HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN

HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN  Espacios. Vol. 37 (Nº 29) Año 2016. Pág. 4

Espacios. Vol. 37 (Nº 29) Año 2016. Pág. 4

Rosley ANHOLON 1; Robert Eduardo Cooper ORDÓÑEZ 2; Osvaldo Luiz Gonçalves QUELHAS 3; Dirceu da SILVA 4

Recibido: 20/05/16 • Aprobado: 22/06/2016

4. Analysis of the results and proposition of a procedure to define electives in production area

ABSTRACT: The electives are present in most engineering courses offered in Brazil and enable students to deepen their knowledge in areas of great interest. The study described in this paper aims to present an analysis procedure and the definition of the electives of production engineering for the courses of mechanical engineering, through techniques of survey as well as statistical analyses of the data. Such procedure was first implemented at School of Mechanical Engineering (State University of Campinas) and has proved to be efficient. With some adjustments, the procedure can be used by any undergraduate course manager aiming at decision-making. |

RESUMO: As disciplinas eletivas estão presentes nos cursos de engenharia oferecidos no Brasil e permitem que os alunos aprofundem seus conhecimentos em áreas de interesse. Este artigo apresenta um procedimento para a determinação de disciplinas eletivas da área de engenharia de produção para os cursos de engenharia mecânica, valendo-se do uso da técnica de survey e análise estatística. Tal procedimento foi implantado pela primeira vez na Faculdade de Engenharia Mecânica da Universidade Estadual de Campinas e provou ser eficiente. Com alguns ajustes, o procedimento pode ser usado por qualquer gestor de curso de graduação com o objetivo de tomada de decisão. |

Analyzing the curriculum of engineering programs accredited in Brazil, it is possible to note the existence of subjects entitled "elective, optional or free". According to the Brazil (2015), a subject gets this denomination when its course option happens by the free choice of the student, compared to a set of disciplines that are offered periodically. Its main objective is the further training of the student in relation to their interests and, in other situations, present topics of great relevance, who were not included in the structuring of curriculum matrices, for the training of students (Rizkalla et al. 2000).

The situation idealized by any engineering undergraduate course coordinator is to offer a wide amount of electives in different areas in order to satisfy the interest of most students, but the reality, in general, it is quite different, with budget constraints and unavailability of professors, which restrict this wide offer. Therefore, facing this reality, it appears the question of how to reconcile these constraints with the offer of electives that could be focused on the students’ interests (Jessica, 1997)

This questioning can be done to any area of any engineering course, but in this particular paper, the authors seek to focus in the interest of mechanical engineering students at the State University of Campinas (Unicamp) for electives in production engineering. It’s important to highlight that throughout the whole graduation, these students have only one compulsory subject directly related to production engineering called Production Systems (EM733) and if they want to complement their studies, this should be done through electives. Other disciplines of manufacturing engineering area just tangent the thematic of production.

Facing the above, this paper aims to answer two research problems: what are the main interests of mechanical engineering students at Unicamp in relation to production engineering issues for the offer of electives? It is possible to design a standard procedure in order to raise this information periodically?

Based on these research problems, the following objectives are designed: 1) conduct a survey with the students who attend the subject Production Systems (EM 733) in order to define the topics of greatest interest; 2) find the most appropriate statistical tools to validate the data and sort them according to students interest; 3) use this information in the offer of electives; 4) if successful, validate the procedure to be periodically used for this purpose.

When the specific literature in engineering education is analyzed, many are the papers that point out the need for more research in this field in order to understand the changes and the new ways to form new engineers (Borrego et al. 2011). Borrego and Bernhard (2011) believe that this research field must gain international forums of discussion due to its importance and the education institutions need to develop a network in order to exchange information.

According to Adams et al. (2011), discussions on effective ways to form engineers should be debated everyday by engineering professors but, unfortunately, this debate is still on a level below the ideal. The formation of the new engineer should be guided by issues such as epistemology, social justice, multidisciplinary training, leadership and greater room for innovation (Adams et al. 2011; Froyd and Ohland, 2008; Stephens et al. 2015). Coordinators of engineering courses need to use a wider approach to listen to the market's needs and the student's interests (Adams et al. 2011). For Allie et al. (2007), students of engineering courses bring a range of their own identity and aspirations that have implications for teaching and need to be identified, analyzed and exploited to allow the best training.

