Vol. 40 (Issue 37) Year 2019. Page 27

TYURINA, Yuliya 1; TROYANSKAYA, Marija 2; KUZNETSOVA, Tatyana 3 & KREMLEVA, Lyudmila 4

Received: 19/07/2019 • Approved: 17/10/2019 • Published 28/10/2019

ABSTRACT: Economy robotization is a relevant issue for both developed and developing countries. Recently robotization has become available even in non-industrialized countries. The introduction of robotization into production processes increases the competitiveness of the economy. Thus, it is a great impetus for improving the living standard of the population. In our research, we have considered many aspects of the influence of robotization on the national economy and analyzed the robotization processes in developing countries, as well as the impact of robotization on the unemployment rate. |

RESUMEN: La robotización de la economía es un tema relevante tanto para los países desarrollados como para los países en desarrollo. Recientemente, la robotización ha llegado a estar disponible incluso en países no industrializados. La introducción de la robotización en los procesos de producción aumenta la competitividad de la economía. Por lo tanto, es un gran impulso para mejorar el nivel de vida de la población. En nuestra investigación, hemos considerado muchos aspectos de la influencia de la robotización en la economía nacional y analizado los procesos de robotización en los países en desarrollo, así como el impacto de la robotización en la tasa de desempleo. |

Robotization is the development of industrial automation with the use of industrial robots (Nehmzow, 2008)

Industrial robots are defined as “the devices that perform general and flexible movements similar to those of human limbs and/or which ensure flexible movement through their sensing and recognizing capabilities”. A robot must be regarded as a single element in a Flexible Manufacturing System (Tokhi & Azad, 2010).

Robots are a key tool for increasing productivity and the living standard. Nowadays, robotics is the most widely implemented in the industry. There has been developed a wide range of robots, capable of more efficiently and consistently performing various operations previously done by humans. The development of technology expands the use of robotics in many other sectors, from agriculture to logistics and hotel business. Robots are becoming increasingly important for economic productivity and competitiveness. The level of robotics implementation is a crucial economic indicator, as it reflects the development and progress of the country.

Many leading world economies have consolidated the provisions on the strategy of robotic innovation and the introduction of robots in their development strategies.

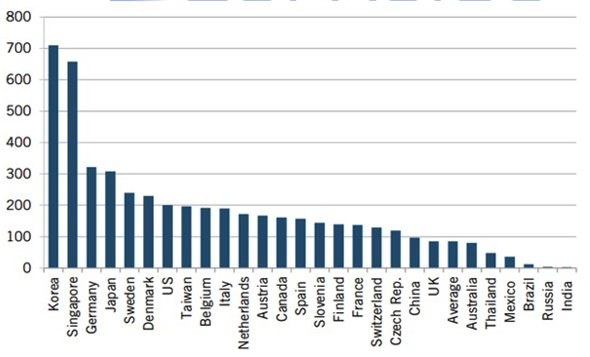

In general, Fig. 1 shows the situation related to the replacement of human labor by robots. (Kruglov et al., 2017)

Figure 1

Robots Per 10,000 Manufacturing Workers, 20177

According to Jeong et al. (2011) current robotization research is mainly focused on the modern and cutting-edge technology developments. As for the fact that robotization reduces the number of workplaces, it should be noted that these studies used a simple regression analyses regarding robotization as an independent variable and employment as a dependent variable. Robotization also increases along with the company’s growth. This means that robotization is more likely to be observed in bigger companies due to the fact that they can relatively easy get funds required for robotization compared to small- and medium- sized enterprises (Jeong et al., 2011; Chui et al., 2015).

Robotics is one of the core technologies of the 4th Industrial Revolution. It is an essential and integral automation element in most manufacturing industries. (Cho & Kim, 2018) These industries include the automotive industry and the growing semiconductor industry. In 2003-2010, the annual demand for industrial robots in manufacturing industries increased from 81,000 units to 121,000 units. At the same time, the world gradual documented growth rate was 6%. There was a robotics boom until 2015, with an annual growth rate of 16% (International Federation of Robotics.World Robotics, 2016). However, due to the rapidly growing demand for industrial robots, there is a rising concern that robot-based innovation in industrial technology could result in widespread job losses despite the fact that robotic innovation contributes to productivity. The 2016 World Economic Forum (World Economic Forum, 2016) also forecasts that the 4th Industrial Revolution will have a positive impact on the economy through improving productivity, while having a negative impact due to the increased unemployment rate worldwide. There is a possibility of job losses due to technological changes. (Frey & Osborne, 2017)

