Vol. 40 (Number 34) Year 2019. Page 19

RYAPUKHIN, Anatoly V. 1; KABAKOV, Vitaly V. 2 & ZARIPOV, Rushan N. 3

Received: 19/06/2019 • Approved: 28/09/2019 • Published 07/10/2019

ABSTRACT: The purpose of the paper is to study the issues of management of multi-module, multi-agent system for creating high-tech products. With the help of the method of analysis, it is established that automation of production processes provoked the strengthening of the role of the matrix type of control as one of the most efficient thanks to the flexibility in stimulating the competition, optimizing costs. |

RESUMEN: El propósito del documento es estudiar los problemas de gestión de sistemas de múltiples módulos y múltiples agentes para crear productos de alta tecnología. Con la ayuda del método de análisis, se establece que la automatización de los procesos de producción provocó el fortalecimiento del papel del tipo de matriz de control como uno de los más eficientes gracias a la flexibilidad para estimular la competencia, optimizando los costos. |

The “cold war” between the USSR and the USA that took place in the second half of the 20th century actually initiated a revision of the scientific and technical policy of a number of large countries towards the intensification of scientific and technical activities and the accelerated introduction of developments in areas related to the defense industry. Although competition between countries in industry was observed before, it was the “cold war” that gave a significant impetus to the understanding that the speed of invention and implementation comes in first place on the issue of innovative developments (Bilynsky et al., 2017). As a consequence, this thesis has repeatedly confirmed its relevance.

Moreover, the development of information technologies in terms of automating individual technical functions and data transmission in the process of implementing new ideas creates more and more new demand for accelerating the processes of creating and introducing an innovative product, and the time period is no longer determined by decades, but by years or even months, "Production tends to be more adaptive to evolutionary and revolutionary development leaps, to create innovative products faster than technology becomes obsolete and loses relevance and, to observe rational rates of renewal of fixed production assets” (Krivyakin, 2012).

In connection with the above-mentioned facts, the solution of problems associated with the maximum concentration of scientific and technical thought, its accelerated processing into a design conceptual apparatus and further implementation in the form of finished products is of particular relevance (Formalev et al., 2018a; Kakhramanov et al., 2017; Formalev and Kolesnik, 2016; Formalev and Kolesnik, 2017a; Formalev et al., 2018b; Bulychev et al., 2018a; Rabinskiy and Kuznetsova, 2018; Formalev and Kuznetsova, 2018; Lurie et al., 2015; Formalev and Kolesnik, 2017b; Rabinskiy and Tushavina, 2018; Lurie et al., 2017a; Babaytsev et al., 2017; Formalev et al., 2018c; Prokofiev et al., 2016; Formalev et al., 2017a; Formalev et al., 2017b; Formalev et al., 2016a; Formalev et al., 2016b; Lurie et al., 2017b; Okonechnikov et al., 2016; Krasovskii et al., 2018; Lomakin et al., 2017; Gidaspov et al., 2017; Bulychev et al., 2018b).

In the knowledge-intensive industry, there is virtually no time left for repeated revisions, fittings and product modifications, which take a considerable amount of time and increase the risk that the initiative will be taken by competitors. It is for this reason that in the sector of creation and introduction of innovations, the initiative is intercepted by small organizations that are able to flexibly approach the solution of the tasks and respond promptly to changing conditions. This approach is effective in case of small projects, but it is difficult to implement large-scale objectives, covering dozens and hundreds of large organizations.

For this reason, the heavy engineering industry is currently mostly oriented towards the divisional (including linear or linear-functional) management structure, which, despite its sluggishness, has clear, thoroughly studied mechanisms that allow planning activities for a relatively long period of time and assess risks with an acceptable level of confidence interval (Kryvonos et al., 2017). At the same time, “an analysis of positions of modern scholars in the study of organizational management structures shows that divisional management structures and matrix structures are inherent to large integrated structures for introducing innovations and adjusting to market changes” (Gadzhimetov and Schukin, 2017). Therefore, despite the fact that management understands the need for the development of innovations, the divisional type remains the basis for management, and the matrix approach is a kind of structure above (Plaskova et al., 2017).

