Vol. 39 (Number 18) Year 2018 • Page 29

ZHANDARBEKOVA Assel 1; SARZHANOV Dauren 2; MURZABEKOVA Kenzhegul 3; TULENDIEV Erlan 4

Received: 20/01/2018 • Approved: 15/02/2018

ABSTRACT Relevance. In modern conditions, the world market puts ever more stringent requirements for engineering products. Practice shows that the market economy forces to create more and more perfect models of machines by selecting a small number of best models and further improving from the viewpoint of reducing downtime in repairs. In this regard, the relevance of this work is due to the need to maintain the required level of reliability of machines at the optimal level of costs for operating repair of assemblies. |

RESUMEN Pertinencia. En condiciones modernas, el mercado mundial exige requisitos cada vez más estrictos para los productos de ingeniería. La práctica muestra que la economía de mercado obliga a crear modelos de máquinas cada vez más perfectos seleccionando un pequeño número de mejores modelos y mejorando aún más desde el punto de vista de reducir el tiempo de inactividad en las reparaciones. En este sentido, la relevancia de este trabajo se debe a la necesidad de mantener el nivel requerido de confiabilidad de las máquinas al nivel óptimo de costos para la reparación operativa de ensamblajes. Objetivo: Reducir los costos unitarios totales mínimos para mantener la confiabilidad de las máquinas en operación. Tareas de investigación: mediante el modelado por computadora, determine los límites del aumento óptimo en la confiabilidad de piezas y conjuntos de transmisión que fallan con frecuencia en los cargadores frontales de un solo cucharón. Objeto de estudio: Partes y subconjuntos que limitan la confiabilidad de la transmisión hidromecánica del tren motriz de los cargadores frontales de cuchara única L-34B, 534C. Diseño de la investigación. Los métodos de la teoría de confiabilidad de sistemas técnicos, la teoría de la restauración de la operabilidad de productos reparados y los métodos de simulación computarizada de indicadores de confiabilidad de la máquina se aplican a los procesos de restauración de la operatividad de piezas y ensamblajes de acuerdo con la teoría básica leyes Resultados. Se determinan los parámetros para la distribución de fallas de subconjuntos y partes que limitan la confiabilidad del objeto de investigación. Se revelan los límites del aumento óptimo en los indicadores de confiabilidad de las piezas con falla frecuente y los componentes de transmisión del SB-165-2. Se ha establecido que para los grupos de partes menos confiables de la transmisión SB 165-2, la durabilidad puede aumentarse en el rango 2.0-2.5. Para aumentar la fiabilidad del conjunto considerado, se propone reducir el número de reparaciones operativas emitiendo recomendaciones para mejorar la confiabilidad de los grupos de piezas menos confiables, poco confiables e insuficientemente confiables para los reemplazos de articulaciones. |

At present, a significant improvement in the technical indicators of machinery and equipment is required to increase their potential. At the same time, machines and equipment, constructively, become more complex and, as a consequence, more and more labor and material costs are required for their production and operation. The costs of maintaining and restoring the operability of construction and road machines are 6-10 times higher than the cost of a new machine [1].

In this regard, increasing the reliability of machines in operation is a task of great practical importance. At the same time, an important factor is the universality of the machines and equipment in terms of functionality. For numerous enterprises, it is important that the machine purchased can not only produce earthmoving, planning and loading and unloading works, but also be suitable for carrying out a wider range of works. The main part of the fleet of modern machines for the construction of industrial facilities, transport facilities, etc. are SBFLs (single-bucket front loader) equipped with HMD (hydro-mechanical drivetrain), which have become widespread due to their inherent advantages [2,3]. The main feature of the SBFLs operation is the fact that in performing a number of works they replace excavators, bulldozers and other machines, because their ability to perform a wide range of work [4–8].

It should be noted that increasing the reliability and improving the operation of the SBFLs is a large reserve that allows to increase their productivity, to exclude downtime during planned and unplanned repairs.

The practice of the SBFLs operation at industrial facilities in East Kazakhstan shows that some machines are often out of service and for a long time, require constant intervention of maintenance personnel in order to replace failed parts and assemblies.