Based on theoretical considerations, in a growing economy with a labour shortage the introduction of robots leads to an increase in output and labor productivity rather than an increase in unemployment. This can be explained by the fact that robots replace ageing workers who leave their jobs or workers who move on to other tasks such as inspection or maintenance. According to Moriguchi (1998), robots do not actually replace workers in large numbers, but help small-sized enterprises suffering from shortages of young workers. The infrastructure needed for the introduction of robots is created by older retired workers. Robots have also saved some labor-intensive industries that have lost their competitive advantage due to high labor costs (Moriguehi, 1989).

Technological advances and robotization contribute to the creation of a wide range of industries which do not need people as a labor force. This radically changes the existing system of social and economic relations.

For example, robots are used the most effectively in the construction industry. It is not always enough to mechanize and automate construction operations through conventional methods to provide the desired outcomes. The introduction of robots promotes construction technologies. The analysis of the major types of construction work shows that mounting and finishing operations are of the greatest practical interest in the application of robots. The technological and economic analysis of these types of work outlines technological operations most suitable for robotization. Mounting operations include mounting of components and structures, as well as welding. In finishing operations, priority is given to the preparation of the surface and its priming and painting. As for maintenance, robotization of washing, painting and waterproofing of outer building walls is of interest. The analysis of the developments in the field of construction robotics indicates that the desired outcome can only be achieved through the use of special-purpose robots and by fully considering technological, design, and operational features of construction operations. (Bock et al., 2002)

Some major studies devoted to current millennium challenges are focused on recent technologies aimed at disrupting the existing market and offering new opportunities. Moreover, according to the feasibility study, robotics is a turning point in this case. However, the distribution of its impact discriminates those who should theoretically enjoy the latest advances and developments – the disabled. Most of them are often excluded from any participation in the public environment. The inclusion of these aspects into the strategic environment is a controversial aspect of the social progress model, which is a serious problem. A wider dissemination of research developments based on their significance and quality will stimulate more exchanges and collaboration in the research community and contribute to further advancement of this rapidly growing field (Micevičienė et al., 2015).

Robots also penetrate into the domestic sphere. The proliferation of machines in the domestic sphere is actually characterized by some important elements, which make the management of these technologies unstable for capital. On the one hand, these machines are a powerful tool to control material and immaterial labor, like in the factory. This command is applied to time, modes and intensity of housework and its continuous reorganization. In practice, these machines structure domestic chores, enhance the overlapping of multiple tasks, create leisure activities, orient imagination and immaterial labor by imposing their own vision of the world and constantly track the division and cooperation between family members. For example, they control the specific organization of daily routines by setting the sequence of tasks and activities to be performed during the day (for example, millions of people eat when watching TV news). They also shape family discipline and push its members to work together to achieve an adequate level of reproduction (Fortunati, 2017).

Robotization is also becoming popular in logistics. Industrial robots used to be immobile and non-intelligent machines performing simple repetitive tasks with a high level of accuracy. That’s enough for simple production processes but not for most logistics activities. In logistics, the requirements for industrial robots are much higher. In logistics, robots must be able to distinguish between a number of goods, as well as between various parts in an infinite number of combinations; they must be able to work with people, to perceive their environment, as well as move and interact there. Increased flexibility and lower cost of robotized workplaces create prerequisites for the use of robots in logistics activities such as order picking, packing and shipping, as well as delivery. In logistics 80% of labor force is people. The problem of unfavorable demographic situation and the declining number of employees associated with it can be solved by the introduction of robots in some logistics activities. (Mikušová et al., 2017 )

In order to bridge the gap, there should be proposed a system of economic analysis to assess the economic impact of robotics on the labor market, as well as on the disabled. There are some assumptions:

There are arguments supporting the fact that human nursing care will never be completely replaced by robots for cultural, religious and other reasons, but care workers face the aging problem as well. Furthermore, the workers replaced by robots will be integrated in the creation of a commercial or market value chain which will also contribute to the productivity growth in national economy (Geishecker & Görg, 2008)