Nonetheless, the problem is in the fact that there are competitors to the usual way of operating machine-building “monsters”, which are innovative companies of a new type, focused on getting commercialized results as soon as possible. And in order to compete effectively with them, it is necessary to change the structure of old companies.

In recent years, matrix type of management is accepted by more and more enterprises around the world. A significant number of fundamental and applied articles are devoted to this type of management. Despite its innovativeness and apparent attractiveness for the purpose of accelerating innovation processes in industrial enterprises, there are a number of features or limitations that do not allow this approach to be applied in large capital and material intensive industries. The main feature is the absence of effective mechanisms for managing systems consisting of multidimensional multi-element matrices, as a result of which attempts to create such systems inevitably lead to a linear-functional model, since in this case it is necessary to use a non-linear matrix concept that “is not based on the idea of building a management process originally defined by lines of the matrix, and on the idea of universal application of business processes that make it possible to implement many projects with product innovations. In this case, the management process is performed in two areas: functional innovations and unified processes”.

However, it is necessary to take into account that, in addition to the general saving effect, matrix systems have the advantage of a synergistic effect caused by brainstorming about independent elements temporarily united to solve specific tasks. Indeed, classical established structures with a mechanism of moderate renewal of personnel are much less effective in terms of generating new ideas and their implementation, since they are interested in maintaining existing economic and social ties, are reluctant to change them, and often are also reluctant to create new ones. For this reason, the mechanism of personnel rotation is used around the world, which cannot be used with a sufficient degree of efficiency in knowledge-intensive organizations, where the individual forms the environment, and not vice versa.

On this background, the widespread introduction of matrix-type management in science-intensive organizations is only a matter of time when it will be possible to formulate risk management and control mechanisms, which include “difficulties in ensuring a balance of power between managers of vertical and horizontal levels, disruption of communications between permanent and temporary participants work, the complexity of reporting and monitoring the work and interaction of a large number of projects in the company, the threat of dual subordination for employees and very high demands for their skills and competence ". At the same time, the problem of risks is crucial due to the fact that their control in such systems can only be performed in semi-automatic or automatic mode, since otherwise the management has to hire a large staff of controllers with appropriate qualifications, which will significantly worsen the expected economic effect and also reduce the indicator time effectiveness of product development and implementation.

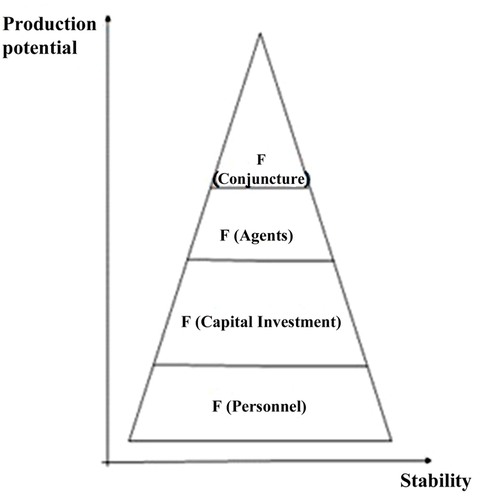

Developed with the participation of the authors of this article, the risk management approach “The concept of risk management for the knowledge-intensive organization 'Pyramid 4K'” allowed the company to “localize the most significant risks” of an organization, clearly demonstrating the stability of an economic entity to negative impacts by managing the system from the functions of four basic components (Figure 1), focused on the classical linear-functional management system of the organization, however, when performing certain transformations can be used in multi-modular structure (Zaripov et al., 2017).

It should be mentioned that the base and height of the pyramid are not constants and depend on both internal and external factors, and if the level of sustainability is determined mainly by the internal characteristics of the organization, the production potential is dictated by the market, i.e. consumer demands. And the effective management has to find a balance between costs of maintaining sustainability and the ability to offer modern competitive products by managing 4K functions.

