Vol. 40 (Number 20) Year 2019. Page 26

SHAMIN, Roman V. 1; URYNGALIYEVA, Aizhan A. 2; SHERMADINI, Marina V. 3 & FILIPPOV, Pavel G. 4

Received: 27/03/2019 • Approved: 31/05/2019 • Published 17/06/2019

2. Formalization of the production process

4. Optimization of processes based on genetic algorithms

5. Model of optimization of production processes

6. Estimation of economic efficiency of evolutionary methods of optimization of production processes

ABSTRACT: This article deals with the optimization of production processes at advanced technological enterprises. An original approach based on evolutionary optimization algorithms, as well as the ideas of genetic algorithms, is proposed. The issues of economic expediency of evolutionary optimization are considered. An important advantage of these methods is that the optimization uses not a priori estimates but real achievements of production processes. The proposed approach allows not only finding optimal solutions for a given production process, but also developing new knowledge about the efficiency of production processes that can be fundamentally important for further science-intensive projects. |

RESUMEN: Este artículo trata sobre la optimización de los procesos de producción en empresas tecnológicas avanzadas. Se propone un enfoque original basado en algoritmos de optimización evolutiva, así como las ideas de algoritmos genéticos. Se consideran los temas de conveniencia económica de optimización evolutiva. Una ventaja importante de estos métodos es que la optimización no utiliza estimaciones a priori sino logros reales de los procesos de producción. El enfoque propuesto permite no solo encontrar soluciones óptimas para un proceso de producción dado, sino también desarrollar nuevos conocimientos sobre la eficiencia de los procesos de producción que pueden ser fundamentalmente importantes para futuros proyectos de ciencia intensiva. |

Advanced technological production should constantly optimize its own manufacturing processes, as the level of competition in the markets of high-tech products is increasingly high. To optimize production processes, one can use different methods depending on the purpose of optimization.

In this article, we consider the situation when it is necessary to achieve the best results in terms of quality in the implementation of production processes. In this case, it is possible that the costs of implementing the production process would increase to meet the quality of the product. This is because in the field of science-intensive production, product quality is the basis for ensuring the competitiveness of this product in the market.

In this article, evolutionary optimization is considered the main method for optimizing a production process. The idea of the method of evolutionary optimization is similar to the ideas of genetic optimization algorithms (Ashlock, 2006; Bäck, 1997).

The paper presents mathematical models and describes an algorithm for carrying out evolutionary optimization of production processes. The issues of economic expediency of evolutionary optimization in conditions of high-tech production are considered as well.

The production process is a sequence of production operations, which are provided by the actions of employees using tools. For the case of a knowledge-based industry, the representation of a given production process can be performed, as a rule, in various ways (Shamin et al., 2013a).

We denote by P a plan for the production process. In this case, through

we denote the set of production plans considered. We introduce a discrete time scale

for the production process considered. In this case, we assume that at the instant t0 the process begins, and at the time tK this process terminates.

Thus, we denote by Pm (tk) the state of the production process Pm at time tk.

Since then, as a rule, complex production processes consist of production operations that are performed not only sequentially, but also in parallel. We will assume that the instants of time tk are chosen so that at these times, all technological operations were either completed or not started. Thus, these time readings could be considered as reporting periods for the implementation of the production process (Shamin et al., 2017a)

Accordingly, in each reporting period, the value of the function that describes the quality of execution of previous steps should become known. This function depends on the selected implementation plan for the production process. We denote this function as follows:

We assume that the greater the value of the function F, the better the chosen implementation plan for the production process.

We note that the problem of constructing the optimal production process plan in the case under consideration differs significantly from classical optimization problems, since a priori it is not always possible to evaluate and choose the optimal plan for implementing the production process.

The idea of evolutionary optimization consists in the fact that the changes in the plan for the implementation of production processes occur during the implementation of this plan. At the same time, only relatively small changes are possible at each step. An important feature of evolutionary optimization is that this optimization occurs based on the objective results of the implementation plan for the production process.

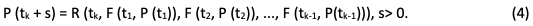

Formally, the procedure of evolutionary optimization is recorded by the following formula:

Here, R is a decision function that modifies production process plans. The meaning of this formula is that the plans of production processes are modified based on the results of previous reporting stages. The value of s is the meaning of the depth of the forecast. Usually, this value is 1.