David Wright, a Deloitte expert, concludes that most companies do not want their employees to leave. On the contrary, they offer most of them jobs that require greater qualifications: as soon as routine processes can be automated, common service centers will start to provide additional services, and specialists will be needed for this. Despite this, an error may occur in the work of robotic technology, and therefore a person is needed to monitor its functioning. In fact, senior executives of the company will have to train their employees before production automation and robotization take place (Watry, 2016)

Based on the above mentioned facts, we can define the objectives of our research:

- to analyze the impact of robotization on the national economy;

-to analyze robotization processes in developing countries;

- to analyze the impact of robotization on the unemployment rate.

The object of our research is the impact of robotization processes on the economies of developing countries.

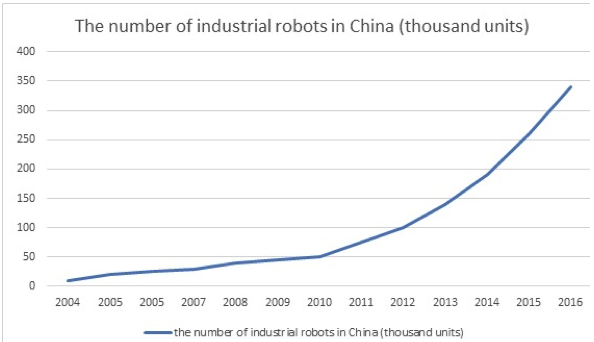

The number of industrial robots in Chinese enterprises from 2004 to 2016 was analyzed with the use of the statistical analysis method. We used the 2017 Statistical Bulletin on the Development of Ministry of Human Resources and Social Security, which is available at: http://www.mohrss.gov.cn/wap/fw/rc// 201805 / W020180521567611022649.pdf

We also used the extrapolation method in order to analyze the trends in the growth of the number of robots in China in different years, as well as South Korean legislation related to the development of robotization.

The prognostic research method helped to understand how robotization will affect the employment and the economies of developing countries.

Automation processes will be actively implemented only in developed countries - the USA, Canada, EU countries, as well as in some developing countries – for example, China and India.

The main task of developing countries is to increase the economic development level. At the same time, robotization will become a great impetus to this. The research that has been carried out in various countries has shown that in a modern industrial enterprise, supply and marketing costs (transportation, warehousing and auxiliary operations) may be as high as 70% of the total value of the finished product. As a rule, this is less than 10%. Thus, it can be seen that rational organization of these operations is one of the most important tools for restraining the growth of production cost.

In the context of fast-track renewal of the product assortment, it becomes very important to resolve the problems associated with increased operational restructuring of production for the output of new items, their quality improvement and the reduction of material costs. These problems are being solved successfully within the framework of modern flexible production systems that make it possible to involve with very few people, and in the future to use the technology that does not require any operating personnel, thus completely eliminating manual labor in transportation, warehousing and auxiliary operations. Automated transportation and warehousing systems belong to the various systems that ensure functioning of flexible production systems. Their role is determined by a number of factors, including the high costs for transportation, warehousing, and auxiliary operations compared to the production cost (Rodnkiov, 1991 ).

According to the International Federation of Robotics, China has become the largest importer of robots. The country is expected to hold this position in the future. Industrial robotization is one of the basic elements of production modernization performed in the framework of the “Made in China 2025” plan. (Made in China, 2018).

A typical example of the beginning of the overall robotization in China is the South Chinese enterprise Everwin Precision Technology: a year ago there were 650 people working there, and today there are only 30 operators of 10 automated conveyors. The number of the operational staff was reduced by 20 times. But this is only the first step. The company is located in the industrial cluster of Dongguan, Guangdong Province. It is going to increase the number of robots to 1,000 in order to automate production by 80% by 2017. This company is not the only example and there are a lot of other enterprises. As it has already been mentioned, China has become the largest importer of robots and is expected to hold this position in the future.

Dongguan will become a test platform for further robotization of the whole country. Since the 1980s, Dongguan, a city located between the regions of Guangzhou, Shenzhen and Hong Kong, has been an important production site for the light industry in the framework of the reform and opening-up policy in China. The crisis of 2008 seriously affected the producers of the region, and the focus on the domestic market development resulted in a regular labor shortage of up to 200,000 workers. Therefore, it was decided to implement a plan to automate production.