Figure 1

"Pyramid 4K" factors of organization stability

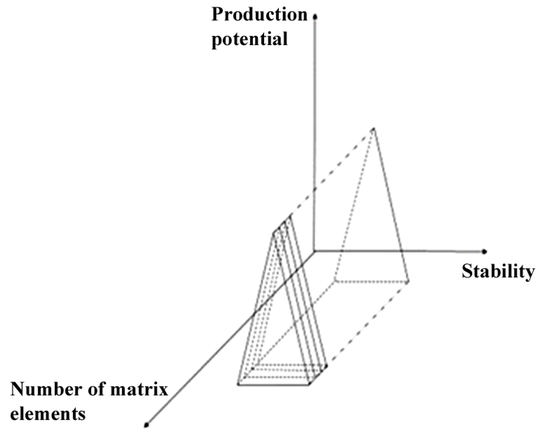

With regard of a multi-modular structure, this pyramid should be transformed into a prism (Figure 2), within which a third degree of freedom of the production system is added, due to the number of complex production units, which greatly complicates the process of managing the entire system, but allows to integrate into linear and functional mechanisms, giving us the assumption of a number of scientists about the presence of symbiosis between divisional and matrix control systems (Gadzhimetov and Schukin, 2017).On the other hand, in the context of a modern high-tech enterprise, the divisional component of such a system should be minimal and ideally tend to zero in order to make it more flexible.

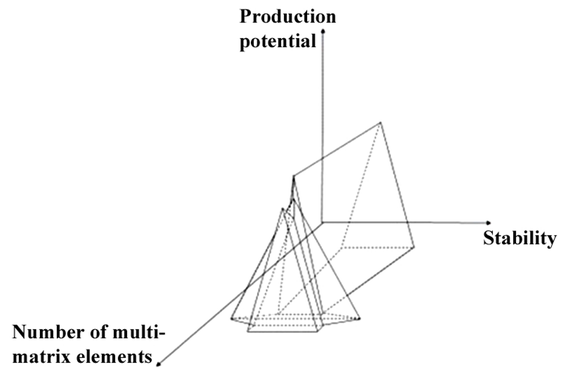

In addition, it should be mentioned that the presented construction is “ideal” when all the elements-modules are completely identical, which allows the use of standard management methods without significant pressure on the management. In practice, it is almost always possible to see instead of a prism a certain complex figure (Figure 3), whose stability and production potential are non-linear, as a result of which it is much more difficult to manage and it can be a subject to a greater number of uncertainties, with the result that each element should be governed by different principles and regulations from the ones used in divisional mechanism. Furthermore, in modern conditions for the management of such a system, it is expedient to develop and use automated intelligent systems as minimum necessary components of the overall management structure.

Figure 2

Prism of stability for multi-modular structure

-----

Figure 3

Realistic stability figure of multi-module structure

Therefore, the complexity of forming and making system decisions on the part of the control unit with respect to the multi-module structure is clearly demonstrated, since the generated 2* n degrees of freedom (where n is the number of elements of the system), are currently demand to create a large administrative apparatus.

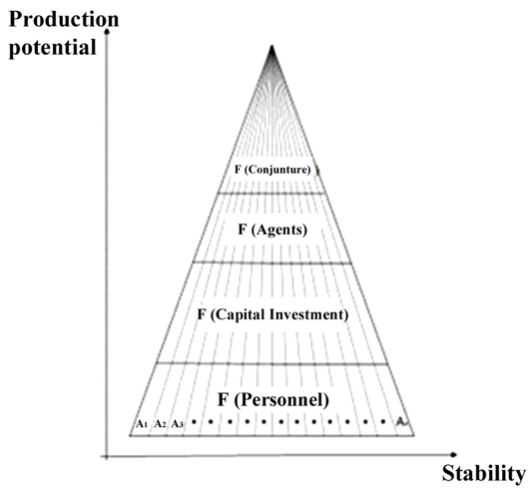

Nonetheless, the system will become even more complicated if a significant number of “agents” are present in the module of each production unit (Figure 4), i.e. conditionally independent entities carrying out initiative independent activities within the framework of a common production “web”.

It should be mentioned that each agent is a separate structural unit, which may include both an individual and a small group of individuals with a hierarchical structure of subordination, but essentially an intellectual unit, i.e. Head of a group with 2-3 assistants. Moreover, it should be noted that agents only nominally belong to one production unit, which can be a cluster, an enterprise, an institute, etc., i.e. site providing infrastructure for work. But in fact, agents can work on several projects, and the less their share of participation in a particular project, the smaller it the stability platform they form at the base of the “pyramid” of this module, which allows to evaluate their integral impact on the stability of the “prism”, and, as a result, monitor the level of risk posed by this agent.