Clearly, the market's needs and the student's interest may differ depending on the region or country where the engineering course is offered. This aspect is highlighted by Lucena et al. (2008) on their study, where it was made a comparison between the changes that have occurred on engineering courses in the United States, Europe and Latin America, in order to meet the required competences. For these authors, the formation of engineers in the United States embrace more global competences, while the formation of engineers in Europe and Latin America deals with skills that are focused in regional needs. Streiner et al. (2015) also conducted a very interesting study on the skills required by companies and how engineering courses can contemplate them.

Regarding to the research methods used in the engineering education area, Borrego et al. (2011) point out that both quantitative and qualitative methods can be useful, whereas there is a perfect alignment between the research problem to be answered and the developed objectives.

By analyzing the literature review, it is possible to note that our study, in order to determine the offer of electives of the production engineering in mechanical engineering courses through the use of survey and technical stats, has relevance for educational engineering and that their results can be shared by other institutions.

When analyzing the literature on production engineering, there are many possible issues to be worked within them. Depending on the authors, the areas of production engineering can vary but in the end the topics are the same (Rosen, 1999; Slack et al. 2009; Corrêa and Corrêa, 2013; Ray et al. 2013; Vosniakos, 2015). As atypical example of this, one may mention the Quality area, which, for some authors, it may include besides its traditional thematic, factors associated to the environment management, health and safety and ergonomics (Slack et al. 2009).

As a way to define a single classification, the authors of this paper chose to use the classification released by the Brazilian Association of Production Engineering [ABEPRO]. The decision of using this classification was due to the fact that it is the most respectable one in Brazil and to be in accordance with other renowned international associations. Each of the eleven great areas has sub-areas with specific topics, as shown in Table 1. We use the same table to define the acronyms by which the sub-areas will be considered in the statistical analysis.

Table 1. Areas and sub-areas of Production Engineering . (Source: ABEPRO, 2016)

Areas |

Sub-areas |

Production Management

|

Production Management Systems (PM1); Methods engineering (PM2); Planning and Production Control (PM3); Logistic and Supply Chain Management and Distribution (PM4); Factory Project and Industrial Facilities (PM5); Maintenance Management (PM6); Simulation of Production (PM7); Management of Production Processes (PM8); Operations and Service Management (PM9) |

Strategic Management and Organizational |

Strategic and Operational Planning (SMO1); Production Strategies (SMO2); Industrial Organization (SMO3); Markets and Products Strategy (SMO4); Enterprises Networks and Production Chain Management (SMO5) |

Quality Management |

Statistical Quality Control (QM1); Standardization and Certification for Quality (QM2); Quality Metrological Organization (QM3); Reliability of Processes and Products (QM4); Quality Services (QM5) |

Environmental Management of the Production Process |

Natural Resources Management (EMPP1); Energy Management (EMPP2); Eco-efficiency and Cleaner Production (EMPP3); Industrial Waste Management and Pollution Prevention (EMPP4) |

Production Engineering, Sustainability and Social Responsibility |

Ethics and Transparency in Organizational Decisions (SSR1); Organizational governance (SSR2); Organizational Social Responsibility (SSR3); Sustainability and Indicator Systems (SSR4); Sustainable development in Production Engineering (SSR5) |

Ergonomics and Safety |

Design and work organization (ES1); Work Psychology (ES2); Occupational Biomechanics (ES3); Design and Management of Occupational Safety (ES4) Accident Analysis and Risk Prevention (ES5); Ergonomics Product (ES6) Ergonomics of Production Processes (ES7) |

Economic Management |

Economic Engineering (EM1); Cost Management (EM2); Financial Project Management (EM3); Investment Management (EM4); Performance of Production and Operations Systems (EM5) |

Product Management |

Market Research (PROD1); Product Planning (PROD2); Product Design methodology (PROD3); Product Engineering (PROD4); Marketing of the Product (PROD5) |

Operational Research |

Mathematical Programming (OR1); Multicriteria decision (OR2) Stochastic Processes (OR3); Modeling, Analysis and Simulation (OR4); Decision Theory and Game Theory (OR5); Demand Analysis by Products (OR6) |

Organizational Knowledge Management |

Innovation Management (OKM1); Management of Technology (OKM2); Production Management and Operations Information (OKM3); Project Management (OKM4) Knowledge Management in Productive Systems (OKM5) |

Education in Production Engineering |

Study of the Production Engineering Education (EPE1); Development and Application of Research in Industrial Engineering (EPE2); Study of Professional Practice in Production Engineering (EPE3) |

The description of the stages performed to conduct the research is presented on Table 2. The research began with the definition of the problem issue, which headed our whole study and was presented in the introduction. In the sequence, it was performed a literature review in order to generate greater knowledge on the theme and to verify the existence of similar papers written by other authors. As the theme was directly related to education in engineering, the literature review considered professional journals such as the International Journal of Educational Engineering and none of them addressed the issue presented here, which demonstrate the originality of our paper.