The whole country is affected by the labor shortage problem: according to the latest data, the working-age population (16-59 years old) declined by 4.87 million people in 2015 and reached 911 million. This trend will continue in the future (Kennedy, 2015).

Table 1 shows the number of the employed and the number of new jobs in China in 2011-2017.

Table 1

The number of the employed and the

number of new jobs in China in 2011-2017.

Year |

2011 |

2012 |

2013 |

2014 |

2015 |

2016 |

2017 |

Total employment, millions people |

764, 20 |

767, 04 |

769, 77 |

772, 53 |

774,51 |

776, 03 |

776, 40 |

Primary sector, million people |

265, 94 |

257, 73 |

241, 71 |

227, 09 |

219,19 |

214, 96 |

209, 63 |

The share of people working in the primary sector |

34, 8% |

33, 6% |

31, 4% |

29, 5% |

28,3% |

27,7% |

27% |

Secondary sector, million people |

225,44 |

232,41 |

231,7 |

230,99 |

226,93 |

223,5 |

218,17 |

The share of people working in the secondary sector |

29,5% |

30,3% |

30,1 % |

29,9% |

29,3% |

28,8% |

28,1% |

Tertiary sector, million people |

272, 82 |

276,9 |

296,36 |

313, 64 |

328,39 |

337, 57 |

348, 6 |

The share of people working in the tertiary sector |

35,7% |

36,1% |

38,5% |

40,6% |

42,4% |

43,5% |

44,9% |

Number of new jobs, millions |

12,21 |

12,66 |

13,1 |

13,22 |

13,12 |

13,14 |

13,51 |

China is dominating the robotics market, which is the most dynamic one in the world. Electronics and electrical engineering are key drivers the Chinese economy growth. (Kruglov et al., 2017)

Chinese robot manufacturers are expanding their market share. The statistics is given in Fig.2.

Figure 2

Dynamics of the number of industrial robots in China for 2004-2016.

According to the statistics, South Korea has the largest number of robots per capita. In the production sector, there are 710 industrial robots per 10,000 South Korean workers, while the world average is 85 robots per worker.

In 2008, the Intelligent Robots Development and Distribution Promotion Act was adopted in South Korea. According to this document, the government’s objectives in the field of robotics are:

Automation and robotics are the most widespread in China and South Korea compared to other developing countries. This contributes to the development of their economies. All developing countries should follow the example of China and South Korea, developing plans and strategies for robotization and automation in order to improve the economy

Robotization is a contentious issue. Some scientists argue that robotization is dangerous and it will deprive the majority of people of their workplaces. Other scientists have an opposite opinion and believe that economy robotization will provide more job opportunities.

There are a lot of questionable arguments in the literature related to the current industrial transformation. Enthusiasts regard robotization as an advance that frees people from unsatisfactory work and poverty. The same phenomenon is viewed by skeptics as the ominous contributor to mass unemployment. They believe that the introduction of robotics is may lead to a greter divide between the haves and the have-nots. So far the actual and anticipated human, organizational and social impacts of robotization on the major industrial giants have been based mainly on the assumptions rather than empirical research (Hollon & Rogol, 1985).

As it has been already mentioned, robotics is one of the core technologies of the 4th Industrial Revolution. It is an essential and integral automation element in most manufacturing industries (Cho & Kim, 2018) These industries include the automotive industry and the growing semiconductor industry. In 2003-2010, the annual demand for industrial robots in manufacturing industries increased from 81,000 units to 121,000 units. At the same time, the world gradual documented growth rate was 6%. There was a robotics boom until 2015, with an annual growth rate of 16% (International Federation of Robotics.World Robotics, 2016). However, due to the rapidly growing demand for industrial robots, there is a rising concern that robot-based innovation in industrial technology could result in widespread job losses despite the fact that robotic innovation contributes to productivity. The 2016 World Economic Forum (World Economic Forum, 2016) also forecasts that the 4th Industrial Revolution will have a positive impact on the economy through improving productivity, while having a negative impact due to the increased unemployment rate worldwide. There is a possibility of job losses due to technological changes. (Frey & Osborne, 2017)

A. Yavorskiy believes that nowadays all countries, and first of all the developing ones, should seize the opportunity of transition to automated production. In the future, this approach will help their production facilities to remain relevant and competitive and contribute to the economy development. It also concerns Ukraine. In the future, the gap between the countries that have switched to automation and those that haven’t will grow rapidly (Demchenko, 2018).