Figure 4

The diagram of the production unit consisting of k-agents

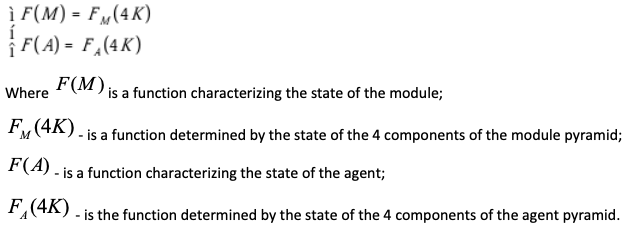

The presented graphic materials make it possible to visually assess the complexity of making a mechanism for the effective management of a multi-module system with a large number of agents in each module. At the same time, they make it possible to form a system of two dependency equations, the solution of which would allow finding the answer regarding the effective control mechanism of a complex multi-modular multi-agent system:

Taking into account the fact that there is a large number of degrees of freedom of such a multi-matrix, when solving the reduced system of equations, it can be assumed that complex multifactor dependencies are obtained which, under the existing conditions of insufficient automation of the intellectual process, will not allow the project management to make correct decisions promptly. In this regard, it is suggested to split the management process into two subsystems:

The first subsystem, directly related to the project management, should be concentrated on the formation of a common project framework along the maximum edges of the "prism", which will allow maintaining the stability and production potential at the required level. Within the framework of this subsystem, it is expedient to establish a list of indicators of modules and agents that can be traced both at the stage of attracting agents and in the process of project implementation.

The second subsystem is designed to accomplish internal control of production processes by agents themselves on the principle of block-chain technology on two main indicators: quality and the time of receipt of products from the previous agent. It should be mentioned that it is the block-chain technology that is able to control a large number of business processes that are going on in parallel and, if necessary, to identify problems in a timely manner, sending the appropriate signal to the management structure. Such an approach will make it possible to form an effective competitive mechanism for managing the risks of creating and introducing innovative products of heavy engineering.

However, it must be kept in mind that the proposed approach is analytical. In practice, we should take into account the kind of the enterprise, i.e. its main focus on the result: scientific activities, the introduction of new developments, the launch of a product on the market, etc. And one of the objectives of the subsequent work in this direction will be the formalization and mathematical description of the 4K functions.

Within the context of this work, the main modern types of industrial enterprise management were considered, and their advantages and disadvantages were described. The inexpediency of using the division type of management, as conservative and insufficiently flexible for the purpose of creating a high-tech product and promptly bringing it to the market, was proved. Moreover, shortcomings were identified in the application of the matrix type of management to large high-tech enterprises and ways to reduce them were identified. Based on the analysis, a method was developed for graphical monitoring and risk management of complex research and production systems operating on a matrix basis. Considering the complexity of management of such systems and the lack of perfection of management mechanisms, the matrix principle has not yet been widely used in large research and production enterprises and projects, partially because of the high risks of negative factors for an agent or matrix module that are insignificant to linear functional control mechanisms.

At the same time, currently the matrix mechanism is one of the most promising. And the designing risk management mechanisms for such systems is one of the priority objectives both at the industry level and at the government level, since it will radically improve the efficiency of functioning of high-tech industries and significantly improve their competitiveness and scientific and technical potential.

In subsequent works on this theme, it is planned to develop a set of theoretical mathematical models identified in this article, to accomplish statistical collection of information on real high-tech projects in order to conduct correlation studies, and to form a set of applied mathematical models that will allow quantifying the sustainability risks of multi-modular multi-agent systems, and as a result, perform strategic planning activities within some industries and the economy as a whole.

Babaytsev, A.V., Prokofiev, M.V., & Rabinskiy, L.N. (2017). Mechanical properties and microstructure of stainless steel manufactured by selective laser sintering. International Journal of Nanomechanics Science and Technology, 8(4), 359-366. DOI: 10.1615/NanoSciTechnolIntJ.v8.i4.60.

Bilynsky, Y.Y., Ratushny, P.M., Yukysh, S.V, Barylo, A.S., Amirgaliyev, Y., Kotyra, A., Burlibay, A., & Morarenko, V. (2017). Contouring of microcapillary images based on sharpening to one pixel of boundary curves. Proceedings of SPIE – The International Society for Optical Engineering, 10445, 104450Y.