Table2. Stages performed to develop the research (Source: authors)

Nº |

Steps |

1 |

Development of the research problem |

2 |

Literature review in journals related to education in engineering. |

3 |

Development of research tool (questionnaire) considering the areas and subareas of ABEPRO (2016). |

4 |

Sample selection and implementation of the survey with 97 students of production subjects. |

5 |

Tabulation of the data and statistical analysis of the results. |

6 |

Establishment of conclusions and proposition of a method. |

7 |

Final writing of the text. |

In order to enable the survey development, a questionnaire was structured considering the areas and subareas of production engineering broadcast by ABEPRO (2016). Note that for each subarea, the questioned students should select the degree of interest through a scale ranging from 1 to 10, where 1 is a low interest in the subarea and 10 is the maximum interest in the subarea. To facilitate the data collection, the questionnaire was made available to students through Google Forms tool.

The analyzed sample consisted of the mechanical engineering students from Unicamp who were finishing the Production Systems discipline in 2015. This course takes four hours per week, lasts one semester and it is the only compulsory subject with production engineering content, which is offered to the students of Mechanical Engineering Faculty. It’s worth saying that some other concepts are taught in manufacturing engineering subject but in these cases the focus is more restricted. When there is an additional interest by the students in relation to topics directly linked to production engineering, this need is fulfilled through the provision of electives. The catalog of undergraduate courses presents a good range of elective courses in that area, but the offer was not aligned with the student's interests. Altogether, 97 students in three different classes answered in the survey.

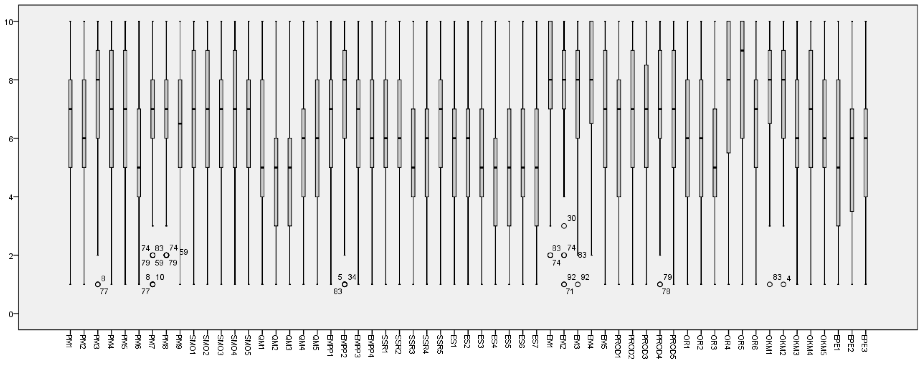

The survey was available online for the students during a month and after that, the data tabulation and the statistical analysis were performed. The statistical analysis evaluated three main points: data reliability through Cronbach’s alpha coefficient, elimination of outliers points through boxplot and creating a ranking of interest subareas using the Exploratory Factor Analysis. All these statistical analyze were performed using SPSS software (Statistical Package for Social Sciences) version 22.

According to Malhotra (2012), the Cronbach’s alpha coefficient allows one to check the internal consistency of data set collected. A coefficient above 0.70 indicates internal reliability of the data collected (Hair et al, 2009).

The boxplot is a graphical tool to assess the symmetry of the data, their dispersion and the existence of outliers and it is especially suitable for comparing two or more sets of data (Hair et al, 2009). Outliers points are data that are located far from the other observations of a statistical series (Malhotra, 2012). The parameters used to eliminate outliers points in SPSS 22 were: charts, simple box charts, summary of separate variables, for missing values exclude cases per list.

The Exploratory Factor Analysis (EFA) allows one to explore a set of data, seeking a simplification of the presented information, meaning, aiming a reduction of the number of factors in order to facilitate the analysis (Hair et al, 2009). According to King (2014), Hair et al. (2009) and Filho and Junior (2010) when it is held for a single fixed factor, the variables are classified based on the generated scores. Importantly, the scores generated by AFE present an average of zero and a standard deviation equal to one (Filho and Junior, 2010). The parameters used to create the ranking based on SPSS 22 were as follows: extraction by the method of the main components of the correlation matrix analysis, single factor, maximum number of iteration equal 25, varimax rotation method and regression method for scores.