The increase in reliability of SBFL is primarily due to a reduction in the total unit costs for the acquisition of machines and maintenance of their operability in operation. This is achievable when using a system of group substitutions of parts and components that limit its reliability. Within it, one should strive to ensure that each of the parts of the machines can be restored independently of the others.

Implementation of this approach requires the development of methods to increase reliability, primarily, aggregates and assemblies that limit the reliability of the SFBL. Based on the operational tests of SFBL L-34B and 534C, it is revealed that the efficiency of their operation depends to a large extent on the state of HMT, in which the gearbox (GB) 8 is the least reliable unit. GB reasons to 93.98% of HMT failures.

It should be noted that the traditional methods of ensuring the reliability of HMT, based on the system of preventive maintenance, do not provide the full necessary result on the one hand, and on the other - lead to greater material and financial costs of operating enterprises. It is established that the existing methods of ensuring reliability and organization of repairs of HMT OPF do not allow providing the most effective, from the point of view of economics, resource-saving in the field of managing the processes (system) of maintaining efficiency.

Thus, the current situation determines the need for a scientifically grounded approach in order to improve the reliability of machines.

With the help of methods of reliability theory, it is possible to solve the problems of ensuring the reliability of construction machinery, equipment and mechanisms at different stages of the life cycle of machines and mechanisms. In this case, the general approach to the estimation of reliability of technical objects is based on the interpretation of the failure [10].

In accordance with the developed mathematical model for calculating the reliability indices of technical systems, computer simulations were carried out. At the same time, a computer program was developed that makes it possible to perform the corresponding calculations, including with respect to distributions of the parts operating time under Normal law, Weibull law, and Erlang law. The calculation of the following reliability indicators for the L-34B and 534C front loaders is performed: the operating time to the first failure, the minimum total unit costs for maintaining reliability, the optimum resource and the level of reliability. During the calculation of the costs of maintaining operational reliability, the nature of the operating repair work was taken into account when eliminating the failures of the TM and the regularities of the processes of restoring its operability. Calculation of the leading function of the failure flow is carried out with respect to the processes of restoring the machine’s operability, including the general nonstationary process with the help of the developed refined computer modeling program.

To increase the level of reliability of the machine assembly, it is proposed to reduce the number of operating repairs by improving the reliability of the least reliable, unreliable and insufficiently reliable groups of parts of joint replacements. For this purpose, computer modeling was performed to increase the resource and cost parameters of the most frequently failing groups of parts of the SB 165-2 TM.

Modeling the costs of maintaining operational reliability is based on the nature of the change in failure, i.e. based on the leading function of the failure flow [22]. At the same time, the reliability index of SB 165-2 TM is taken into account as a whole.