According to Strassmeier K. et al. (2007) a pursuit of “robotization” is a pursuit of an integral system engineering approach that links design and engineering with operation and maintenance. Engineering problems may be similar to the problems occurring in space. However, the operations are performed on Earth, with the huge benefits of significantly lower costs, accelerated development cycles and the possibility of some interaction with humans (Strassmeier et al., 2007).

Based on the Eurobarometer survey on the attitude of Europeans to robots, scientists argue that in the near future robots are more likely to penetrate into the reproduction sectors: living conditions, healthcare, entertainment, education, communication and information, public sphere. However, so far this shift has been seen only at a descriptive level, without any attempt being made to explain why this has happened. It is time to think about the reasons that caused this shift, and as well as the ways of its manifestation (Eurobarometer, 2012)

Shunsuke Mori believes that the following new directions for the development of robots should be considered:

a. Increasing the degree of automation until a fully automated production is built, where computer-controlled machines operate with little or no human intervention;

b. robots which will perform more complex tasks due to vision, touch, force and proximity sensors;

with.

c. the use of robots for non-production operations, such as helping the disabled, geological research under water, fruit harvesting and construction work (Mori, 1989).

According to Hisashi Ishitani and Yoichi Kai, modern robots are very capable in terms of reliability, accuracy, speed and power. In the future, existing robots can be used without any improvements in their capabilities in the areas that require performing simple tasks and high processing speed, including tasks beyond human abilities, for example, hard work or high-precision work in dangerous environment (Ishitani & Kaya, 1989).

Robotization and automation have a huge economic impact. It should be noted that many scientists have different opinions about robotization and mention possible negative consequences related to the employment rate, as most work performed by people now can be done by robots. It is possible to conclude that there is no demand for unqualified employees. However, negative forecasts of job losses are based on the controversial and unreasonable assumption that the number of required workers cannot be changed. In practice, in the history of innovation, the increase in labor productivity always caused the labor market growth, rather that its reduction. It would be reasonable to expect a similar outcome of the introduction of robotics. Moreover, the preliminary experience of the introduction of robotics demonstrates this pattern. Robotization does not lead to a reduction of workplaces, but to an increased number of them. Another issue is the fact that the requirements for personnel are changing. Robots replace routine and low-skilled labor, at the same time creating the need for highly-skilled service engineers. This creates new demands for the production process organization. According to the statistics, 88% of company managers companies consider the establishment of the organization of the future to be a priority task. Flexibility plays a crucial role: companies have to replace a complex management hierarchy with the teams capable of making decisions on their own. Eighty-three per cent of managers argue about the importance of career development and training. There is no place for statics in the modern world: continuous training of employees is crucial for successful business development in the digital era. Therefore, new jobs requiring highly-qualified employees appear due to robotization. It can be stated that robots are a kind of challenge for humanity. A person needs to be well-educated and possess good personal qualities to work in a robotic enterprise.

However, economic development is one of the primary tasks for developing countries. Robotization is a great impetus to economic development. Developed economies become leaders in production robotization and automation. Robotization facilitates and accelerates many production processes. Therefore, production becomes cheaper and faster. We believe that robotization and automation are important for developing countries. But it should be noted that along with benefits, it brings increased requirements for human capital. With due attention to the development of human capital, developing countries can significantly improve their economy through robotization.

Bock, T., Parschin, D., Bulgakov, A. (2002). Robotization of mounting and finishing operations in building. Robotica, 20(2), 203-207.

Cho, J., Kim, J. (2018). Identifying factors reinforcing robotization: interactive forces of employment, working hour and wage. Sustainability, 10(2), 490.

Chui, M., Manyika, J., Miremadi, M. (2015). Four fundamentals of workplace automation. McKinsey Quarterly, 29(3), 1-9.