After all the statistical analyzes were performed, the debate of the results and the definition of the subareas of student’s greater interest have started. This information was used to validate a standard procedure to be periodically applied in the Mechanical Engineering Courses at Unicamp, in order to find out the interests of their students related to the areas of Production Engineering.

The presentation of the results will follow the parameters defined in the methodological procedures item. The data from the 97 collected questionnaires were subjected to Cronbach's alpha coefficient, in order to test their internal consistency. The results obtained by the SPSS 22 software showed a coefficient of 0.8930 providing the reliability of the collected data. Once again, it is emphasized that Malhotra (2012) suggests indices higher than 0.70.

The elimination of outliers points was performed using the boxplot and demonstrated 14 extreme points (students 4, 5, 8, 10, 30, 34, 59, 71, 74, 77, 78, 79, 83 and 92). In this situation, the researcher has two possibilities: 1) eliminate only the data in the respective issue and replace it for the average 2) eliminate the complete questionnaire. Considering that we have a good sample and assuming these outliers could harm the samples in another way, we decided to eliminate de 14 questionnaire and to valid 83 questionnaire. Figure 1 highlights the use of boxplot to define outlier points.

Figure 1. Use of boxplot to define outlier points (Source: authors)

The answers attributed by the 83 valid questionnaires were submitted to Exploratory Factor Analysis for a single factor, creating scores with a zero average and a standard deviation equals to one. These scores were used to order the production engineering subareas according to student's interest, as it possible to see in Table 3. See Table 1 for acronyms.

Table3. Production Engineering Subareas ordered according student's interest (Source: authors)