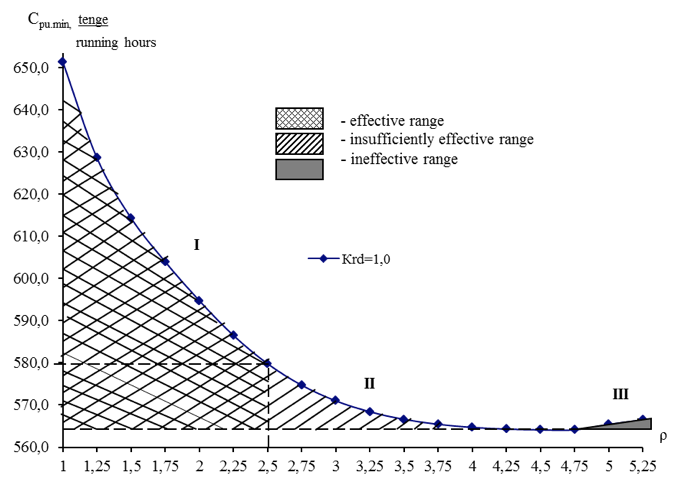

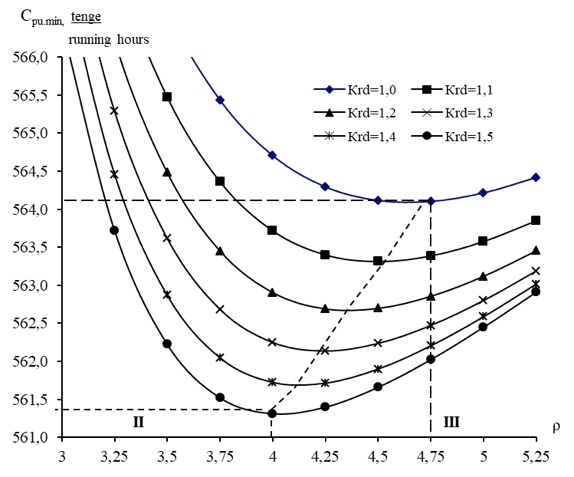

Fig 1

Dynamics of the minimum total specific costs depending on the resource

change of the least reliable parts group of the SB 165-2 transmission

Fig 2.

Dynamics of the minimum total average specific costs depending on the resource

change and dispersion of its least reliable parts group of the SB 165-2 transmission

It has been established that in order to reduce the number of repairs to the SB 165-2, in order to reduce the corresponding costs, it is necessary to ensure equal (multiple) durability of the parts included in the general design and technological group. At the same time, the proposed approaches allow estimating the limits of the increase in the longevity indexes of parts that limit its reliability, with a significant increase in the reliability level of the GB SB 165-2 control unit as a whole and a reduction in the costs of maintaining its operability in operation.

As a result of computer simulation of the reliability level of the least reliable group of parts, GB SB 165-2 defines the limit of its improvement. Similar results for the calculation of the minimum total unit costs, the level of reliability of the GB SB-2-2-2 were obtained for the other groups of parts under consideration.

The results of this study made it possible to determine the limits of the optimum increase in the reliability indices of the frequently failing groups of parts of GB SB 165-2. In particular, for the least reliable groups of parts of GB SB 165-2, the durability can be increased in the range 2.0-2.5. It is established that it is possible to reduce the minimum total unit costs for maintaining the reliability of the aggregate under review to 15.1%.

1. Kutuzov V.V. Effektivnost’ ekspluatatsii stroitel'nykh i dorozhnykh mashin s uchetom izmeneniya ikh tekhnicheskogo sostoyaniya//Tekhnologiya kolesnykh i gusenichnykh mashin. Nauchno-issledovatel’skiy institut konstruktsiy avtomobiley (Moskva). – 2015. – No. 3 (19). – P. 57-64.

2. Griff M.I., Kaganovich Ye.M., Kazimirov L.P., Yagudayev L.M. Pogruzchiki Mira: Spravochnik. – M.:Izd-vo Assotsiatsiya stroitel’nykh vuzov. – 2005. – Vol. 10. – 216 p.

3. Chellini R. New driveline for mini wheel loaders// Diesel Progress International Edition. 2004. – Vol. 23. – Iss. 2. - р. 75 (internet resource https://www.scopus.com/).

4. Dolgikh Ye. S., Makhno D. Ye. Analiz nadezhnosti frontal’nykh pogruzchikov na gornodobyvayushchikh predpriyatiyakh severa// Vestnik irkutskogo gosudarstvennogo tekhnicheskogo universiteta. – 2014. – No. 6 (89). - P.54-59.

5. Roskam R., Dobkowitz D. Modeling of a front-end loader for control design// 2015 23rd mediterranean conference on control and automation (MED). - 2015.– рр. 442-447 (internet resource https://www.scopus.com/).

6. Senthil Kumar, P.S., Srinivasan, P. , Palati, K.K. , Mallela, G. Design, development and evaluation of dual belleville clutch in front end loader tractor for clutch life enhancement//International Journal of Mechanical and Mechatronics Engineering. - 2015. – Vol. 15. - № 1. – рр. 79-88 (internet resource https://www.scopus.com/).

7. Nilsson, T., Fröberg, A., Åslund, J. Predictive control of a diesel electric wheel loader powertrain// Control Engineering Practice. - 2015. –Vol. 41. - рр. 47–56 (internet resource https://www.scopus.com/).

8. Zhandarbekova A.M. Formirovaniye ratsional’nogo kompleksa tekushchego remonta korobki peredach odnokovshovykh frontal’nykh pogruzchikov/ Izvestiya Tomskogo politekhnicheskogo universiteta. – 2014. – Vol. 324. – №2. – P. 52-55.