The construction of decision functions in practice can be quite complex, since the options for changing the plans for the implementation of production processes are closely related to the specifics of production processes. Decision functions must satisfy the requirements of reliability under given conditions.

On the other hand, in high-tech production, there is great flexibility in the implementation of production processes and operations.

The described formalism of evolutionary optimization can be extended to the case when we consider simultaneously several identical production processes that pursue the same goal. In this case, optimization can be carried out using ideas based on genetic algorithms.

Genetic algorithms are algorithms for collective optimization of multidimensional functions. A feature of genetic algorithms is the partition of the desired solution. In this case, approximations to the solution are called genes, and the constituent parts are called chromosomes.

The idea of genetic algorithms is that one simultaneously optimizes not one gene, but an entire population of genes.

The optimization process uses the following basic procedures:

- random generation of new genes;

- gene crossing;

- gene mutation.

The operation of crossing genes is the most important in genetic algorithms. By crossing, we mean the operation of creating a new gene, which has a part of the chromosomes from one gene and part from another. At the same time, those genes that are better in relation to the optimized function are more likely to cross.

By mutation, we mean an operation in which a gene randomly changes one or more chromosomes.

Since the production process is divided into production operations, the genome can be understood as the actual production process and the chromosomes – as production operations.

The process of gene mutation corresponds to the process of evolutionary optimization of production processes, which is described in the previous section. Let us consider a formal model of the procedure for crossing production processes.

The plan for the realization of the production process is described not only by the totality of production operations and the sequence of their implementation, but also by a certain ideology of the organization of the production process. In the case of knowledge-intensive enterprises, as a rule, various ideological variants of the organization of production processes are possible. Therefore, the procedure of crossing production processes is possible not only at the level of crossing individual production operations, but also at the level of combining the ideologies of production process implementation plans.

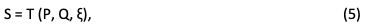

Let us consider two variants of production processes: P and Q. The results of crossing these production processes are a new production process S, which is formally determined by the following formula:

where ξ is some additional factors that arise when combining production processes. These factors cause some new production operations that are necessary to "glue together" the production processes, since the new production process must solve the same problem as the processes P and Q.

Consider now a model for optimizing production processes based on the evolutionary approach. Suppose that it is necessary to implement some production process in high-tech production.

To solve this problem, we form several parallel plans for the realization of a given production process (Shamin et al., 2015). We denote these plans as follows:

At the same time, we run parallel the initial stages of these processes.

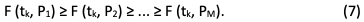

After the implementation of each reporting period, we evaluate the effectiveness of each version of the production process using the function F (tk, Pm). At each time count, for example, tk, we will renumber the versions of production processes in such a way that the following inequalities are satisfied:

We replace production processes with the mutation procedure and the crossover procedure. One of the options considers the scheme "best – worst." In this scheme, the production process P1, as the best, we leave unchanged, and the PM process, as the worst, we undergo a mutation procedure.

Changes in the worst production process can be quite drastic depending on the situation.

On the other hand, since at every step we leave the best process unchanged, we end up with a monotony for the best estimates of the production process.

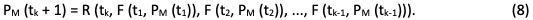

For production process plans P2, P3, ..., PM-1, we will use the crossing procedure. Officially, this is stated as follows:

where m = 2, 3, ..., M-1, and the indices m1 and m2 are chosen from the condition

The choice of these indices, as a rule, is carried out randomly, and the probability of choices for the index should be proportional to the quality of the production process plan with the given index. Thus, the best plans for the implementation of production processes are used more often in the crossing operation. This is one of the main mechanisms of optimization using methods of genetic algorithms.

The proposed scheme for optimizing production processes involves the simultaneous launch of several parallel production processes. In this situation, one needs to be sure that using this technique is financially justified. In this section, we consider these conditions. We also note that in science-intensive industries, one can sacrifice certain financial resources to ensure a higher quality of science-intensive product.

We introduce the function of average expenses for the realization of the production process P for the reporting periods:

For knowledge-intensive industries, this function usually has small values in the initial accounting periods, because at the beginning of the implementation of the projects, the theoretical work related to design takes place, and it does not require serious resource support. Therefore, an the beginning, the procedure of evolutionary optimization will most likely be financially justified.