Order |

Score EFA |

Subarea |

Order |

Score EFA |

Subarea |

Order |

Score EFA |

Subarea |

1º |

1.66091 |

EM1 |

21º |

0.5955 |

PM5 |

41º |

-0.5615 |

SSR1 |

2º |

1.6482 |

EM4 |

22º |

0.56847 |

SMO4 |

42º |

-0.71393 |

SSR4 |

3º |

1.62746 |

OR5 |

23º |

0.49577 |

PM4 |

43º |

-0.71698 |

EPE2 |

4º |

1.43682 |

EM2 |

24º |

0.47778 |

EMPP2 |

44º |

-0.73552 |

QM4 |

5º |

1.35461 |

EM3 |

25º |

0.4553 |

SMO3 |

45º |

-0.76884 |

OR3 |

6º |

1.21282 |

OKM1 |

26º |

0.43238 |

PROD5 |

46º |

-0.8529 |

EPE3 |

7º |

1.17133 |

OKM2 |

27º |

0.41638 |

OKM5 |

47º |

-0.85345 |

EPE1 |

8º |

1.1422 |

OKM4 |

28º |

0.34494 |

PROD3 |

48º |

-0.87571 |

PM6 |

9º |

1.13526 |

PM3 |

29º |

0.22616 |

OKM3 |

49º |

-0.91975 |

QM1 |

10º |

1.06602 |

PM1 |

30º |

0.11739 |

EMPP3 |

50º |

-0.9505 |

SSR3 |

11º |

0.85099 |

OR4 |

31º |

0.07683 |

OR2 |

51º |

-0.99322 |

ES1 |

12º |

0.83282 |

SMO1 |

32º |

0.03541 |

PM2 |

52º |

-1.22936 |

ES2 |

13º |

0.79376 |

PROD4 |

33º |

0.01633 |

PROD1 |

53º |

-1.47102 |

ES6 |

14º |

0.7837 |

EM5 |

34º |

-0.02265 |

PM9 |

54º |

-1.65795 |

ES3 |

15º |

0.7415 |

SMO2 |

35º |

-0.0785 |

SSR5 |

55º |

-1.70276 |

ES5 |

16º |

0.69345 |

SMO5 |

36º |

-0.36847 |

EMPP1 |

56º |

-1.73957 |

QM2 |

17º |

0.67991 |

PM8 |

37º |

-0.44106 |

EMPP4 |

57º |

-1.87479 |

ES7 |

18º |

0.62513 |

OR6 |

38º |

-0.46222 |

OR1 |

58º |

-1.9653 |

ES4 |

19º |

0.62263 |

PROD2 |

39º |

-0.48527 |

SSR2 |

59º |

-2.0056 |

QM3 |

20º |

0.59694 |

PM7 |

40º |

-0.48827 |

QM5 |

As shown in Table 3, the ten subareas of greatest interest are associated with Economic Management areas (4 items: Economic Engineering - EM1; Investment Management - EM4; Cost Management - EM2 and Financial Project Management - EM3), Organizational Knowledge Management (3 items: Innovation Management - OKM1, Technology Management - OKM2 and Project Management - OKM4) Production Management (2 items: Planning and Production Control - PM3 and Systems Management Production - PM1) and Operational Research (Decision and Game Theory - OR 5).

These issues are not presented in depth in the mechanical engineering course and perhaps the students of the discipline Production Systems may feel these needs. Moreover, the discipline is allocated in 7th semester, when many students have already started internships in companies in the region and this may influence their choices with greater maturity to them.

Currently, the course of Mechanical Engineering at Unicamp has elective courses with formally defined content and others of topics, whose content is defined according the needs. To these electives with topics, the catalog presents this definition "broader and deeper approach to a particular matter of Engineering in the Production area." This discipline is known by the acronym EM999 and can be used to align the student's interests with the topics mentioned above. So, for the next semesters, the offer of elective courses in the production engineering area could focus contents as "Discipline 1: Game Theory," "Discipline 2: Innovation and Technology in Production Processes Project" and "Course 3: Management economical Production Processes ".

When analyzing the ten subareas of less interest, it was also possible to establish interesting conclusions. There is a negative emphasis on the Ergonomics and Safety area (all items in the order ES1, ES2, ES6, ES3, ES5, ES7 and ES4) and Quality Management (two items in the order QM 2 and QM 3). The coordinator of the course must question himself the reason for that low interest, if it’s only due to a matter of students' fitness or if there are didactic problems in addressing these contents. It is notorious for any researcher in Production Engineering area, the importance of these issues and it may be necessary to strengthen throughout the whole graduation their importance for Production Engineering.

Thus, based on the study developed and the consistency of the gathered information, the authors of this paper propose a procedure to define the student's interest in topics of the production area as well as to define strategies to offer electives and reviews. This procedure is presented in Table 4.

Table 4. Procedure to define student's interest in topics of the production area

(Source: authors)

nº |

Step |

1 |

Conduct a survey with questionnaire according production engineering areas and subareas broadcasted by ABEPRO (2016). |

2 |

Data tabulation and analysis of internal reliability through Cronbach's alpha coefficient. |

3 |

Elimination of outliers points using boxplot |

4 |

Ordination of production engineering sub-areas through the scores generated by Exploratory Factor Analysis to a single factor. |

5 |

Analysis of the subareas with best scores, checking the existence of electives with these comments or propose topics of disciplines (EM999). |

6 |

Analysis of less interest subareas, seeking to verify if the indexes are indeed derived only from the student's indifference or from teaching problems along the graduation. |

7 |

Offer electives and propose improvements in the course, if necessary. |

Based on the observed results, one may conclude that the procedure presented by this paper is effective to determine the content of elective courses in production engineering area to be offered to mechanical engineering students of Unicamp. This procedure allowed us to determine that the student’s main interests are related to the areas of Economic Management, Organizational Knowledge Management, Production Management and Operational Research. Based on this information, the course coordinator was able to make a better projection of the offer of the electives for the next semesters.

As a complement, the proposed procedure also enabled the identification of the topics where the students had less interest. In the analyzed sample, these topics were related to ergonomics areas, quality management and metrology. It is up to the course coordinator to verify if this disinterest is due to the students behavior or if there any are didactic problems.

This procedure was firstly implemented in the mechanical engineering course of Unicamp in 2015 and this information will be refined over time. The authors of the paper believe that with the periodic repetition of this procedure it will be possible to create a database with information that can be used for different purposes such as events or curriculum restructuring.

As a proposal of new research, the authors highlight yet that with the appropriate adjustments in the questionnaire, the procedure can be used within any engineering course.

ABEPRO. (2016). Brazilian Association of Production Engineering. Available at http://www.abepro.org.br. Access, April 12, 2016.

Adams, R. et al. (2011). Multiple Perspectives on Engaging Future Engineers. Journal of Engineering Education, 100 (1), 48-88.