9. Nadezhnost’ mashin i mekhanizmov: Uchebnik/V.A. Cherkasov i [dr], pod red. B.A. Kaytukova i V.I. Skelya; M-vo obrazovaniya i nauki Ros. Federatsii, nats. issledovat. Mosk.gos. stroit. Un-t Moskva: NIU MGSU, 2015. - 272 p.

10. August G., Baratta A., Casciati F. Probabilistic methods in structural engineering. - London: Chapman and Hall. - 1984. - 556 p.

11. Beichelt F. Replacement policy based on the maintenance cost rate// JEEE Trans. Reliab. -1982. - R-31. - рр. 391-393.

12. Franken P., Streller A. Reliability analysis of complex repairable systems by means of marked point processes.// J. Appl. Probab. - 1980. – № 17. - рр. 154-167.

13. Boland P.J., Proschan F. Periodic replacement with increasing costs at failure. FSU Statist. Report № M578 / AFORCE Technical Report. - 1981. - рр. 78-123.

14. Tadikamala P.R. Age replacement policies for Weibull failure times// JEEE Trans. Realiab. - 1980. – V.R-29.- Iss.1. - рр. 88-90.

15. Sheynin A. M. Zakonomernosti vliyaniya nadezhnosti mashin na effektivnost' ikh ekspluatatsii. M.: Znaniye. - 1987. - 54 p.

16. Sheynin A.M., Sheynin V.A. Modeli optimizatsii normativov nadezhnosti mashin i ikh konstruktivnykh elementov // Optimizatsiya protsessov ekspluatatsii stroitel’nykh i dorozhnykh mashin: Sb. nauch. tr. / MADI-M. – 1983.

17. Kul'seitov ZH.O., Lis’yev V.P. Matematicheskiye modeli i podderzhaniye nadezhnosti mashin. – Almaty: Gylym. – 1996. – 222 p.

18. Kulseitov ZH.O., Lis’yev V.P. Issledovaniya v oblasti protsessov vosstanovleniya rabotosposobnosti mashin//Izv. NAN RK: Ser. Fiz-mat. Nauk. – 1993. –No.3. – P. 71-75.

19. Dzholdasbekov U.A., Kulseitov ZH.O. Vosstanovleniye rabotosposobnosti mashin i mekhanizmov vysokikh klassov// Dokl. MN-AN RK. – 1997. – No.2. – P55-60.

20 Verigin YU.A., Kulseitov ZH.O., Zhandarbekova A.M. K resheniyu voprosa sokrashcheniya ob”yemov tekushchego remonta korobki peredach pogruzchikov modeley L-34B i 534S./ Izvestiye Vysshikh uchebnykh zavedeniy «Stroitel'stvo» Novosibirsk 2012, No. 10 (646) P. 74-80.

21. Parts catalog 534С Serial NUMBERS 20001 And UP DRESSTA Co. LTD. AJOINT VENTURE OF KOMATSU AMERICA INTERNATIONAL CO END HUTA STALOWA WOLA S.A.CATALOG CZESCI PARTS CATALOCUE.

22. Zhandarbekova A.M. Povysheniye urovnya nadezhnosti dorozhno-stroitel'nykh mashin i effektivnost' ikh ekspluatatsii./ Respublikanskiy nauchnyy zhurnal «Nauka i obrazovaniye yuzhnogo Kazakhstana». 2012. – Shymkent, 2012 – No.3/4 P. 164-167.

1. Ph.D. of Engineering Science, Senior Lecturer at the S. Seifullin Kazakh Agro-technical University. E mail: AZhandarbekova@bk.ru

2. Ph.D. of Engineering Science, Senior Lecturer at the L.N. Gumilyov Eurasian National University. Email: dauren78@mail.ru

3. Ph.D. of Engineering Science, Associate Professor at the Kazakh Academy of Transport and Communications named after M. Tynyshpayev. E mail: mkaken@mail.ru

Ph.D. of Engineering Science, Senior Lecturer at the S. Seifullin Kazakh Agro-technical University. E mail: erlanktz@gmail.com