechanics footwear for people using a ferule or splint |

Product innovation (final product) |

Biomechanics |

Source: Data collected by the authors.

Table 3 shows the significant correlations between OI and ITC. According to the methodology, a geometric mean was calculated to measure the innovation and technology capabilities of SMEs (ITC.geo.mean); based on this measurement, the Pearson correlation of OI. mean variable and ITC.geo.mean were calculated, the result was 0.846 (p-value = 0.000). There is a significant relation between both variables, therefore, the OI activities and technological and innovation capabilities of SMEs on traditional footwear manufacturing industry are closely related.

Table 3

Significant correlations

|

ITC.geo.mean |

P-C50 |

P-CBR |

OI.mean |

0.846 0.000 |

- 0.618 0.000 |

0.688 0.000 |

|

P-LRC/U |

P-ITT |

|

P-R&D |

0.568 0.001 |

0.531 0.002 |

|

Cell Contents: Pearson correlation P-Value (This value shows the level of significance within a statistical hypothesis test, this is representing the probability of the occurrence of a given event). |

|||

Source: Data collected by the authors.

The relationship between OI and P-C50 (projects cancelled after investing 50 % or more of the value of the project in collaboration) is significant with a downtrend; this means that if OI activities increase, then the cancelled projects decrease. The correlation between OI and P-CBR (cost-benefit ratio of completed R&D projects) is significant with an upwards trend; this means that there is a positive relation between OI activities and the profit ratio. In financial terms, these relationships are very important because they allow the company to optimize the use of resources and show that OI activities could be an investment and not an expense.

It should be noted that the R&D projects that generate new products or processes (P-R&D) have been significant with the number of projects conducted in collaboration with public or private research centres (P-LRC/U) and with projects that involve technology transfer (P-ITT). This means that there is significant learning involved in innovation management (complexity, complementarities, and commercialization).

The results showed that OI is intensified from the mobilization of the absorption capacity towards greater diversity of external flows. Additionally, in SMEs there is a growing trend towards the technological automation of the production process; they believe that the development of technological capabilities is essential for innovation. In this regard, footwear manufacturing companies are incorporating new forms of work organization, in which, through hybridizations with technology companies are modifying production methods.

Additionally, it is inferred that, the increase of the technological level of the production process has initiated the fragmentation of the specialization of labour, giving way to more flexibility, which intensifies the modification of their forms of work organization. The importation of the technology continues to play a key role in the technological and innovation capabilities of footwear manufacturing companies; however, the companies’ efforts to increase collaboration with local universities and research centres are increasingly notable because there is great scientific and technological potential in Guanajuato.

In the companies included in the sample, the incorporation of new technologies has not caused a reduction in shop floor personnel; these personnel have been incorporated in other production lines. Thus, it is inferred that the medium-sized footwear companies are playing an increasingly key role in the practice of innovation in the Guanajuato footwear cluster. Through subcontracting relationships, the medium-sized companies require compliance with certain standards of quality, accuracy, and variety of designs from the small companies; the former provide technological assistance so that the latter can develop the production capabilities necessary to comply with the requirements imposed thereupon. Technological assistance focuses on the redistribution of the production lines and the management of materials; the medium-sized companies advise on and encourage the practice of innovation.

It can be affirmed that SMEs in a cluster of traditional manufacturing industry (such as footwear) in an emerging country (such as Mexico), with weak competences can engage the OI activities to accelerate their technological and innovative capabilities. This paper proposes a framework of analysis that can improve our understanding of OI in a traditional cluster of a Latin America emerging economy.

It was found that there is a major in-house effort to reach the point of accumulating absorption capacity; it could be said that there is a double directionality of OI (to and from the company) at a certain level. As it was exposed in the models in this paper, the innovative and technological capabilities were strengthened with OI activities.

There is a high probability that SMEs operate OI model, despite the low technological level of their production processes. The results show OI in the different moments of their productive processes; these sheds more knowledge on the context of Guanajuato, which has been investigated in only a limited number of previous studies. Also, it provides results that could be tested in other traditional industries.

Future researches could test with a larger sample with a different methodology framework. The hypothesis that is constructed from the results is that innovative activity in SMEs depends on the innovation of the value chain; this could explain why the Mexican footwear cluster is evolving in the direction of compaction. The medium-sized companies outsource small companies for to obtain a greater proportion in the total production; these companies have increased their presence in export markets and their participation in domestic market.

Adamides, E., and Karacapilidis, N. (2018). Information technology for supporting the development and maintenance of open innovation capabilities. Journal of Innovation & Knowledge, 90, pp. 1-10

Agénor, P. and Dinh, D. (2013). From Imitation to Innovation: Public Policy for Industrial Transformation. World Bank - Economic Premise, (115), pp. 1-8.

Akhavan, P., Adalati, M., Sharifi, S. and Hosnavi, R. (2010). The challenges of knowledge management portals application and implementation: an Iranian organizations case study. International Journal of Industrial Engineering Computations, vol.1(1), pp. 79-93.

Álvarez, E. and Bernal, C. (2017). Open Innovation Model: Focus on Human Potential. Información tecnológica, vol.28(1), pp. 65-76.

Alvarez, L. and Cruz, O. (2016). Technology Management in Footwear Manufacturing: Innovation or Technique of the Production Process? Gestión y gerencia, vol.10(3), pp.

Berglund, H., and Sandström, C. (2017). Business model innovation from open system perspective: structural challenge and managerial solutions. International Journal of product development, 18(3/4), pp. 274-285.

Brunswicker, S. and Vanhaverbeke, W. (2015). Open Innovation in Small and Medium-Sized Enterprises (SMEs): External Knowledge Sourcing Strategies and Internal Organizational Facilitators. Journal of Small Business Management, No.53, pp. 1241–1263.