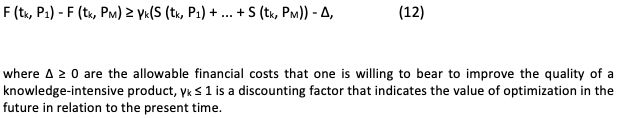

We assume that the function F estimated for the production process is calculated in monetary units. In this case, the condition of financial expediency of carrying out evolutionary optimization is considered as the following condition:

The meaning of this formula consists in the fact that the difference between the best and worst production processes must be greater than the total cost of parallel execution of production processes, taking into account the discount factor and the allowable costs.

In the event of this condition is violated, it is advisable to stop further optimization and to choose the plan P1 as the main plan of the production process implementation.

We note that when implementing such a procedure one not only finds the optimal solution for the production process plan, but also gains valuable experience in various approaches to project implementation, which in the conditions of science-intensive productions is of fundamental importance for future projects (Shamin et al., 2017b; Shamin et al.,2013b).

The practical use of models aimed to optimize production processes is related to making managerial decisions. In the case of evolutionary optimization, such decisions are made not as a result of modeling, but in its process. Consequently, effective mechanisms are needed to make these decisions.

Expert systems are the most effective method of decision-making. The idea of expert systems consists in the fact that the operator responds to system questions online and at the end, receives the system's conclusion about the optimal solution based on the information reported to the expert system.

The most important advantage of using expert systems is their objectivity in making decisions, since all these decisions are made based on pre-formalized withdrawal rules.

The principle possibility of the expert system in the dialogue mode allows using these systems in the process of evolutionary optimization when there is still no final information given. In this case, it is necessary to use special mechanisms of expert systems, which allow one to formulate intermediate conclusions based on available information.

This article suggests a new approach to optimizing the production processes of knowledge-intensive industries. This approach is based on the ideas of evolutionary optimization and genetic algorithms. An important advantage of these methods consists is that the optimization uses not a priori estimates but real achievements of production processes.

The proposed approach allows not only finding optimal solutions for a given production process, but also developing new knowledge about the efficiency of production processes that can be fundamentally important for further science-intensive projects.

The results of this article can be used to create various industry methods for increasing the effectiveness of knowledge-intensive production processes.

This paper was financially supported by the Ministry of Education and Science of the Russian Federation on the project No.26.1146.2017/4.6 "Development of mathematical methods to forecast efficiency of using space services in the national economy".

Ashlock D. (2006). Evolutionary computation for modeling and optimization. New York, Springer-Verlag.

Bäck T., Fogel D., Michalewicz Z. (1997). Handbook of Evolutionary Computation. Oxford, Oxford Univ. Press.

Shamin R.V., Chursin A.A., Fedorova L.A. (2017a). The Mathematical Model of the Law on the Correlation of Unique Competencies with the Emergence of New Consumer Markets. European Research Studies Journal, 3(a), 39-56.

Shamin R.V., Chursin A.A., Filippov P.G., Milkovsky A.G., Danilyuk A.Yu. (2015). Conceptual approaches to creating an automated system for assessing the effectiveness of using budget resources in the RCP. Economics and Entrepreneurship, 2, 808-815

Shamin R.V., Gurevich P.L., Tikhomirov S.B. (2013a). Reaction-diffusion equations with spatially distributed hysteresis. SIAM J. Math. Anal, 45(3), 1328-1355

Shamin R.V., Kovkov D.V., Okatiev N.A. (2013b). Mechanisms for estimating the cost of creating products of the rocket and space industry (RCP). Handbook. Engineering Journal with the application, 4 (193), 60-64.

Shamin R.V., Kozyrev O.R., Logvinova K.V., Obydennova S.Yu., Giniyatullin A.R., Shmelev A.G. (2017b). Economic-mathematical model of nonsmooth optimization in the problems of assessing the competitiveness of high technology enterprises. Proceedings of the NSTU. R.E. Alekseeva, 4, 50-54

1. Peoples' Friendship University of Russia (RUDN University), Miklukho-Maklay Street, 6, Moscow, 117198, Russia. E-mail: roman_v_shamin@mail.ru

2. Peoples' Friendship University of Russia (RUDN University), Miklukho-Maklay Street, 6, Moscow, 117198, Russia

3. Peoples' Friendship University of Russia (RUDN University), Miklukho-Maklay Street, 6, Moscow, 117198, Russia

4. Peoples' Friendship University of Russia (RUDN University), Miklukho-Maklay Street, 6, Moscow, 117198, Russia