Demchenko, D. (2018). How robots will change the world. https://ain.ua/special/robots-vs-humans/

Eurobarometer (2012). Public attitudes towards robots (Special Eurobarometer 382). European Commission. http://ec.europa.eu/public_opinion/archives/ebs/ebs_382_en.pdf

Forge, S., Blackman, C. (2010). A helping hand for Europe: the competitive outlook for the EU robotics industry (No. JRC61539). Joint Research Centre (Seville site).

Fortunati, L. (2018). Robotization and the domestic sphere. New Media & Society, 20(8), 2673-2690.

Frey, C. B., Osborne, M. A. (2017). The future of employment: How susceptible are jobs to computerisation? Technological forecasting and social change, 114, 254-280.

Geishecker, I., Görg, H. (2008). Winners and losers: A micro‐level analysis of international outsourcing and wages. Canadian Journal of Economics/Revue canadienne d'économique, 41(1), 243-270.

Hollon, C. J., Rogol, G. N. (1985). How robotization affects people. Business Horizons, 28(3), 74-80.

Intelligent Robots Development and Distribution Promotion Act (2008). http://elaw.klri.re.kr/eng_mobile/viewer.do?hseq=17399&type=sogan&key=13

International Federation of Robotics (2016). World Robotics 2016-Industrial Robots; International Federation of Robotics Report; International Federation of Robotics: Frankfurt, Germany.

Ishitani, H., Kaya, Y. (1989). Robotization in Japanese manufacturing industries. Technological Forecasting and Social Change, 35(2-3), 97-131.

Jeong, J.H., Kim, J.H., Kim, D.B., Lee, I.J. (2011). The Aging Workforce and Pay-System Innovation. Korea Labor Institute Report; Korea Labor Institute: Geumnam-myeon, Korea.

Kennedy, S. (2015). Made in China 2025. Centre for Strategic & International Studies.

Kruglov, D.V., Vorotynskaya, A.A., Pozdeeva, E.A. (2017). Influence of robotization on the labor market. News from St. Petersburg State University of Economics, (6 (108)).

Made in China (2018). http://isdp.eu/content/uploads/2018/06/Made-in-China-Backgrounder.pdf

Micevičienė, D., Sinkevičius, V., Urbanavičiūtė, L., Henschke, M. (2015). Robotization in disabled care: projection of the impact on the economy and methodological framework evaluation. Procedia-Social and Behavioral Sciences, 213, 867-872.

Mikušová, N., Čujan, Z., Tomková, E. (2017). Robotization of logistics processes. In MATEC Web of Conferences (Vol. 134, p. 00038). EDP Sciences.

Mori, S. (1989). Macroeconomic effects of robotization in Japan. Technological Forecasting and Social Change, 35(2-3), 149-165.

Moriguchi, C. (1989). Driving Forces of Economic Structural Change: The Case of Japan in the Last Decade. In The Future of the World Economy. Springer, Berlin, Heidelberg, pp. 325-334.

Nehmzow, U. (2008). Robot behaviour: design, description, analysis and modelling. Springer Science & Business Media.

Rodnkiov, A. N. (1991). Computerization and robotization of raw material and finished product distribution in lube oil production. Chemistry and Technology of Fuels and Oils, 27(5), 239-243.

Strassmeier, K. G., Agabi, K., Agnoletto, L., Allan, A., Andersen, M. I., Ansorge, W., ... Coudé du Foresto, V. (2007). Telescope and instrument robotization at Dome C. Astronomische Nachrichten: Astronomical Notes, 328(6), 451-474.

Tokhi, M. O., Azad, A. K. (Eds.). (2008). Flexible robot manipulators: modelling, simulation and control (Vol. 68). Iet.

Watry, G. (2016). The fourth industrial revolution and robot journalism. Advantage Business Media, 21.

World Economic Forum (2016). The Future of Jobs: Employment, Skills and Workforce Strategy for the Fourth Industrial Revolution. World Economic Forum: Geneva, Switzerland.

1. Financial University under the Government of the Russian Federation, Moscow, Russian Federation; turinau168@gmail.com

2. Orenburg State University, Orenburg, Russian Federation

3. I.N. Ulyanov Chuvash State University, Cheboksary, Russian Federation

4. Northern (Arctic) Federal University named after M.V. Lomonosov, Severodvinsk, Russian Federation