Allie, S., Armien, M.N., Bennie, K., Burgoyne, N., Case, J., Craig, T., Wolmarans, N. (2007). Learning as acquiring a discursive identity through participation in a community: A theoretical position on improving student learning in tertiary science and engineering programmes: Cape Town: Centre for Research in Engineering Education (CREE), University of Cape Town

Borrego, M., Bernhard, J. (2011). The Emergence of Engineering Education Research as an Internationally Connected Field of Inquiry. Journal of Engineering Education. 100 (1), 14-47.

Borrego, M., Douglas, E.P., Amelink, C.T. (2011). Quantitative, Qualitative, and Mixed Research Methods in Engineering Education. Journal of Engineering Education, 98 (1), 53-66.

Brazil. Ministry of Education. (2016). Available at http://www.mec.gov.br. Access, April, 14 2016.

Corrêa, H.L., Corrêa, C.A. (2013). Administração de Produção e Operações. Manufatura e serviços: uma abordagem estratégica. São Paulo: Editora Atlas.

Filho, D.B.F.; Junior, J.A.S. (2010). Visão além do alcance: uma introdução à análise fatorial. Opinião Pública. 16 (1), 160-185.

Froyd, J.E., Ohland, M.W. (2008) Integrated Engineering Curricula. Journal of Engineering Education. 94 (1), 147-164.

Hair Jr, J.F., Black, W.C., Babin, B.J., Anderson, R.E., Atham, R. (2009). Análise Multivariada de Dados. Porto Alegre: Editora Bookman.

Jessica, N.G. (1997). Should Law be Introduced into the Engineering Curriculum? International Journal of Educational Engineering, 11 (1) 72-78.

King, G. (2014). How not to lie with statistics. NY University. Available at http://gking.harvard.edu/files/mist.pdf. Access, January 14, 2016.

Lucena, J., Downey, G., Jesiek, B., Sharon, E. (2008). Competencies Beyond Countries: The Re-Organization of Engineering Education in the United States, Europe, and Latin America. Journal of Engineering Education, 97(4), 433-447.

Malhotra, N. (2012). Pesquisa de Marketing: uma orientação aplicada. Porto Alegre: Editora Bookman.

Ray, B.; Bhaskaran, R. (2013). Integrating simulation into the engineering curriculum: a case study. International Journal of Mechanical Engineering Education, 41 (3), 269-280.

Rizkalla, M.E.; Yokomoto, C.H.; Pfile, R.; Sinha, A.S.C.; El-Sharkawy,M.; Lyashevskiy, S; Needler, M. A. (2000). New Approach for an Interdisciplinary Senior Elective for Electrical Engineering and Electrical Engineering Technology Majors in Electric Vehicle Applications. International Journal of Educational Engineering. 16 (4), 351-361.

Rosen, M.A. (1999). Teaching the environmental impact of industrial processes. International Journal of Mechanical Engineering Education, 29 (1), 39-52.

Slack, N., Chambers, S., Johnston, R. (2009). Administração da produção. São Paulo: Editora Atlas.

Stephens, C. M; Rosch, D.M. (2015). Building Leaders: A National Examination of the Leadership Capacities within Engineering Undergraduate Student. International Journal of Educational Engineering. 31 (4), 986-997.

Streiner, S. C.; Vila-Parrish, A.R.; Warnick, G.M. (2015). An Exploratory Study of Global Competencies Considered by Multinational Companies: A Hiring Perspective. International Journal of Educational Engineering, 31 (5), 1239-1254.

Vosniakos, G.C. (2015). Teaching manufacturing systems integration through data modelling and network exchange simulation. International Journal of Mechanical Engineering Education, 31 (2), 113-131

1. Professor at School of Mechanical Engineering, Department of Manufacturing Engineering and Materials (DEMM). State University of Campinas, Campinas, São Paulo, Brazil. 200; e-mail: rosley@fem.unicamp.br

2. Professor at School of Mechanical Engineering, Department of Manufacturing Engineering and Materials (DEMM). State University of Campinas, Campinas, São Paulo, Brazil. 200; e-mail: cooper@fem.unicamp.br

3. Professor at Laboratory of Technology, Business Management and Environment (LATEC). Federal Fluminense University, Niteroi, Rio de Janeiro, Brazil. 156, Passos da Pátria; e-mail: quelhas@latec.uff.br

4. Professor at Laboratory of Innovation Technology Applied. Faculty of Education, State University of Campinas, Campinas, São Paulo, Brazil. 801, Bertrand Russell Avenue; e-mail: dirceuds@gmail.com