Bulychev, N.A., Kazaryan, M.A., Kirichenko, M.N., Garibyan, B.A., Morozova, E.A., & Chernov, A.A. (2018a). Obtaining of hydrogen in acoustoplasma discharge in liquids. Proc. SPIE, 10614, 1061411.

Bulychev, N.A., Kuznetsova, E.L., Bodryshev, V.V., & Rabinskiy, L.N. (2018b). Nanotechnological aspects of temperature-dependent decomposition of polymer solutions. Nanoscience and Technology. An International Journal, 9(2), 91-97. DOI: 10.1615/NanoSciTechnolIntJ.2018025703.

Formalev, V.F., & Kolesnik, S.A. (2016). Analytical investigation of heat transfer in an anisotropic band with heat fluxes assigned at the boundaries. Journal of Engineering Physics and Thermophysics, 89(4), 975-984.

Formalev, V.F., & Kolesnik, S.A. (2017a). On inverse coefficient heat-conduction problems on reconstruction of nonlinear components of the thermal-conductivity tensor of anisotropic bodies. Journal of Engineering Physics and Thermophysics, 90(6), 1302-1309.

Formalev, V.F., & Kolesnik, S.A. (2017b). On inverse boundary heat-conduction problems for recovery of heat fluxes to anisotropic bodies with nonlinear heat-transfer characteristics. High Temperature, 55(4), 564-569.

Formalev, V.F., & Kuznetsova, E.L. (2018). Mathematical modeling of the Stefan's problems with the determination of the coordinates and the velocities of the dynamically moving borders of phase transformations. Periodico Tche Quimica, 15(Special Issue 1), 377-389.

Formalev, V.F., Kolesnik, S.A., & Kuznetsova, E.L. (2016a). Nonstationary heat transfer in anisotropic half-space under the conditions of heat exchange with the environment having a specified temperature. High Temperature, 54(6), 824-830.

Formalev, V.F., Kolesnik, S.A., & Kuznetsova, E.L. (2017a). Time-dependent heat transfer in a plate with anisotropy of general form under the action of pulsed heat sources. High Temperature, 55(5), 761-766.

Formalev, V.F., Kolesnik, S.A., & Kuznetsova, E.L. (2018a). Wave heat transfer in the orthotropic half-space under the action of a nonstationary point source of thermal energy. High Temperature, 56(5), 727-731.

Formalev, V.F., Kolesnik, S.A., & Kuznetsova, E.L. (2018b). Analytical study on heat transfer in anisotropic space with thermal conductivity tensor components depending on temperature. Periodico Tche Quimica, 15(Special Issue 1), 426-432.

Formalev, V.F., Kolesnik, S.A., & Kuznetsova, E.L. (2018c). On the wave heat transfer at times comparable with the relaxation time upon intensive convective-conductive heating. High Temperature, 56(3), 393-397.

Formalev, V.F., Kolesnik, S.A., Kuznetsova, E.L., & Rabinskii, L.N. (2016b). Heat and mass transfer in thermal protection composite materials upon high temperature loading. High Temperature, 54(3), 390-396.

Formalev, V.F., Kolesnik, S.A., Selin, I.A., & Kuznetsova, E.L. (2017b). Optimal way for choosing parameters of spacecraft’s screen-vacuum heat insulation. High Temperature, 55(1), 101-106.

Gadzhimetov, B.E., & Schukin, O.S. (2017). Transformation of structures of integrated enterprises of the military-industrial complex. Bulletin of the Voronezh State University. Series: Economics and Management, 4,83-88.

Gidaspov, V.Y., & Severina, N.S. (2017). Numerical simulation of the detonation of a propane-air mixture, taking irreversible chemical reactions into account. High Temperature, 55(5), 777-781.

Kakhramanov, R.M., Knyazeva, A.G., Rabinskiy, L.N., & Solyaev, Y.O. (2017). On the possibility of steady-state solutions application to describe a thermal state of parts fabricated by selective laser sintering. High Temperature, 55(5), 731-736.

Krasovskii, V.I., Feofanov, I.N., Rasmagin, S.I., Zadorin, D.A., Zakharyan, R.A., Kazaryan, M.A., Chaikov, L.L., Bulychev, N.A., Averyushkin, A.S., & Garibyan, B.A. (2018). Non-linear optical properties of nanosized metal oxide particles obtained in plasma discharge in liquid phase under ultrasonic cavitation. Proc. SPIE, 10614, 10614OZ.