Chesbrough, H. (2007). Why companies should have open business models. MIT Sloan Management Review, vol.48(2), pp. 22.28.

Chesbrough, H. (2011). Bringing open innovation to services. MIT Sloan Management Review, vol.52(2), pp. 85.

Chesbrough, H. (2017). The Future of Open Innovation. Research-Technology Management, vol.60(1), pp. 35-38.

Chesbrough, H. and Crowther, A. (2006). Open Innovation: Researching a New Paradigm, Oxford University Press, USA.

CICEG. (2017). Retrieved at: www.ciceg.org

Colin C., Cheng C. and Huizingh E. (2014). When Is Open Innovation Beneficial? The Role of Strategic Orientation. Journal of Product Innovation Management, vol.31(6), pp. 1235-1253.

Dolfsma, W. and Seo, D. (2013). Government policy and technological innovation-a suggested typology. Technovation, 33(6-7), 173-179.

Ebersberger, B., Bloch C., Herstad, S. and Van, E. (2012). Open innovation practices and their effect on innovation performance. International Journal of Innovation and Technology Management, vol.9(6), pp. 1-23.

ECLAC (2014). Una promesa y un suspirar: políticas de innovación para pymes en América Latina. Santiago de Chile: CEPAL. 152 pp.

Gassmann, O., Enkel, E. and Chesbrough, H. (2010). The future of open innovation. R&D Management, vol.40(3), pp. 213-221.

Gujarati, D. and Porter, D. (2010). Essentials of Econometrics, McGraw-Hill, New York.

Huizingh, E. (2011). Open innovation: State of the art and future perspectives. Technovation, vol.31(1), pp. 2-9.

INEGI. (2014). Economic census. Retrieved at: www.inegi.mx

INEGI. (2015). National Institute of Statistics and Geography. Retrieved at www.inegi.mx Among statistics 2009, 2011, 2012, 2014, 2015.

Kirschbaum, R. (2005). Open Innovation in Practice. Research-Technology Management, vol.48(4), pp. 24-28.

Kutvonen, A. (2011). Strategic application of outbound open innovation. European Journal of Innovation Management, vol.48(4), pp. 460-475.

Lee, S., Park G., Yoon B. and Park, J. (2010). Open innovation in SMEs—An intermediated network model. Research Policy, vol.39, pp. 290-300.

Lin, J. (2017). Industrial policies for avoiding the middle-income trap: a new structural economics perspective. Journal of Chinese Economic and Business Studies, 15(1), pp. 5-18.

Marilungo, E., Coscia, A., Quaglia, A., Peruzzini, M. and Germani, M. (2016). Open innovation for ideating and designing new products services system. Procedia, No.47, pp. 305-310.

Ragin, C. (2014). The Comparative Method: Moving Beyond Qualitative and Quantitative Strategies. Moving beyond qualitative and quantitative strategic, University of California Press, USA.

Schneider, C. and Wagemann C. (2012). Set-Theoretic Methods for the Social Sciences, a guide to qualitative comparative analysis, Cambridge University Press, Cambridge.

Schroll, A. and Mild, A. (2011). Open Innovation modes and the role of internal R and D, An empirical study on open innovation adoption in Europe. European Journal of Innovation Management, Vol.14(4), pp. 475-495.

Secretary of Economy (2018). Direction of Light industries in Mexico. Retrieved at: https://www.gob.mx/se/acciones-y-programas/industria-y-comercio.

Shim, S., Park, K. and Choi, S. (2018). Sustainable Production Scheduling in Open Innovation Perspective under the Fourth Industrial Revolution. Journal of Open Innovation: Technology, Market, and Complexity, 4(42), pp. 1-5.

Stanislawski, R. and Lisowska, R. (2015). The Relations between Innovation Openness (Open Innovation) and the Innovation Potential of SMEs. Procedia Economics and Finance, No.23, pp. 1521–1526.

Teran, A., Rodriguez, C. and Bucci, N. (2011). La innovación abierta como elemento de análisis en las pequeñas y medianas industrias, caso sector metalmecánico. RAI, Vol.8(2), pp. 05-28.

Trott, P. and Simms, C. (2017). An examination of product innovation in low- and medium-technology industries: Cases from the UK packaged food sector. Research Policy, Vol.46(3), pp. 605-623.

Unger, K., Flores, D. and Perez, L. (2014). Competitividad y Especialización en el Bajío Mexicano: ¿Acaso una región homogénea? CIDE, México.

Wang, Y. and Zhou, Z. (2012). Can open innovation approach be applied by latecomer firms in emerging countries? Journal of Knowledge-based Innovation in China, Vol.4(3), pp. 163-173.

West, J. and Bogers, M. (2017). Open innovation: current status and research opportunities. Innovation, Vol.19(1), pp. 43-50.

Witt, U. (2017). Capitalism as a complex adaptive system and its growth. Journal of Open Innovation: Technology, Market, and Complexity, 3(12), pp. 1-15.

Wolff, D. (2010). Économie de l'innovation: le Rôle des Normes Techniques et des Brevets. Vie & sciences de l'entreprise, Vol.1(183-184), pp. 56-70.

Yuandi, W. (2012). Can open innovation approach be applied by late comer firms in emerging countries? Journal of Knowledge-based Innovation in China, Vol.4(3), pp. 163-173.

1. Titular (A) researcher and professor at the University of Guanajuato, campus Leon; leader of Track 5 in Academy of Management Sciences (Development and Sustainable). lc.alvarez@ugto.mx

2. Full time professor at the University of Nuevo León; Member of the National System of Researchers (CONACYT). alfonso.lopezlr@uanl.edu.mx

3. Professor at the Universidad Autónoma de Nuevo León. Ing.jesus.estrada@hotmail.com