Krivyakin, K.S. (2012). Features of the production of high technology products. Bulletin of the Voronezh State Technical University, 8(8), 74-76.

Kryvonos, Y.G., Romanov, V.O., Galelyuka, I.B., Wójcik, W., Zyska, T., & Amirgaliyev, E. (2017). Independent devices and wireless sensor networks for agriculture and ecological monitoring. Recent Advances in Information Technology, 1, 105-134

Lomakin, E.V., Lurie, S.A., Belov, P.A., & Rabinskii, L.N. (2017). Modeling of the localy-functional properties of the material damaged by fields of defects. Doklady Physics, 62(1), 46-49.

Lurie, S.A., Kuznetsova, E.L., Rabinskii, L.N., & Popova, E.I. (2015). Erratum to refined gradient theory of scale-dependent superthin rods. Mechanics of Solids, 50(2), 135-146.

Lurie, S.A., Rabinskiy, L.N., Polyakov, P.O., Sitnikov, S.A., & Solyaev, Y.O. (2017a). Mechanical properties of Si3 N4 -based composite ceramics with nanosized porosity. International Journal of Nanomechanics Science and Technology, 8(4), 347-358. DOI: 10.1615/NanoSciTechnolIntJ.v8.i4.50.

Lurie, S.A., Solyaev, Y.O., Lizunova, D.V., Rabinskiy, L.N., Bouznik, V.M., & Menshykov, O. (2017b). Influence of mean distance between fibers on the effective gas thermal conductivity in highly porous fibrous materials. International Journal of Heat and Mass Transfer, 109, 511-519.

Okonechnikov, A.S., Rabinskiy, L.N., Tarlakovskii, D.V., & Fedotenkov, G.V. (2016). A nonstationary dynamic problem on the effects of surface loads on a half-space with a nanosized structure within the framework of the cosserat medium model. International Journal of Nanomechanics Science and Technology, 7(1), 61-75. DOI: 10.1615/NanomechanicsSciTechnolIntJ.v7.i2.10.

Plaskova, N.S., Prodanova, N.A., Zatsarinnaya, Е.I., Korshunova, L.N., & Chumakova, N.V. (2017). Methodological support of organizations implementing innovative activities investment attractiveness estimation. Journal of Advanced Research in Law and Economics, 8(8), 2533-2539. DOI:10.14505/jarle.v8.8(30).25.

Prokofiev, M.V., Vishnevskii, G.E., Zhuravlev, S.Y., & Rabinskiy, L.N. (2016). Obtaining nanodispersed graphite preparation for coating ultrathin mineral fibers. International Journal of Nanomechanics Science and Technology, 7(2), 97-105. DOI: 10.1615/NanomechanicsSciTechnolIntJ.v7.i1.40.

Rabinskiy, L.N., & Kuznetsova, E.L. (2018). An alytical and numerical study of heat and mass transfer in composite materials on the basis of the solution of a Stefan-type problem. Periodico Tche Quimica, 15(Special Issue 1), 339-347.

Rabinskiy, L.N., & Tushavina, O.V. (2018). Experimental investigation and mathematical modelling of heat protection subjected to high-temperature loading. Periodico Tche Quimica, 15(Special Issue 1), 321-329.

Zaripov, R.N., Murakaev, I.M., & Ryapukhin, A.V. (2017). The concept of risk management of a modern industrial enterprise – “Pyramid 4K”. Economy and Entrepreneurship, 11(88), 827-830.

1. Department of Radio Systems and Control Systems, Information Transmission and Information Security. Moscow Aviation Institute (National Research University). Moscow. Russian Federation. E-mail: ryapukhin_av@mai.ru

2. Department of Technological Design and Quality Management. Moscow Aviation Institute (National Research University). Moscow. Russian Federation. E-mail: ser-kvv73@mail.ru

3. Department of Optimization of Management Mechanisms of the Rocket and Space Industry and Forecasting of Risks of Its Activity. FSUE “Organization "Agat". Moscow. Russian Federation. E-mail: rushan@yandex.ru